23rd Aug 2010, 14:16

permalink Post: 82

Approach handling was an interesting exercise - being so far down the back of the drag curve (over 100kts below best L/D) very accurate thrust handling was required.

The autothrottle was always used for approach if servicable, except for a two-engined approach, and was absolutely excellent. There were two, operating in parallel, and if the speed was more than a couple of knots out for more than a few seconds it was unusual. In IAS ACQ mode there was an active input from the INS which tracked grounspeed and so enabled anticipatory throttle movements during wind changes - if an autoland runway was available the preferred method of dealing with an approach likely to experience windshear was to carry out an autoland. (I think I speak for everyone, though, if I express a preference for the just going somewhere else option).

In Supercruise one autothrottle only was rearmed if the associated autopilot was engaged - it wasn't active but was available to cater for sudden drops in temperature which could cause unpleasant sudden high rates of climb if the temp shear was sufficient.

The rest of the flight - basically manual thrust, usually with the throttles fully forward.

Maybe one day we'll start making aeroplanes with such sophisticated systems again...........there's still lots that hasn't been hinted at on this thread

The autothrottle was always used for approach if servicable, except for a two-engined approach, and was absolutely excellent. There were two, operating in parallel, and if the speed was more than a couple of knots out for more than a few seconds it was unusual. In IAS ACQ mode there was an active input from the INS which tracked grounspeed and so enabled anticipatory throttle movements during wind changes - if an autoland runway was available the preferred method of dealing with an approach likely to experience windshear was to carry out an autoland. (I think I speak for everyone, though, if I express a preference for the just going somewhere else option).

In Supercruise one autothrottle only was rearmed if the associated autopilot was engaged - it wasn't active but was available to cater for sudden drops in temperature which could cause unpleasant sudden high rates of climb if the temp shear was sufficient.

The rest of the flight - basically manual thrust, usually with the throttles fully forward.

Maybe one day we'll start making aeroplanes with such sophisticated systems again...........there's still lots that hasn't been hinted at on this thread

24th Aug 2010, 15:25

permalink Post: 93

M2dude

,

Thanks for bringing up the story of the temperature shears at low latitudes, saves me some explaining !

The phenomenon was not really "discovered" until the route proving started.

As you say, it meant abrupt changes in Mach and Tt.

Since the pitch autopilot in, say, 'Mach Hold', had only one way to cope with those changes : pitching up or pitching down, this resulted in abrupt climb and descent manoeuvres that were totally inacceptable.

It was not only fixed by modifiying the intake controls.... !

It also led to a fairly major mod in the AFCS, by bringing the auto-throttle into the loop.

Instead of letting the pitch A/P take the aircraft into a zoom climb to try and stay within the "speed limits", it woold be the autothrottle pulling the throttles back.

After a fair amount of flight tests, this became the final form of the 'Max Cruise' mode.

I know... I should have kept a diary.

All this happened 35 years ago, so I can't put exact dates, or even specific aircraft, into the story. At least I still have some Concorde doc, that at times allows me to refresh my memory.

But one thing stayed in my memory over the years ...

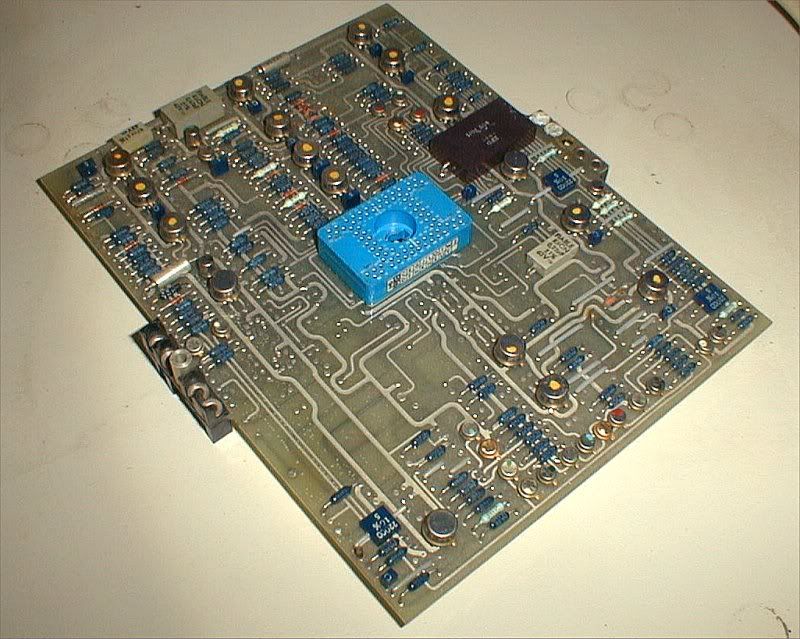

The initial A/P+A/T 'Max Cruise' mod meant a major modification of the autothrottle computers. One of the circuit boards in particular was totally "butchered" on-site (Fairford), with well over a hundred track cuts and new wire links, not to mention the number of component changes (to give an idea to the 'experts', these were double-sided PCBs of about 15x20cm).

We got the job done (4 boards : 2 boards per computer, 2 computers), got the computers tested and on the aircraft. Knowing full well how easy it was to introduce faults and problems during such a modification (a dud solder joint could be enough), we expected to see them back within days, or at least within a few flights.

Well..... those computers left the lab with each about a thousand hours "on the clock" (they have little elapsed-time counters that indicated hours under power, NOT flight hours).

The first time we saw them back (for a minor mod, not a fault), both clocks showed over 10,000 hours !

Ah, those were the days

CJ

Thanks for bringing up the story of the temperature shears at low latitudes, saves me some explaining !

The phenomenon was not really "discovered" until the route proving started.

As you say, it meant abrupt changes in Mach and Tt.

Since the pitch autopilot in, say, 'Mach Hold', had only one way to cope with those changes : pitching up or pitching down, this resulted in abrupt climb and descent manoeuvres that were totally inacceptable.

It was not only fixed by modifiying the intake controls.... !

It also led to a fairly major mod in the AFCS, by bringing the auto-throttle into the loop.

Instead of letting the pitch A/P take the aircraft into a zoom climb to try and stay within the "speed limits", it woold be the autothrottle pulling the throttles back.

After a fair amount of flight tests, this became the final form of the 'Max Cruise' mode.

I know... I should have kept a diary.

All this happened 35 years ago, so I can't put exact dates, or even specific aircraft, into the story. At least I still have some Concorde doc, that at times allows me to refresh my memory.

But one thing stayed in my memory over the years ...

The initial A/P+A/T 'Max Cruise' mod meant a major modification of the autothrottle computers. One of the circuit boards in particular was totally "butchered" on-site (Fairford), with well over a hundred track cuts and new wire links, not to mention the number of component changes (to give an idea to the 'experts', these were double-sided PCBs of about 15x20cm).

We got the job done (4 boards : 2 boards per computer, 2 computers), got the computers tested and on the aircraft. Knowing full well how easy it was to introduce faults and problems during such a modification (a dud solder joint could be enough), we expected to see them back within days, or at least within a few flights.

Well..... those computers left the lab with each about a thousand hours "on the clock" (they have little elapsed-time counters that indicated hours under power, NOT flight hours).

The first time we saw them back (for a minor mod, not a fault), both clocks showed over 10,000 hours !

Ah, those were the days

CJ

24th Aug 2010, 21:30

permalink Post: 98

Modern LSI surface mounted, multi layer electronics.

First of all, many, many thanks to our four main sources of Concorde 'nectar'; M2Dude, ChristiaanJ, Bellerophon and Exwok. Their input, each from a slightly different viewpoint, is absolutely captivating. As fascinating as the lady herself.

Christiaan rang an awful lot of bells with his description of some of the electronics - it was very, very similar to the stuff I used to work on, back in the early days of production CT Scanners. Cut tracks and wire links were the 'staff of life' and the stuff of nightmare.

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!! My phone has about 2

Gigabytes

of memory! Now this was in the late seventies, when Concorde had been flying for a good number of years.

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!! My phone has about 2

Gigabytes

of memory! Now this was in the late seventies, when Concorde had been flying for a good number of years.

My question, which is a bit of a tilt at windmills, is this; If you had to build Concorde all over again with the same airframe and engines, how much more room, how much lighter and how much more capable would the electronics be if they were made using the latest surface mount, Extremely High Density integrated circuits and microprocessors?

