17th Aug 2010, 10:50

permalink Post: 16

Hi Christiaan, yes THAT was the MEPU (Good photo of G-BBDG by the way). As far as fitting an APU in the tail cone, I still personally think that UNLESS you are prepared to pass a sizable pneumatic duct

through a fuel tank

, (Remember that tank 11 occupied the entire rear fuselage between the rear cargo aft wall and the front of the tail cone). then I don't think that this was really on. (It's quite possible of course that I'm missing something here, it comes with age

).

).

As far as the MEPU goes, all it really did was drive 2 hydraulic pumps; the Green System then powering the 40 KVA emergency generator; unless you are going to use the APU for engine starting and ground air conditioning, then I honestly don't think that there would be much point. It's interesting also to note that the MPU, being a rocket motor, needed no air intake, and as it was not driving any huge loads, the exhaust duct dould be quite narrow.

).

).

As far as the MEPU goes, all it really did was drive 2 hydraulic pumps; the Green System then powering the 40 KVA emergency generator; unless you are going to use the APU for engine starting and ground air conditioning, then I honestly don't think that there would be much point. It's interesting also to note that the MPU, being a rocket motor, needed no air intake, and as it was not driving any huge loads, the exhaust duct dould be quite narrow.

27th Aug 2010, 22:12

permalink Post: 145

Notfred

Love the lightning story, hadn't heard that one before.

That would have been production series test aircraft G-BBDG, A/C 202 before a purpose built hangar (more shed really) was built to house her, with fin and U/C removed. This aircraft has now been beautifully restored at Brooklands museum.

You are quite correct about the pushback, not having an APU (THAT story again

) meant that a one engine in each nacelle pair had to be started on the gate, and the other in each nacelle started after push. Having a symetrical pair started enabled all 3 hydraulic systems, and hence most of the critical systems to be checked puring pushback.

) meant that a one engine in each nacelle pair had to be started on the gate, and the other in each nacelle started after push. Having a symetrical pair started enabled all 3 hydraulic systems, and hence most of the critical systems to be checked puring pushback.

Brake temperatures always had to be monitored; they really could get very hot. If a wheel was still too warm after T/O, then the gear would be left down just a little longer to aid cooling. (Each brake also had an electric cooling fan).

Idle thrust was always a problem in that it was too high; there was a 'lo idle' setting, but depending on the temperature of the day the difference was not that big. You could not just reduce idle some more because of a malady known as rotating stall. This can plague any engine, but the Olympus 593 was particularly susceptible. At very low idle speeds, pockets of air 'rotate' around the first few compressor stages and can completely alter the airflows through the engine. It is important that the engine is always accelerated quickly through this zone on start-up, because serious damage can occur if the engine runs for any period of time in the rotating stall region. If the engine DOES operate in this zone, then the combustion process can even occur in the last few stages of the HP compressor, causing extreme damage. This damage, although malignant, can result in blade failure and the subsequent damage to the combustion chamber and turbine areas. This can occur within a few flights of the event, so just cranking down the idle was never an option.

Love the lightning story, hadn't heard that one before.

Quote:

| I was in the Air Training Corps in Bristol in the late 80s and flew in the Chipmunks based at Filton. Used to see the spare Concorde sitting there outside the hangar. |

Quote:

| And a question of my own - I've heard that the engines were pretty powerful even at ground idle, so powerful that if all 4 were running then a tug would not be able to push her back. Any truth to this? Were just 2 started, pushback and then start the remainder? Also heard that the pilots had to watch the brake temps whilst taxiing out to takeoff - was this also due to the power? |

) meant that a one engine in each nacelle pair had to be started on the gate, and the other in each nacelle started after push. Having a symetrical pair started enabled all 3 hydraulic systems, and hence most of the critical systems to be checked puring pushback.

) meant that a one engine in each nacelle pair had to be started on the gate, and the other in each nacelle started after push. Having a symetrical pair started enabled all 3 hydraulic systems, and hence most of the critical systems to be checked puring pushback.

Brake temperatures always had to be monitored; they really could get very hot. If a wheel was still too warm after T/O, then the gear would be left down just a little longer to aid cooling. (Each brake also had an electric cooling fan).

Idle thrust was always a problem in that it was too high; there was a 'lo idle' setting, but depending on the temperature of the day the difference was not that big. You could not just reduce idle some more because of a malady known as rotating stall. This can plague any engine, but the Olympus 593 was particularly susceptible. At very low idle speeds, pockets of air 'rotate' around the first few compressor stages and can completely alter the airflows through the engine. It is important that the engine is always accelerated quickly through this zone on start-up, because serious damage can occur if the engine runs for any period of time in the rotating stall region. If the engine DOES operate in this zone, then the combustion process can even occur in the last few stages of the HP compressor, causing extreme damage. This damage, although malignant, can result in blade failure and the subsequent damage to the combustion chamber and turbine areas. This can occur within a few flights of the event, so just cranking down the idle was never an option.