Thanks again everyone, for the best thread I have read on PPRuNe for two years (and there have been some superb ones in that time )

)

Roger.

Quote:

| The initial A/P+A/T 'Max Cruise' mod meant a major modification of the autothrottle computers. One of the circuit boards in particular was totally "butchered" on-site (Fairford), with well over a hundred track cuts and new wire links, not to mention the number of component changes (to give an idea to the 'experts', these were double-sided PCBs of about 15x20cm). |

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!! My phone has about 2

Gigabytes

of memory! Now this was in the late seventies, when Concorde had been flying for a good number of years.

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!! My phone has about 2

Gigabytes

of memory! Now this was in the late seventies, when Concorde had been flying for a good number of years.

My question, which is a bit of a tilt at windmills, is this; If you had to build Concorde all over again with the same airframe and engines, how much more room, how much lighter and how much more capable would the electronics be if they were made using the latest surface mount, Extremely High Density integrated circuits and microprocessors?

Thanks again everyone, for the best thread I have read on PPRuNe for two years (and there have been some superb ones in that time

)

)

Roger.

24th Aug 2010, 22:49

permalink Post: 101

ChristiaanJ

aaah yes, Max Climb/Max Cruise modes. I'd not forgotten this my friend, I was going to say a few words about that in a future post, but maybe we can do that now. (And I'd love to hear more of your comments on this here too, ChristiaanJ). The intake and autopilot modifications were in a way complimentary it's true, but really dealt with separate problems, at least in my view:

The intake control unit software change (a change to the control law that limited engine N1 as a function of intake local Mach number, Mo, and inlet total temperature, T1) was able to put an absolute limit on aircraft achievable Mach number during Mmo overshoots, but it would not PREVENT Mmo overshoots occurring altogether, it was more of a safety brake. This particular overspeed problem manifested itself well before route proving, and in fact the intake system 'fix' resulted in the Thrust Auto Reduce System being deleted, electronic control boxes and all. The TAR system was fitted on all development aircraft equiped with the digital intake system, and it tried (in vain) to limit extreme Mach overshoots. The production aircraft retained the TAR wiring and locked out circuit breakers, as well as two vacant spaces on the electronic racks. The prime reason for all these efforts were that some of the rapid excessive Mach overshoots quite often drove the intake into surge; the modification to this N1 limiter control enabled engine mass flow to be controlled in such a way that these surges could be prevented during temperature shears. The aircraft Mach limit was an extremely useful fringe benefit.

The AFCS mode change from what was Max Op and Max Op Soft (always loved that name) to Max Climb/Max Cruise was at a stroke able to deal with the regular Mmo overspeeds that kept on occuring during, as you say, the route proving trials of 1975, when British aircraft G-BOAC and the French aircrfraft F-BTSD carried out pre entry into service evaluation flights, SD sadly was the aircraft that was tragically lost at Gonez in July 2000). The Max Climb/Max Cruise AFCS mode combo is a mode like no other that I've personally seen before or since anywhere, (it for instance resulted an elsewhere taboo; an autopilot and an autothrotte working together IN A SPEED MODE).

This problem encountered primarily at lower lattitudes, (for example, G-BOAC doing route proving flights out of Singapore), occurring initially as the aircraft reached Mach 2. It was termed 'the insurmountable problem', but the AFCS designers (such as ChristiaanJ) fortunately did not have 'insurmountable problems' in their vocabulary. The issue was that the aircraft would have been climbing rapidly at Vmo of 530 KTS, with throttles at the gate as usual, At exactly 50,189' we hit what was known as 'the corner point' in the flight envelope, where 530 KTS IAS equated to Mach 2 exactly. Max Op mode would then 'let go' of the Vmo segment, and try and control the aircraft to Mach 2. (As the aircraft climbed, Vmo itself would progreesively decrease in order to equate to Mmo, or 2.04 Mach). But in very cold conditions, the aircraft still 'wanting' to accelerate, and the simple Max Op/Max Op Soft modes just could not cope with gentle pitch changes alone. The problem became even bigger during the cruise/climb when severe temperature shears occured, and routinely regular Mmo exceedences occured. Something had to be done, and something WAS done and how; enter Max Climb/Max Cruise. It was really a classic piece of design, where the aircraft would do the initial supersonic climb in Max Climb mode. This mode itself was relatively simple, in that it was more or less a Vmo -Vc hold mode. That meant that the difference at selection between indicated airspeed, Vc and Vmo would be maintained, with a vernier datum adjust to this being available. In practice this mode was selected pretty much at Vmo, so datum adjusting was not always required. Now comes the clever part; the autothrottle, this would operate in standy mode at this point, just waiting there doing nothing, with the throttles at maximum as before. So the aircraft would now climb as Vmo increased to 530 KTS, and then following a now constant Vmo of 530 KTS until the magic 'corner point' (51, 189' remember). Now all hell would break loose; the mode would automatically change to Max Cruise, the autothrottle would also be automaically selected to Mach Hold mode (initially datumed here to Mach 2) and the throttles would retard, attempting to hold this Mach 2 datum, and the autopilot is commands a 'fly up' signal, over a 20 second lag period to 600'/minute. Now comes an even cleverer (?) part; the autothrottle Mach Hold datum is gradually increased over a 100 second period towards Mach 2.02, and so in stable conditions the throttles would now gradually increase again until they once more reach the maximum limit. At this point, the autothrottles now come out of Mach Hold mode and back into the waiting in the wings standby mode. The autopilot would now cancel it's 600' fly up, demand, returning to a datum of Mach 2. There was a little more complexity built in also, where the difference between the 'commanded' and actual vertical speeds offset the autoplilot Mach 2 datum. This would apply whether the autothrottle had cut in (+600'/min demand) or with the throttles back at maximum (0'/minute demand. A positive climb error tweaked the cruise Mach up slightly, a negative error (eg. in a turn) the converse was true. The effect of all of this complexity was that the aircraft itself could 'scan' until it settled at a point where the throttles could be at maximum, and the speed between Mach 2 and 2.02. On the North Atlantic, with warmer ISA temperatures, there was usually just the initial routine with the autothrottle as you hit the corner point. However at lower lattitudes (eg. LHR BGI) there could be a few initial autothrottle intercepts before things settled down. This whole incredible routine completely took care of the insurmountable problem, a problem that was shown not only to be insurmountable, but was put to bed forever, by people like ChristiaanJ.

I hope that my explanation here does not sound too much like gibberish.

EXWOK

I think you've guessed right as far as my identity goes; it's great that it's not just Concorde pilots I can bore the socks off now

PS. I bet the ex-SEOs LOVED your comments

Dude

aaah yes, Max Climb/Max Cruise modes. I'd not forgotten this my friend, I was going to say a few words about that in a future post, but maybe we can do that now. (And I'd love to hear more of your comments on this here too, ChristiaanJ). The intake and autopilot modifications were in a way complimentary it's true, but really dealt with separate problems, at least in my view:

The intake control unit software change (a change to the control law that limited engine N1 as a function of intake local Mach number, Mo, and inlet total temperature, T1) was able to put an absolute limit on aircraft achievable Mach number during Mmo overshoots, but it would not PREVENT Mmo overshoots occurring altogether, it was more of a safety brake. This particular overspeed problem manifested itself well before route proving, and in fact the intake system 'fix' resulted in the Thrust Auto Reduce System being deleted, electronic control boxes and all. The TAR system was fitted on all development aircraft equiped with the digital intake system, and it tried (in vain) to limit extreme Mach overshoots. The production aircraft retained the TAR wiring and locked out circuit breakers, as well as two vacant spaces on the electronic racks. The prime reason for all these efforts were that some of the rapid excessive Mach overshoots quite often drove the intake into surge; the modification to this N1 limiter control enabled engine mass flow to be controlled in such a way that these surges could be prevented during temperature shears. The aircraft Mach limit was an extremely useful fringe benefit.

The AFCS mode change from what was Max Op and Max Op Soft (always loved that name) to Max Climb/Max Cruise was at a stroke able to deal with the regular Mmo overspeeds that kept on occuring during, as you say, the route proving trials of 1975, when British aircraft G-BOAC and the French aircrfraft F-BTSD carried out pre entry into service evaluation flights, SD sadly was the aircraft that was tragically lost at Gonez in July 2000). The Max Climb/Max Cruise AFCS mode combo is a mode like no other that I've personally seen before or since anywhere, (it for instance resulted an elsewhere taboo; an autopilot and an autothrotte working together IN A SPEED MODE).

This problem encountered primarily at lower lattitudes, (for example, G-BOAC doing route proving flights out of Singapore), occurring initially as the aircraft reached Mach 2. It was termed 'the insurmountable problem', but the AFCS designers (such as ChristiaanJ) fortunately did not have 'insurmountable problems' in their vocabulary. The issue was that the aircraft would have been climbing rapidly at Vmo of 530 KTS, with throttles at the gate as usual, At exactly 50,189' we hit what was known as 'the corner point' in the flight envelope, where 530 KTS IAS equated to Mach 2 exactly. Max Op mode would then 'let go' of the Vmo segment, and try and control the aircraft to Mach 2. (As the aircraft climbed, Vmo itself would progreesively decrease in order to equate to Mmo, or 2.04 Mach). But in very cold conditions, the aircraft still 'wanting' to accelerate, and the simple Max Op/Max Op Soft modes just could not cope with gentle pitch changes alone. The problem became even bigger during the cruise/climb when severe temperature shears occured, and routinely regular Mmo exceedences occured. Something had to be done, and something WAS done and how; enter Max Climb/Max Cruise. It was really a classic piece of design, where the aircraft would do the initial supersonic climb in Max Climb mode. This mode itself was relatively simple, in that it was more or less a Vmo -Vc hold mode. That meant that the difference at selection between indicated airspeed, Vc and Vmo would be maintained, with a vernier datum adjust to this being available. In practice this mode was selected pretty much at Vmo, so datum adjusting was not always required. Now comes the clever part; the autothrottle, this would operate in standy mode at this point, just waiting there doing nothing, with the throttles at maximum as before. So the aircraft would now climb as Vmo increased to 530 KTS, and then following a now constant Vmo of 530 KTS until the magic 'corner point' (51, 189' remember). Now all hell would break loose; the mode would automatically change to Max Cruise, the autothrottle would also be automaically selected to Mach Hold mode (initially datumed here to Mach 2) and the throttles would retard, attempting to hold this Mach 2 datum, and the autopilot is commands a 'fly up' signal, over a 20 second lag period to 600'/minute. Now comes an even cleverer (?) part; the autothrottle Mach Hold datum is gradually increased over a 100 second period towards Mach 2.02, and so in stable conditions the throttles would now gradually increase again until they once more reach the maximum limit. At this point, the autothrottles now come out of Mach Hold mode and back into the waiting in the wings standby mode. The autopilot would now cancel it's 600' fly up, demand, returning to a datum of Mach 2. There was a little more complexity built in also, where the difference between the 'commanded' and actual vertical speeds offset the autoplilot Mach 2 datum. This would apply whether the autothrottle had cut in (+600'/min demand) or with the throttles back at maximum (0'/minute demand. A positive climb error tweaked the cruise Mach up slightly, a negative error (eg. in a turn) the converse was true. The effect of all of this complexity was that the aircraft itself could 'scan' until it settled at a point where the throttles could be at maximum, and the speed between Mach 2 and 2.02. On the North Atlantic, with warmer ISA temperatures, there was usually just the initial routine with the autothrottle as you hit the corner point. However at lower lattitudes (eg. LHR BGI) there could be a few initial autothrottle intercepts before things settled down. This whole incredible routine completely took care of the insurmountable problem, a problem that was shown not only to be insurmountable, but was put to bed forever, by people like ChristiaanJ.

I hope that my explanation here does not sound too much like gibberish.

EXWOK

I think you've guessed right as far as my identity goes; it's great that it's not just Concorde pilots I can bore the socks off now

PS. I bet the ex-SEOs LOVED your comments

Dude

Last edited by M2dude; 25th Aug 2010 at 01:14 . Reason: missed out some info' (sorry)

24th Aug 2010, 23:00

permalink Post: 102

Quote:

|

Cut tracks and wire links were the 'staff of life' and the stuff of nightmare.

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!!

Our first minicomputers - to reconstruct the CT image - had 32

kilobytes

of memory on four boards, each about 17" square!!

|

You were already working with advanced stuff, Roger...

The notorious AICU (air intake control unit) had something like 2 kilo bit RAM, and 42 512- bit PROMs on 5 boards. That's a grand total of 2688 bytes of program storage, look-up tables, etc.

Quote:

| My question, which is a bit of a tilt at windmills, is this; If you had to build Concorde all over again with the same airframe and engines, how much more room, how much lighter and how much more capable would the electronics be if they were made using the latest surface mount, Extremely High Density integrated circuits and microprocessors? |

I can only make a stab in the dark, but ... I would say (mentally totting up all the electronics boxes and weighing them) the electronics fit weighed in the order of a couple of tons (maybe somebody has a closer figure?). So on an aircraft of 185T TOW, even if you could bring that down to a quarter of that weight, you'd gain less than 1%.

How much more capable?

Concorde did fine, so what more capability do you want ?

Seriously, you would have a glass cockpit, which would make nav etc. easier.

And of course you would be able to get rid of the flight engineer and his panel, so that would be a few more hundred kilos.... beer and all.

Where an electronics update would make a difference would be in the amount of aircraft wiring. In the olden days, every single signal had its own bit of wire... now everything passes via digital 'buses', where dozens of signals are transmitted over a single twisted pair.

For the computer and electronics buffs among you : it's the difference between the old Centronics printer interface, where every signal has its own wire, and todays USB.

CJ

24th Aug 2010, 23:33

permalink Post: 103

Landroger

Wow, that's a very interesting question, do you mind if I give it a tiny slant of my own, namely system distribution?

Concorde had an ENORMOUS number of electronic control boxes, for example the powerplant alone used TWENTY SIX rather heavy computers and control units, all of which used conventional 1970's manufacturing technology. (Although the intake box was a work of art; rows and rows of double sided PCBs completely crammed with TTL chips). This whole entourage literally weighed a ton, and could be easily replaced by four modern relatively light units with multiple redundancy built in). Even the AFCS used a total of sixteen heavy boxes, again these could be reduced to three, for a modern triple channel system. The three INUs and two ADCs (Very heavy units all) could be replaced with a single ADIRU and SAARU. To complete the package two FMCs (which would also furnish autothrottle functions) could be added. A massive weight saving could be made on the FBW system, by removing the bulky mechanical components (the feel and relay jacks as well as all the mechanical control runs and the massive mixing unit under the rear floor). Careful design could easily provide a full authority triplex or quadraplex FBW system. The current controls could be replaced with either an Airbus or Boeing type system, using either a sidestick (Airbus) or retain a conventional control column system (B777/787) using electric backdrive. The pilots can decide this one. A modern databus system would also be required for providing communication and redundancy; ARINC 629 would be MY preferred choice). The wholesale replacement of the various control units and computers, not to forget miles of wiring, as well as some bulky mechanical hardware would in my view save around 3 tonnes or more in weight alone. A now far more accurate control of aircraft systems would also bring major efficiency savings. As far as saving space, that possibly free up a couple of seat rows, if it were all done properly.

We can all dream I suppose

Dude

Quote:

| My question, which is a bit of a tilt at windmills, is this; If you had to build Concorde all over again with the same airframe and engines, how much more room, how much lighter and how much more capable would the electronics be if they were made using the latest surface mount, Extremely High Density integrated circuits and microprocessors? |

Concorde had an ENORMOUS number of electronic control boxes, for example the powerplant alone used TWENTY SIX rather heavy computers and control units, all of which used conventional 1970's manufacturing technology. (Although the intake box was a work of art; rows and rows of double sided PCBs completely crammed with TTL chips). This whole entourage literally weighed a ton, and could be easily replaced by four modern relatively light units with multiple redundancy built in). Even the AFCS used a total of sixteen heavy boxes, again these could be reduced to three, for a modern triple channel system. The three INUs and two ADCs (Very heavy units all) could be replaced with a single ADIRU and SAARU. To complete the package two FMCs (which would also furnish autothrottle functions) could be added. A massive weight saving could be made on the FBW system, by removing the bulky mechanical components (the feel and relay jacks as well as all the mechanical control runs and the massive mixing unit under the rear floor). Careful design could easily provide a full authority triplex or quadraplex FBW system. The current controls could be replaced with either an Airbus or Boeing type system, using either a sidestick (Airbus) or retain a conventional control column system (B777/787) using electric backdrive. The pilots can decide this one. A modern databus system would also be required for providing communication and redundancy; ARINC 629 would be MY preferred choice). The wholesale replacement of the various control units and computers, not to forget miles of wiring, as well as some bulky mechanical hardware would in my view save around 3 tonnes or more in weight alone. A now far more accurate control of aircraft systems would also bring major efficiency savings. As far as saving space, that possibly free up a couple of seat rows, if it were all done properly.