31st Aug 2010, 18:04

permalink Post: 170

DozyWannabe

Good point I suppose, but you could say that the six Concorde prototypes, Pre-Production and Production Series Test aircraft were also development aircraft, and yet more or less worked just as it said on the tin', where the TU144, in spite of all the facilities of Andrei Tupolev's design bureaux, not to mention more or less unlimited Soviet state funds produced a machine that in my opinion really BELONGED in a tin can. (I know this is all off topic, honest guys, I won't mention this stuff again

).

).

In reality the Soviets really lacked both propulsion technology as well as the systems expertise required to build an aircraft with even a remote hope of Mach 2 cruise, let alone safe and comfortable enough for fare paying passengers. The original aircraft had all for engines in one giant nacelle, and the landing gear retracted into the engine inlet duct itself, great for an undistorted flow path to the engines . The variable inlets were manually operated by the flight engineer as well, no automatics here. In the mid 1970's the Russians even approached PLESSEY to build a digital engine control unit for the TU144. A similar PLESSEY unit had been VERY successfully flight trialled on production series aircraft 202 (G-BBDG) and only lack of funds prevented it being used on the production aircraft. As this unit could obviously be used for Soviet military applications, there was objection from the UK government, and more than just a little trans-Atlantic pressure applied, and so this venture never happened.

. The variable inlets were manually operated by the flight engineer as well, no automatics here. In the mid 1970's the Russians even approached PLESSEY to build a digital engine control unit for the TU144. A similar PLESSEY unit had been VERY successfully flight trialled on production series aircraft 202 (G-BBDG) and only lack of funds prevented it being used on the production aircraft. As this unit could obviously be used for Soviet military applications, there was objection from the UK government, and more than just a little trans-Atlantic pressure applied, and so this venture never happened.

Until the advent of the Mig-29 and Sukhoi SU-27 this really was not the case. I'm afraid I'm with galaxy flyer on this; If you look at the air war over Vietnam, when an F4 met a MIG 19 or MIG 21 in an even air-to-air combat, the MIG was going down. (OK this could be partially down to superior US pilot traing etc, but if you look at the handful of skirmishes where the 1960's/1970's Soviet aircraft were engaged in Combat against US or French built fighters, the MIGs never really did very well at all). However, the aircraft that the Russians have been producing from the Mig 29 onwards seem to be in a completely different class now; hope they really are the good guys now.

ANYWAY, back on topic

Lurking SLF

No problem at all Darragh, please keep visiting us and post here also anytime.

Nick Thomas

I'm not sure that I can describe the DEBOW process remotely as eloquently as my friend Bellerophon did, I particularly loved the 'out of balance tumble-drier' bit, but starting a hot or even warm engine, even at DEBOW, you could certainly 'feel' the noise on the flight deck, until the shaft distortions evened out.

Now for the PFM bit, equally eloquently alluded to by Bellerophon:

DEBOW itself was maintained by a special sub-idle datum in the electronic Engine Control Unit, and once the engine was accelerated towards normal idle (61-65% N2, depending on the temperature of the day) even if the switch described by Bellerophon was accidently re-selected, an electronic inhibit gate in the ECU prevented this sub-idle datum from being used again that engine cycle.

You're welcome Nick, actually the roll and yaw trims operated in a similar manner to the pitch, although of course these was applied by a manual trim wheel only. (No French bike bell either

). Rotation of either wheel (more a giant knob actually) merely shifted the neutral datum of the relevant artificial feel unit, which in turn shifted the rudder pedals or control yoke; the resolvers for the FBW system would in consequence demand this 'trimmed' control surface movement.

). Rotation of either wheel (more a giant knob actually) merely shifted the neutral datum of the relevant artificial feel unit, which in turn shifted the rudder pedals or control yoke; the resolvers for the FBW system would in consequence demand this 'trimmed' control surface movement.

Dude

Quote:

| Well, it was essentially a development airframe pressed into premature service for the sake of beating a western project into the air. One wonders whether the story would have been different if the designers had been allowed to take their time and develop it properly. |

).

).

In reality the Soviets really lacked both propulsion technology as well as the systems expertise required to build an aircraft with even a remote hope of Mach 2 cruise, let alone safe and comfortable enough for fare paying passengers. The original aircraft had all for engines in one giant nacelle, and the landing gear retracted into the engine inlet duct itself, great for an undistorted flow path to the engines

. The variable inlets were manually operated by the flight engineer as well, no automatics here. In the mid 1970's the Russians even approached PLESSEY to build a digital engine control unit for the TU144. A similar PLESSEY unit had been VERY successfully flight trialled on production series aircraft 202 (G-BBDG) and only lack of funds prevented it being used on the production aircraft. As this unit could obviously be used for Soviet military applications, there was objection from the UK government, and more than just a little trans-Atlantic pressure applied, and so this venture never happened.

. The variable inlets were manually operated by the flight engineer as well, no automatics here. In the mid 1970's the Russians even approached PLESSEY to build a digital engine control unit for the TU144. A similar PLESSEY unit had been VERY successfully flight trialled on production series aircraft 202 (G-BBDG) and only lack of funds prevented it being used on the production aircraft. As this unit could obviously be used for Soviet military applications, there was objection from the UK government, and more than just a little trans-Atlantic pressure applied, and so this venture never happened.

Quote:

| Those "agricultural" fighters can mix it up with the best the west has to offer (until - or if - the F22 comes online) in terms of manoeuvering ability, if not in terms of weapons. |

ANYWAY, back on topic

Lurking SLF

No problem at all Darragh, please keep visiting us and post here also anytime.

Nick Thomas

Quote:

| M2dude I have another question concerning "debow" You very clearly answered my original question on another thread. I just wondered how the engine was kept at a sub idle 30% N2? Was it done by careful metering of the fuel? and if not how was it done? I ask because the throttles would be closed during start up. |

Now for the PFM bit, equally eloquently alluded to by Bellerophon:

DEBOW itself was maintained by a special sub-idle datum in the electronic Engine Control Unit, and once the engine was accelerated towards normal idle (61-65% N2, depending on the temperature of the day) even if the switch described by Bellerophon was accidently re-selected, an electronic inhibit gate in the ECU prevented this sub-idle datum from being used again that engine cycle.

Quote:

| Thanks for the explanation of how the pitch was "trimmed" Due to Concorde having elevrons instead of ailerons; was the aileron trim dealt with in a similar way? I guess the rudder trim could be applied normally. |

). Rotation of either wheel (more a giant knob actually) merely shifted the neutral datum of the relevant artificial feel unit, which in turn shifted the rudder pedals or control yoke; the resolvers for the FBW system would in consequence demand this 'trimmed' control surface movement.

). Rotation of either wheel (more a giant knob actually) merely shifted the neutral datum of the relevant artificial feel unit, which in turn shifted the rudder pedals or control yoke; the resolvers for the FBW system would in consequence demand this 'trimmed' control surface movement.

Dude

15th Sep 2010, 15:40

permalink Post: 364

Quote:

|

Considering the era in which the Concorde was produced I am curious as to why there was no APU fitted. It would seem to have been quite an inconvenience at times.

Was there ever any consideration given to fitting one and was the decision against the installation solely a weight issue ? |

The subject was dealt with in some depth, and in the course of the discussion is was described how the two preproduction and the first two production aircraft were equipped with an MEPU (monopropellant emergency power generator).

I've only just found this photo again... it's the MEPU of Delta Golf (202 - G-BBDG).

The photo was taken after 'DG was moved to the Brooklands museum, but before the tail cone was put back into place.

CJ

28th Sep 2010, 22:58

permalink Post: 492

Quote:

|

My question concerns lighting. Not many decent pictures showing landing lights etc being used in anger.

Concorde appears to have a much reduced frontal area for the housing of such lighting. |

Nevertheless there were three separate sets of landing/taxi lights there.

Quoting from the manual:

Two main landing lamps, one mounted in each wing root leading

edge, have retractable/extensible mountings and when not in

use are retracted in the lamp housing.

Two land/taxi lamps, similar to the main landing lamps, are attached to the

nose landing gear bay doors. The land/taxi lamps extend to

an intermediate position for landing, upon which they

automatically extend to the full position for taxiing, thus

changing the beam angle to compensate for the attitude change.

Two taxi/turn-off lamps, one mounted on each side of the

forward fuselage, provide ground illumination to identify

runway turn-off points.

These are the 'main' lights in the wing leading edge (600W each).

These are the lights in the nosewheel doors ("only" 450W each).

Quote:

| There is also the question of lenses having to withstand supersonic flow. |

The heat was less of a problem, actually.

The lights themselves were high-power sealed-beam units, the main units were 6 00W each, and the ones in the nosewheel doors were 450W ... nothing like your car headlights.

As a matter of fact, on the ground you were not suppossed to turn them on any more than 5 minutes in any 10 minutes.... they got a lot hotter when switched on, than they did in supersonic flight.

Quote:

| And also the angle of attack on landing (hope I have the right terminology there) seemingly pointing any lighting into the sky. |

What happened was that the main landing lamps in the wing roots were angled such, that they pointed straight ahead at the right angle to "hit" the runway during the landing itself.