We can all dream I suppose

Dude

3rd Sep 2010, 19:58

permalink Post: 202

ChristiaanJ

During AUTOLAND a flare manoeuvre was instigated by the Pitch Computer at 50' radio, where a fairly simple flare law was invoked. I seem to remember that the law , which used a combination of radio rate (from the RadAlt) and vertical acceleration (from the INS) gave you a commanded height rate of 10'/second at 50', exponentially reducing to 1.7'/second at point of main wheel touch down.

The autoland on Concorde was both extremely accurate and reliable, and an awful lot of guys said they hated using it 'because it can land the aircraft better than I can'; their words NOT mine. (Personally I never bought that one, the guys were just modest as far as I was concerned

better than I can'; their words NOT mine. (Personally I never bought that one, the guys were just modest as far as I was concerned

). This in my opinion is an absolute testament to the AFCS designers; ChristiaanJ and his colleagues at SFENA and GEC Marconi.

). This in my opinion is an absolute testament to the AFCS designers; ChristiaanJ and his colleagues at SFENA and GEC Marconi.

To give the complete final approach story; as the aircraft tracked the glideslope in LAND mode, the autopilot G/S deviation, like most aircraft, was geared as an inverse function of radio altitude, and at 75' radio this deviation was flushed down the loo altogether, leaving the A/P to hold radio rate for just a few feet. At 50' the flare was instigated, and at around 35' DECRAB was commanded, where the yaw channel would use a rudder input alone to 'kick off drift' and align the aircraft with the runway centreline. (Concorde did not employ a fwd slip manoeuvre in crosswind conditions, being a slender delta). The 'final' command was at 15' radio, when the autothrottle smartly retarded the throttles. (The Pitch Computer flare law of course continuing to control decent rate all the way down). On touchdown the autopilot would be manually disengaged and the nose gently (usually ) lowered to the ground. (Concorde was only designed and certified as a CAT 3A system, so there was no automatic rollout guidance. However there was a runway guidance symbol on the ADI, which used a combination of Localiser deviation and lateral acceleration, to give you runway rollout track).

) lowered to the ground. (Concorde was only designed and certified as a CAT 3A system, so there was no automatic rollout guidance. However there was a runway guidance symbol on the ADI, which used a combination of Localiser deviation and lateral acceleration, to give you runway rollout track).

Now the flare law was tested every autoland, at G/S capture, and failure of this test resulted in the loss of LAND 3 status on the landing display panel. The most common defect of all with the Concorde autoland was in fact failure of the flare test, when at G/S capture, the previously illuminated LAND 3 indication would drop all of it's own to LAND 2. A simple changeover of autopilot paddle switches would nail the offending Pitch Computer, which would then be replaced before the next trip.

Dude

Quote:

| During landing, Concorde isn't flared at all, it is flown onto the ground at a constant pitch attitude. |

The autoland on Concorde was both extremely accurate and reliable, and an awful lot of guys said they hated using it 'because it can land the aircraft

better than I can'; their words NOT mine. (Personally I never bought that one, the guys were just modest as far as I was concerned

better than I can'; their words NOT mine. (Personally I never bought that one, the guys were just modest as far as I was concerned

). This in my opinion is an absolute testament to the AFCS designers; ChristiaanJ and his colleagues at SFENA and GEC Marconi.

). This in my opinion is an absolute testament to the AFCS designers; ChristiaanJ and his colleagues at SFENA and GEC Marconi.

To give the complete final approach story; as the aircraft tracked the glideslope in LAND mode, the autopilot G/S deviation, like most aircraft, was geared as an inverse function of radio altitude, and at 75' radio this deviation was flushed down the loo altogether, leaving the A/P to hold radio rate for just a few feet. At 50' the flare was instigated, and at around 35' DECRAB was commanded, where the yaw channel would use a rudder input alone to 'kick off drift' and align the aircraft with the runway centreline. (Concorde did not employ a fwd slip manoeuvre in crosswind conditions, being a slender delta). The 'final' command was at 15' radio, when the autothrottle smartly retarded the throttles. (The Pitch Computer flare law of course continuing to control decent rate all the way down). On touchdown the autopilot would be manually disengaged and the nose gently (usually

) lowered to the ground. (Concorde was only designed and certified as a CAT 3A system, so there was no automatic rollout guidance. However there was a runway guidance symbol on the ADI, which used a combination of Localiser deviation and lateral acceleration, to give you runway rollout track).

) lowered to the ground. (Concorde was only designed and certified as a CAT 3A system, so there was no automatic rollout guidance. However there was a runway guidance symbol on the ADI, which used a combination of Localiser deviation and lateral acceleration, to give you runway rollout track).

Now the flare law was tested every autoland, at G/S capture, and failure of this test resulted in the loss of LAND 3 status on the landing display panel. The most common defect of all with the Concorde autoland was in fact failure of the flare test, when at G/S capture, the previously illuminated LAND 3 indication would drop all of it's own to LAND 2. A simple changeover of autopilot paddle switches would nail the offending Pitch Computer, which would then be replaced before the next trip.

Dude

6th Sep 2010, 09:17

permalink Post: 222

Coffin Corner

Nick Thomas

Just like Christiaanj I'm trying to dig up an accurate flight envelope diagram. (A lot of my Concorde 'technical library' is out on long term loan), but I would suggest that anywhere within Concorde's published flight envelope you never hit any equivilant to Coffin Corner, a la' U2. The whole issue is really one of air DENSITY, rather that pressure, where as you climb at a given Mach Number, your Indicated airspeed (IAS) falls away with altitude. (Velocity of sound being primarily tied to static air temperature). Now if you are climbing in the stratosphere, where temperature is more or less constant up to around 65,000', you can say that your TRUE Airspeed (TAS) is also constant with climb at a given Mach number. But lift and drag are functions of IAS (the equivalent airspeed that the aircraft would 'feel' at sea level) and not TAS. Because the U2 had a very low Maximum allowable Mach number (Mmo) as IAS fell away with altitude, it would get to the point where it's lowest permitted airspeed (we called this VLA) got to within a few knots of Mmo and severe aerodynamic buffering. i.e. you were screwed with nowhere to go but down .

.

In the case of Concorde, Mach 2 at FL500 was 530KTS, falling to 430KTS at FL600. Although we have less lift due to 100KTS lower IAS, the aircraft is now much lighter (this is the whole principal of cruise/climb) which keeps the universe in balance, but drag is now significantly lower too, getting us better MPG .

.

On the ASI, the only limitation displayed was Vmo; however the Machmeter did display fwd and aft CG limits at a given Mach number. The ONLY time that Concorde would experience relatively low speeds at altitude was at Top of Descent. I'm a little fuzzy here how it all worked exactly (it's an age thing you know), I'm sure one of the pilots can correct me, but I seem to remember that the autothrottle was disconnected, ALTITUDE HOLD was selected on the AFCS, and the throttles slowly retarded. (If you pulled back too far you'd often get a gentle 'pop surge' from the engines, and you had also to be wary of equipment cooling airflow too). The aircraft was then allowed to gently decelerate, still at TOD altitude, until Mach 1.6, when power was tweaked to give 350KTS IAS and IAS HOLD was selected. The aircraft was now free to carry out her loooong descent to 'normal' altitudes. VLA on Concorde was not directly displayed as you never flew anywhere near it, and also every pilot knew his VLA . (Stray into this and you'd get a 'stick' shaker warning.

. (Stray into this and you'd get a 'stick' shaker warning.

I hope this blurb helps Nick

Dude

Just like Christiaanj I'm trying to dig up an accurate flight envelope diagram. (A lot of my Concorde 'technical library' is out on long term loan), but I would suggest that anywhere within Concorde's published flight envelope you never hit any equivilant to Coffin Corner, a la' U2. The whole issue is really one of air DENSITY, rather that pressure, where as you climb at a given Mach Number, your Indicated airspeed (IAS) falls away with altitude. (Velocity of sound being primarily tied to static air temperature). Now if you are climbing in the stratosphere, where temperature is more or less constant up to around 65,000', you can say that your TRUE Airspeed (TAS) is also constant with climb at a given Mach number. But lift and drag are functions of IAS (the equivalent airspeed that the aircraft would 'feel' at sea level) and not TAS. Because the U2 had a very low Maximum allowable Mach number (Mmo) as IAS fell away with altitude, it would get to the point where it's lowest permitted airspeed (we called this VLA) got to within a few knots of Mmo and severe aerodynamic buffering. i.e. you were screwed with nowhere to go but down

.

.

In the case of Concorde, Mach 2 at FL500 was 530KTS, falling to 430KTS at FL600. Although we have less lift due to 100KTS lower IAS, the aircraft is now much lighter (this is the whole principal of cruise/climb) which keeps the universe in balance, but drag is now significantly lower too, getting us better MPG

.

.

On the ASI, the only limitation displayed was Vmo; however the Machmeter did display fwd and aft CG limits at a given Mach number. The ONLY time that Concorde would experience relatively low speeds at altitude was at Top of Descent. I'm a little fuzzy here how it all worked exactly (it's an age thing you know), I'm sure one of the pilots can correct me, but I seem to remember that the autothrottle was disconnected, ALTITUDE HOLD was selected on the AFCS, and the throttles slowly retarded. (If you pulled back too far you'd often get a gentle 'pop surge' from the engines, and you had also to be wary of equipment cooling airflow too). The aircraft was then allowed to gently decelerate, still at TOD altitude, until Mach 1.6, when power was tweaked to give 350KTS IAS and IAS HOLD was selected. The aircraft was now free to carry out her loooong descent to 'normal' altitudes. VLA on Concorde was not directly displayed as you never flew anywhere near it, and also every pilot knew his VLA

. (Stray into this and you'd get a 'stick' shaker warning.

. (Stray into this and you'd get a 'stick' shaker warning.

I hope this blurb helps Nick

Dude

7th Sep 2010, 15:34

permalink Post: 261

Brit312

---- that reminds me....

On the two prototypes, the AFCS controller was located on the centre pedestal, and had two big rotary multiposition switches to select the autopilot/flight director modes, plus the autopilot, flight director and autothrottle engage switches.

On the preproduction and production aircraft, the design was totally changed and became the big box with rows of pushbuttons and little handwheels, to set things like altitude and speed, that one now sees at the top centre of the instrument panel, just under the windscreen and above the engine instruments.

It was not until years and years later that I had an occasion to visit a VC-10 cockpit .... to discover how similar the VC-10 AFCS controller was to the prototype Concorde one.

No wonder... both were made by Elliott.

CJ

On the two prototypes, the AFCS controller was located on the centre pedestal, and had two big rotary multiposition switches to select the autopilot/flight director modes, plus the autopilot, flight director and autothrottle engage switches.

On the preproduction and production aircraft, the design was totally changed and became the big box with rows of pushbuttons and little handwheels, to set things like altitude and speed, that one now sees at the top centre of the instrument panel, just under the windscreen and above the engine instruments.

It was not until years and years later that I had an occasion to visit a VC-10 cockpit .... to discover how similar the VC-10 AFCS controller was to the prototype Concorde one.

No wonder... both were made by Elliott.

CJ

9th Sep 2010, 00:09

permalink Post: 286

Quote:

| I cannot think of a civil airliner where the nose gear retracts backwards - they all retract forwards. |

A small handpump is used to ensure downlock after freefall extension. (The Dash 8 and Fokker 50 have - much larger and draggier - backwards retracting main gear, assisted by handpump and springloading respectively for downlock after emergency freefall extension.)

A small handpump is used to ensure downlock after freefall extension. (The Dash 8 and Fokker 50 have - much larger and draggier - backwards retracting main gear, assisted by handpump and springloading respectively for downlock after emergency freefall extension.)

Thanks to all Concorde experts for this truly wonderful thread. The ingenuity of design and the complexity of design that enabled the technological marvel that is Concorde never cease to amaze this humble airline driver. Having missed the opportunity to fly on Concorde is high on my list of aviatic regrets as well, and I'll have to make do with the memories of watching Air France Concordes taking off from CDG during our turnarounds there.

I could (and actually have) spent hours following this thread.

Is it true that Concorde was always flown by the highest seniority BA captains, copilots and flight engineers? Would Concorde usually be the last rung on the ladder before retirement for Captains/FEs or was it usual to return to slower equipment after a stint on Concorde?

And, sorry if I missed this, would Concorde thrust levers move during autothrottle operation?

Lastly, Concorde was originally to have had a large moving map system. Any insights into why and how that got scrapped along the way?

Thanks!

9th Sep 2010, 07:51

permalink Post: 289

Alpine Flyer

And a darned good airplane too

One for my 'winged' friends really, but with BA it was an issue of seniority, with a long waiting list for selection. As far as I recall there were only ever a couple of cases when a captain left the fleet for another aircraft, most would very happily fly Concorde until retirement at 55. The senior first officers generally had to (reluctantly) change fleets when they got their commands, however there was as far as I remember two exceptions here, where an SFO was able to 'jump seats' to captain. SEOs would stay on Concorde until retirement. (In all the years that I can remember there was only one case of an

SEO

switching fleets from Concorde). A pilot friend once put it to me that if your passion in life was as a flyer of aeroplanes, then there was really nowhere to go after Concorde.

Oh yes, Concorde had a 'real' full flight flight regime autothrottle. The autothrottle actuator would drive all four levers together via individual isolation clutches and the computer used the sum of all four lever angles. In the unlikely event of an engine being shut down in flight, the A/T could still be used. There was an isolation switch on the roof panel that would enable the affected engine's thrust lever to be isolated and closed to idle, the computer using the sigmals from the other three engines, demanding a now higher lever angle to compensate for the failed engine.

The prototypes I recall had a DECCA moving map, but with the availability of INS (and the decline and finally shutting down of the DECCA chains) made the system a waste of time (not to mention space).

Dude

Quote:

| Well, the deHavilland Dash 7 has one, and I will take exception to anyone denying it airliner status. |

Quote:

| Is it true that Concorde was always flown by the highest seniority BA captains, copilots and flight engineers? Would Concorde usually be the last rung on the ladder before retirement for Captains/FEs or was it usual to return to slower equipment after a stint on Concorde? |

Quote:

| And, sorry if I missed this, would Concorde thrust levers move during autothrottle operation? |

Quote:

| Lastly, Concorde was originally to have had a large moving map system. Any insights into why and how that got scrapped along the way? |

Dude

13th Sep 2010, 01:18

permalink Post: 336

spfoster

Hi again Steve. At FL600 your aircraft is going to be relatively light, and your autopilot is set to ALT HOLD mode. As the aircraft continues to burn fuel it will 'try' and climb, but the ALT HOLD mode will of course slightly reduce pitch attitude to keep prevent the aircraft from climbing. The autothrottle in MACH HOLD mode can keep us from straying from Mach 2, large positive temperature shears were to my knowledge almost unheard of, and so any speed reduction was exceedingly unlikely. We really need a pilot's input here to further clarify the realities of LHR-BGI supersonic cruise; that's the way the AFCS was designed to do things however.

Dude

Quote:

|

I never knew you couldn't prime ALT ACQ from MAX CLIMB / MAX CRUISE. I was thinking though that if you had ALT HOLD selected then the autopilot wouldn't be able to vary the pitch attitude and it would hold at the ALT HOLD level. Once there it wouldn't be able to use pitch to increase or decrease speed if necessary. I can see how the autothrottles could hold the speed back but if it were to get warmer then even at full power it may not be able to maintain speed at a fixed altitude.

I'm sure there is a simple answer which will leave us saying "oh yeah, how obvious, didn't think of that"  Just strange it doesn't seem to be written anywhere.