Once the aircraft touched down, the land/taxi lights in the nose gear door extended further and lit a wider expanse of the runway ahead (see the earlier quote from the manual).

And then the third set of lights in the nose helped you to find the turn-off to the taxiway.

One nice little detail.... on F-BTSD, the Concorde at the French Le Bourget museum, those lights still work, and on G-BBDG, the Concorde at the Brooklands museum that was saved from the scrapheap, they brought those lights back to life, too.

CJ

Last edited by ChristiaanJ; 28th Sep 2010 at 23:14 . Reason: Addng pics and typo

16th Oct 2010, 22:27

permalink Post: 580

OK, I see others have already posted answers.

I've carefully avoided looking at them, but I'll might as well plug in mine now.

My personal problem is that I was involved in the very earliest days, before the aircraft went into service, and then in the last days and afterwards...

So the questions dealing with the in-service period are totally outside my field of experience... all I can do is guess, in case I saw the answers somewhere.

1) How many Concorde airframes were built?

Twenty-two.

Two static-test airframes.

- One at Toulouse, for purely static tests, and tests such as vibration and flutter.

- One at Farnborough, for the long-duration thermal fatigue tests.

(A few bits and pieces of the Farnborough test specimen have survived, and can still be seen at the Brooklands museum).

Two prototypes (001 and 002)

Two pre-production aircraft (01 and 02)

Two production aircraft used for certification, that never entered service (201 - F-WTSB and 202 - G-BBDG)

Fourteen production aircraft, seven that served with British Airways, seven that served with Air France.

2) As far as the British constructed aircraft went, name the destinations that were served?. Regular flight numbers only, excludes charters etc.

Not a clue as to the full list.

- Bahrain, obviously.

- JFK.

- IAD (not sure if that's rated as regular, or only incidental)

- Dallas (with Braniff)

- Barbados (of course, right until the end)

- Sngapore (with Singapore Airlines, and G-BOAD in Singapore Airlines colours on one side)

- Sydney (again no idea if that rated as a regular flight or only a few tries)

3) What was the departure time for the ORIGINAL morning LHR-JFK Concorde services? (Not called the BA001 then either).

Not a clue either. Vague memory of about 10:00 am which gave you a full working day in New York.

4) Further to question 3 above, what WERE the original flight numbers for the BA001 and BA003? (The morning and evening LHR-JFK services?)..

Never flew on them, never had to deal with them.

BA174 comes to mind from the depths of my memory, in that case BA003 would have been BA176?

5) There were no less than FORTY SIX fuel pumps on Concorde. What was the breakdown for these? (Clue; don't forget the scavenge pump )

M2dude, I did AFCS, not the fuel system. I believe you, but without pulling out some diagrams I honestly have NO idea.

I expect each tank had at least two pumps, which gets me up to 26.

Then there were a few emergency pumps for the trim tanks, and I suppose each engine had additional pumps associated with it.

Still nowhere near the 46 I need to find.....

6) What airframe had the only TOTALLY unique shape?

That would have been my old friend, 01 (G-AXDN), first pre-production aircraft, now at Duxford.

It was the first Concorde with the new transparent visor, but it still had the short tail that characterised the prototypes.

It was 02 (F-WTSA), the first French pre-production aircraft, that was close to the final shape of the production aircraft.

7) This one is particularly aimed at ChristiaanJ. What was the total number of gyros on the aircraft?

Good question.... never counted them all. But I'll try a guess.

First a nice one, the SFENA Emergency Standby Artificial Horizon (made by the firm I worked for).

Ran off the Emergency Battery Bus via a small independent inverter.

And if that failed too, it would still run reliably for several minutes on its own inertia.

Next, the rate gyros used by the autostabilisation system ; these measured the angular rate of the aircraft along the three main axes, pitch, roll and yaw.

There were six, three each for the two autostab systems.

Now the rest....

Each IMU (inertial measurement unit, part of the inertial naviagation system) had three gyros.

With three INS on board, that would make nine.

Much as I try, I can't remember other ones, so I'll look forward to the final answer.

I can imagine the weather radar using an additional gyro for stabilisation, but I never went there.

8) How many wheel brakes?

Unless this is a trick question, I would say eight, for each of the main gear wheels.

The nose gear did not have any brakes - unless there were some small ones to stop the wheels rotating after retraction of the gear, but not used during landing.

9) What Mach number was automatic engine variable intake control enabled?

No idea.

Mach 1.0 or thereabouts is my personal guess only.

10) Above each bank of engine instruments were three lights, a blue, a green and an amber. What did they each signify?

I know that they each monitored the status of one of the engines, because it was too complex for the pilots to fully monitor all the parameters of all four engines in the short time between start-of-roll and V1... they had too many other things to do.

But I don't remember what each light meant