Just strange it doesn't seem to be written anywhere.

|

Dude

30th Oct 2010, 12:46

permalink Post: 642

Fuel Saving Landing

Requirements :

Not permitted with :

Notes

3-engine landings were permitted. For all landings the landing gear would be lowered earlier than normal to ensure the brakes were stone cold to start with, maximum reverse thrust would be used on landing, and braking modulated so as to use (nearly) all of the full length of the runway. Landing performance figures at 130,000 kgs were in the performance manual for most runways. Any runway for which this procedure had not been pre-authorised required some rather tedious calculations, using the generalised basic data and graphs found in the performance manual.

If manual performance calculations were necessary, the F/E and I usually seemed to find that another problem that required our urgent and undivided attention had come up, and we would reluctantly be compelled to hand over all the manuals, charts and graphs for the F/O to perform the calculations!

If the aircraft had an AFT ZFW CG (perhaps loaded with a lot of heavy bags in the rear hold), and given the specific fuel distribution requirements for a fuel saving landing, it was possible that the landing weight might have to be reduced below 130,000 kgs, in order to achieve a landing CG of 53.5%.

After landing, record the actual landing weight in the Maintenance Log using code 2899XXOO, sign it, and then leg it swiftly, to avoid M2Dude and the boys, who somehow always managed to imply that you were responsible for anything that had gone wrong with their pride and joy since they last handed her over to you!

Reasons

The clue is in the name! A possible saving of roughly 5,200 gallons of fuel, nearly 19,000 kgs, which need not be jettisoned, thus reducing the time spent in the air before re-landing, fuel costs and pollution.

Best Regards

Bellerophon

Requirements :

- Manual landing, at V REF , only

- Minimum of one autothrottle operative at start of approach

- Contingency power available

- Specific fuel distribution achieved

- Record in Maintenance Log

Not permitted with :

- Slippery runway

- Precipitation covered runway

- 3-engine ferry

- 2-engine approach and landing

- Reduced noise approach

- Fuelled with wide-cut fuel

- Secondary nozzle locked out

- Brake unit isolated

- Total loss of Electric Trim

- Total loss of Pitch Stab

- Total loss of Electrical Signalling

- Suspected tyre failure

Notes

3-engine landings were permitted. For all landings the landing gear would be lowered earlier than normal to ensure the brakes were stone cold to start with, maximum reverse thrust would be used on landing, and braking modulated so as to use (nearly) all of the full length of the runway. Landing performance figures at 130,000 kgs were in the performance manual for most runways. Any runway for which this procedure had not been pre-authorised required some rather tedious calculations, using the generalised basic data and graphs found in the performance manual.

If manual performance calculations were necessary, the F/E and I usually seemed to find that another problem that required our urgent and undivided attention had come up, and we would reluctantly be compelled to hand over all the manuals, charts and graphs for the F/O to perform the calculations!

If the aircraft had an AFT ZFW CG (perhaps loaded with a lot of heavy bags in the rear hold), and given the specific fuel distribution requirements for a fuel saving landing, it was possible that the landing weight might have to be reduced below 130,000 kgs, in order to achieve a landing CG of 53.5%.

After landing, record the actual landing weight in the Maintenance Log using code 2899XXOO, sign it, and then leg it swiftly, to avoid M2Dude and the boys, who somehow always managed to imply that you were responsible for anything that had gone wrong with their pride and joy since they last handed her over to you!

Reasons

The clue is in the name! A possible saving of roughly 5,200 gallons of fuel, nearly 19,000 kgs, which need not be jettisoned, thus reducing the time spent in the air before re-landing, fuel costs and pollution.

Best Regards

Bellerophon

3rd Dec 2010, 13:37

permalink Post: 829

M2Dude

There was an unconfirmed report - so no doubt completely baseless - that ...er...another operator... noticed a rather unusual but highly favourable wind component on a JFK...er...Easterly... crossing, as they passed through FL520 or so, giving them a magnificent groundspeed.

Deciding that they would like to maintain this groundspeed, they went ALT HOLD and MACH HOLD at around FL530. They maintained their groundspeed, so the story goes, but the autothrottle then progressively reduced the N1, as the aircraft weight reduced, over the next couple of hours, into the prohibited range!

Did you ever hear of any such event?

Best Regards

Bellerophon

Quote:

| the dodgy sustained N1 band for the Olympus 593, this was 88-91% N1. This figure was never an issue in service as at cruise...the N1 was always run at the flat rate limit of 101.5%. Below ISA -7 the intake system would progressively reduce N1...falling to 97.4% at ISA -24 |

Deciding that they would like to maintain this groundspeed, they went ALT HOLD and MACH HOLD at around FL530. They maintained their groundspeed, so the story goes, but the autothrottle then progressively reduced the N1, as the aircraft weight reduced, over the next couple of hours, into the prohibited range!

Did you ever hear of any such event?

Best Regards

Bellerophon

4th Dec 2010, 09:17

permalink Post: 832

Bellerophon

Ahhh this 'other operator' (I'd quite forgotten our code for *** ******). And as for this obviously baseless story

.... er yes it did happen. I should really have qualified my post and said 'The controlled N1

as long as the aeroplane was operated

CORRECTLY

was always at least in the upper 90's, well away from our blade resonance area'. I don't quite recall after the engines were removed post-flight (At Rolls-Royce's insistance) whether the entire LP compressor sections or just the first few stages had to be replaced at the engine overhaul base. In either case it was a rather expensive piece of experimentation.

.... er yes it did happen. I should really have qualified my post and said 'The controlled N1

as long as the aeroplane was operated

CORRECTLY

was always at least in the upper 90's, well away from our blade resonance area'. I don't quite recall after the engines were removed post-flight (At Rolls-Royce's insistance) whether the entire LP compressor sections or just the first few stages had to be replaced at the engine overhaul base. In either case it was a rather expensive piece of experimentation.

ChristiaanJ

Certainly my friend (but hey, remember that I'm an old Volts and Amps and Ohms ancient at heart too

).

).

The lighting of a reheat flame can be achieved in three ways:

1) By using an electric arc ignitor.. the least reliable system, although relatively simple in concept.

2) Catalytic ignition, where the reheat fuel is sprayed over a platinum based catalyst, spontaneously igniting. I recall that although generally reliable, eventually the catalyst compound erodes away and you are left with no ignition source.

3) Hot streak injection (or ignition). I this case a sizable jet of fuel is injected through a single injector placed the the combustion chamber of the engine, a powerful streak of flame then 'shoots out' of the turbine, and ignites the reheat fuel. Generally reliable as long as the injector itself does not carbon up (as our new friend Howiehowie93 pointed out). What amazed me with this system when we were looking at it for Concorde, was that the Olympus 593 designer I spoke to at Rolls-Royce told me that it has a negligible effect on turbine blade life, as the hottest part of the flame does not hit the blades themselves, and also of course it is a very short duration burn anyway (1 - 2 seconds).

And Christian my friend, you should indeed 'rabbit on' here about some of your observations regarding Concorde electronics technology, you have a unique insight here as (probably) the only Concorde systems designer that regularly visits 'here'. I'm sure I speak for many of us here when I say that your experiences are unique and your contributaions are always illuminating. Come on, let's have some Volts/Amps and Ohms

Best Regards

Dude

Quote:

| Deciding that they would like to maintain this groundspeed, they went ALT HOLD and MACH HOLD at around FL530. They maintained their groundspeed, so the story goes, but the autothrottle then progressively reduced the N1, as the aircraft weight reduced, over the next couple of hours, into the prohibited range!Did you ever hear of any such event? |

.... er yes it did happen. I should really have qualified my post and said 'The controlled N1

as long as the aeroplane was operated

CORRECTLY

was always at least in the upper 90's, well away from our blade resonance area'. I don't quite recall after the engines were removed post-flight (At Rolls-Royce's insistance) whether the entire LP compressor sections or just the first few stages had to be replaced at the engine overhaul base. In either case it was a rather expensive piece of experimentation.

.... er yes it did happen. I should really have qualified my post and said 'The controlled N1

as long as the aeroplane was operated

CORRECTLY

was always at least in the upper 90's, well away from our blade resonance area'. I don't quite recall after the engines were removed post-flight (At Rolls-Royce's insistance) whether the entire LP compressor sections or just the first few stages had to be replaced at the engine overhaul base. In either case it was a rather expensive piece of experimentation.

ChristiaanJ

Quote:

| Can somebody explain to a "Volts and Amps and Ohms ancient" what "hotstreak injection" is/was (without getting scabrous)? |

).

).

The lighting of a reheat flame can be achieved in three ways:

1) By using an electric arc ignitor.. the least reliable system, although relatively simple in concept.

2) Catalytic ignition, where the reheat fuel is sprayed over a platinum based catalyst, spontaneously igniting. I recall that although generally reliable, eventually the catalyst compound erodes away and you are left with no ignition source.

3) Hot streak injection (or ignition). I this case a sizable jet of fuel is injected through a single injector placed the the combustion chamber of the engine, a powerful streak of flame then 'shoots out' of the turbine, and ignites the reheat fuel. Generally reliable as long as the injector itself does not carbon up (as our new friend Howiehowie93 pointed out). What amazed me with this system when we were looking at it for Concorde, was that the Olympus 593 designer I spoke to at Rolls-Royce told me that it has a negligible effect on turbine blade life, as the hottest part of the flame does not hit the blades themselves, and also of course it is a very short duration burn anyway (1 - 2 seconds).

And Christian my friend, you should indeed 'rabbit on' here about some of your observations regarding Concorde electronics technology, you have a unique insight here as (probably) the only Concorde systems designer that regularly visits 'here'. I'm sure I speak for many of us here when I say that your experiences are unique and your contributaions are always illuminating. Come on, let's have some Volts/Amps and Ohms

Best Regards

Dude

21st Dec 2010, 11:13

permalink Post: 911

PBL

As far as the Autothrottle side of things (you know, the throttles actually MOVING in response to autothrottle action, how novel

), that was designed by the Elliot part of the Anglo-French AFCS consortium. (This then became Marconi-Elliot, and then GEC-Marconi, and finally part of BAe Systems). I doubt very much if this is in anyway connected with Airbus at all. (I know,...Duh!!).

), that was designed by the Elliot part of the Anglo-French AFCS consortium. (This then became Marconi-Elliot, and then GEC-Marconi, and finally part of BAe Systems). I doubt very much if this is in anyway connected with Airbus at all. (I know,...Duh!!).

As far as the Concorde engine power control philosophy, well this was Rolls-Royce, through and through, with some BAe input, so again I think you can rule that out too.

Basically PBL, I would say that in answer to your question, we can say that they were definately not, thank goodness ... (Naughty boy, Dude

... (Naughty boy, Dude

). Bearing in mind of course that the current Airbus philosophy can be traced back to the early A320s.... not a Roller in sight there.

). Bearing in mind of course that the current Airbus philosophy can be traced back to the early A320s.... not a Roller in sight there.

Best Regards

Dude

Quote:

| And how do we know they weren't designed by the very same people? |

), that was designed by the Elliot part of the Anglo-French AFCS consortium. (This then became Marconi-Elliot, and then GEC-Marconi, and finally part of BAe Systems). I doubt very much if this is in anyway connected with Airbus at all. (I know,...Duh!!).

), that was designed by the Elliot part of the Anglo-French AFCS consortium. (This then became Marconi-Elliot, and then GEC-Marconi, and finally part of BAe Systems). I doubt very much if this is in anyway connected with Airbus at all. (I know,...Duh!!).

As far as the Concorde engine power control philosophy, well this was Rolls-Royce, through and through, with some BAe input, so again I think you can rule that out too.

Basically PBL, I would say that in answer to your question, we can say that they were definately not, thank goodness

... (Naughty boy, Dude

... (Naughty boy, Dude

). Bearing in mind of course that the current Airbus philosophy can be traced back to the early A320s.... not a Roller in sight there.

). Bearing in mind of course that the current Airbus philosophy can be traced back to the early A320s.... not a Roller in sight there.

Best Regards

Dude

Last edited by M2dude; 21st Dec 2010 at 11:36 . Reason: My crap spelling

21st Dec 2010, 13:04

permalink Post: 922

quote:Rolls Royce did some analysis on the flight, and were amazed at how well the propulsion systems coped with some of the temperature sheers that we encountered, sometimes 4 to 5 deg's/second. They said that the prototype AFCS had been defeated by rises of only 0.25 deg's/second ).unquote

Just for the record, the intake control system was designed to cope with a temperature shear of 21 deg C in one mile (about 3 seconds)

quote:Not meaning to go off onto a (yet another) tangent; Negative temperature shears, very common at lower lattidudes, always plagued the development aircraft; you would suddenly accelerate, and in the case of a severe shear, would accelerate and accelerate!! (Your Mach number, quite naturaly, suddenly increased with the falling temperature of course, but because of the powerplant suddenly hitting an area of hyper-efficiencey, the A/C would physically accelerate rapidly, way beyond Mmo). Many modifications were tried to mitigate the effects of severe shears, in the end a clever change to the intake control unit software fixed it. (Thanks to this change the production series A/C would not be capable of level flight Mach numbers of any more than Mach 2.13, remembering that Mmo was set at 2.04).unquote

Not temperature shears, and not AICU modifications (which I see has been discussed in a later posting). But back to the 'shears':

Most of Concorde's flight testing was, naturally, done out of Toulouse and Fairford, i.e. into moderate latitude atmospheres where the tropopause is normally around 36,000 ft so that the supersonic flight testing was done in atmosphers where the temperature doesn't vary with altitude. The autopilot working in Mach hold would see an increase in Mach and apply up elevator to reduce IAS and recover the macg setting. But at the lower latitudes around the equator the atmosphere is different in its large scale characteristics. In particular the tropopause is much, much higher and can get as high as 55,000 ft. Nobody had been up there to see what it was like! Now when the A/P applied up elevator to reduce IAS it went into a region of colder air. But the speed of sound is proportional to air temperature, so as the aircraft ascended the IAS dropped alright but since the ballistic (true) velocity of the aircraft takes a while to change and since the speed of sound had dropped the Mach number was increased, so the A/P seeing this applied more up elevator and the aircraft went up and the speed of sound dropped and ........

Like solving crossword clues, the answer is obvious once you have spent some time finding it!

This phenomenon rather than temperature shears (encountered mainly over the tops of Cb clouds) was the reason for the autopilot modifications which included that clever use of autothrottle (I can use that adjective since it was my French colleagues that devised it)

And before anyone asks; yes, the same problem would relate to subsonic aircraft operating in Mach hold driven by the elevators and flying below the tropopause, but:

a) Subsonic aircraft are old ladies by comparison with Concorde in that they fly at only half the speed. At Concorde velocities even modest changes in pitch attitude can generate some pretty impressive rates of climb or dive!

b) Subsonic aircraft are normally constrained by ATC to fly at fixed flight levels - the use of elevator to control Mach number is not really an option - you have to use an autothrottle.

There was that other problem, also described in later postings, where the aircraft regularly 'rang the bell' when passing through the Vmo/Mmo corner in the lower latitudes, but this was simply due to the additional performance one got in these ISA minus conditions in comparison to the temperatures encountered around the same corner in higher temperatures.

Anyway, the flight test campaign got me my first sight of sunrise over the Arabian desert and my first trip to Asia, so it goes into my Concorde memory bank.

Just for the record, the intake control system was designed to cope with a temperature shear of 21 deg C in one mile (about 3 seconds)

quote:Not meaning to go off onto a (yet another) tangent; Negative temperature shears, very common at lower lattidudes, always plagued the development aircraft; you would suddenly accelerate, and in the case of a severe shear, would accelerate and accelerate!! (Your Mach number, quite naturaly, suddenly increased with the falling temperature of course, but because of the powerplant suddenly hitting an area of hyper-efficiencey, the A/C would physically accelerate rapidly, way beyond Mmo). Many modifications were tried to mitigate the effects of severe shears, in the end a clever change to the intake control unit software fixed it. (Thanks to this change the production series A/C would not be capable of level flight Mach numbers of any more than Mach 2.13, remembering that Mmo was set at 2.04).unquote

Not temperature shears, and not AICU modifications (which I see has been discussed in a later posting). But back to the 'shears':

Most of Concorde's flight testing was, naturally, done out of Toulouse and Fairford, i.e. into moderate latitude atmospheres where the tropopause is normally around 36,000 ft so that the supersonic flight testing was done in atmosphers where the temperature doesn't vary with altitude. The autopilot working in Mach hold would see an increase in Mach and apply up elevator to reduce IAS and recover the macg setting. But at the lower latitudes around the equator the atmosphere is different in its large scale characteristics. In particular the tropopause is much, much higher and can get as high as 55,000 ft. Nobody had been up there to see what it was like! Now when the A/P applied up elevator to reduce IAS it went into a region of colder air. But the speed of sound is proportional to air temperature, so as the aircraft ascended the IAS dropped alright but since the ballistic (true) velocity of the aircraft takes a while to change and since the speed of sound had dropped the Mach number was increased, so the A/P seeing this applied more up elevator and the aircraft went up and the speed of sound dropped and ........

Like solving crossword clues, the answer is obvious once you have spent some time finding it!

This phenomenon rather than temperature shears (encountered mainly over the tops of Cb clouds) was the reason for the autopilot modifications which included that clever use of autothrottle (I can use that adjective since it was my French colleagues that devised it)

And before anyone asks; yes, the same problem would relate to subsonic aircraft operating in Mach hold driven by the elevators and flying below the tropopause, but:

a) Subsonic aircraft are old ladies by comparison with Concorde in that they fly at only half the speed. At Concorde velocities even modest changes in pitch attitude can generate some pretty impressive rates of climb or dive!

b) Subsonic aircraft are normally constrained by ATC to fly at fixed flight levels - the use of elevator to control Mach number is not really an option - you have to use an autothrottle.

There was that other problem, also described in later postings, where the aircraft regularly 'rang the bell' when passing through the Vmo/Mmo corner in the lower latitudes, but this was simply due to the additional performance one got in these ISA minus conditions in comparison to the temperatures encountered around the same corner in higher temperatures.

Anyway, the flight test campaign got me my first sight of sunrise over the Arabian desert and my first trip to Asia, so it goes into my Concorde memory bank.

7th Jan 2011, 13:13

permalink Post: 1079

The thar intakes

Clive & Christian

Gentlemen, I think you will find that 102 did indeed have a totally 'unique' analog intake control system. Not only were the RDCUs (not AICUs in this case chaps) totally different, there were major architectural changes over the prototype system too. Also, although the basic intake structure was the same as 101 and all subsequent aircraft, there was still the prototype approach to local pressure sensing adapted, ie. Intake face total pressure P∞ sensed directly via the infamous 'magic holes' rather than using digitally synthesised values based on mainline aircraft manometric probe, total (pitot)pressure. As 101's intakes only went 'live' in mid-march 1973, I assumed that maybe they (AS) wanted an operative intake system from the outset on 102 when it first flew in January of that year. What puzzled me was why they went for this seemingly enhanced (and expensive) analog system on 102 and not the original system. (As 102 used a production type intake, I guess that they would have to have at least made some changes to the control system ; there was no exotic double hinged 'Dump Door', but the far simpler and elegant 'Spill Door' with integral Aux' Inlet Vane that was known and loved by us all). Rumour had it that AS still wanted to pursue the 'magic holes' solution and were dead against the decision to go digital. (This particular decision was taken in October 1970, which makes the 102 AICS route seem all the more strange).

And ChristiaanJ; what you guys achieved with the MAX CLIMB/MAX CRUISE was nothing short of remarkable. Just about the most exotic (and complex) autopilot mode that I've ever seen, that solved so MANY problems. (Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

(Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

).

).

Best regards

Dude

Gentlemen, I think you will find that 102 did indeed have a totally 'unique' analog intake control system. Not only were the RDCUs (not AICUs in this case chaps) totally different, there were major architectural changes over the prototype system too. Also, although the basic intake structure was the same as 101 and all subsequent aircraft, there was still the prototype approach to local pressure sensing adapted, ie. Intake face total pressure P∞ sensed directly via the infamous 'magic holes' rather than using digitally synthesised values based on mainline aircraft manometric probe, total (pitot)pressure. As 101's intakes only went 'live' in mid-march 1973, I assumed that maybe they (AS) wanted an operative intake system from the outset on 102 when it first flew in January of that year. What puzzled me was why they went for this seemingly enhanced (and expensive) analog system on 102 and not the original system. (As 102 used a production type intake, I guess that they would have to have at least made some changes to the control system ; there was no exotic double hinged 'Dump Door', but the far simpler and elegant 'Spill Door' with integral Aux' Inlet Vane that was known and loved by us all). Rumour had it that AS still wanted to pursue the 'magic holes' solution and were dead against the decision to go digital. (This particular decision was taken in October 1970, which makes the 102 AICS route seem all the more strange).

And ChristiaanJ; what you guys achieved with the MAX CLIMB/MAX CRUISE was nothing short of remarkable. Just about the most exotic (and complex) autopilot mode that I've ever seen, that solved so MANY problems.

(Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

(Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

).

).

Best regards

Dude

Last edited by M2dude; 8th Jan 2011 at 09:58 . Reason: 'All I want for Christmas is the ability to spell'

12th Jan 2011, 20:45

permalink Post: 1081

Wow, what a great thread! I started reading it yesterday and am up to page 19 so far! I flew on the wonderful white bird once, in 1999, a Manchester - round the bay at Mach 2 - Paris flight in G-BOAD. And the wonderful thing was I did the entire flight, push back at Manchester to parking at Paris, in the jump seat! What a fabulous experience - thank you Roger!

Here's a picture I took as the aircraft turne left towards the French coast:

One memory is climbing through 50,000 feet over South Wales before turning down the Bristol Channel. It was glorious August day and I had a great view forward past the captain and particularly out of the left window. The speed over the ground at Mach 0.95 seemed noticably faster than a subsonic jet, and that view was breathtaking! The Bristol Channel was edged in golden yellow beaches, and I could see right across south west England to the English Channel. In my headset the controller called another aircraft; "Speedbird 123 if you look up now you will see you are about to be overflown by Concorde". I leaned towards my side window and there was Speedbird 123, a tiny scurrying beetle miles below us. From this height the fair-weather cu looked as if they were on the ground - like small white splodges from some celestial artist's paint brush.

We cruised at Mach 2 and 60,000' over the Bay for a while and the pax came forward to view the flightdeck. I was amazed how patient was the supernumery captain who was answering the same questions over and over again was (the flight crew were too busy to chat).

The approach to CDG looked far steeper than other airliner approaches I had witnessed from the flight deck; more like one of my glide approaches in the Chipmunk! But it wasn't, of course, as we were following the 3 degree glideslope. I guess it was an illusion brought about by the steep pitch angle.

I remember the captain resting his hands on the throttles as they shuttled back and forth under autothrottle control, the smooth touchdown, the 'landing' of the nosewheel followed by full forward stick, and thinking "we'll never make that turn off". Then on came the powerful reverse and the brakes, I was thrust foreward in my harness, the speed disappeared, and we made the turnoff easily!

Oh, and that stange bouncy ride in the flight deck on the ground as the long nose forward of the nosewheel flexed over every joint in the taxyway. So bad at times it was difficult to take a photograph!

What an experience!

I have a question which I hope hasn't been answered in the pages (20 to this one) that I've yet to read.

From an earlier post I understand that the anti-skid used a rotational reference from the unbraked nosewheels to compare to the rotation of the mains, and that with gear down in the air a substiute nose-wheel referance is supplied which, because the mains are not yet rotating, allows the anti-skid to keep the brakes off.

But what happens when the mains touch down with the nosewheels still high in the air? What (if anything) inhibits wheel braking until the nosewhels are on the ground (and therefore rotating)?

Also, this thread started with a question about the lack of an APU. When Concorde was parked could the aircon and cabin lighting be powered by external electrical power, or did the cabin aircon without engine power require an external 'aircon unit' to be connected? Or was aircon simply not available without at least one engine running?

And one for Landlady or any other CC. If a table top was set up between the cabins during service, how did the 'front' crew service the first 2 rows of the rear cabin?

Being 'up front' for my entire flight, I missed out on the cabin service. But superb though I'm sure that was, under the circumstances it's not something I regret!

Here's a picture I took as the aircraft turne left towards the French coast: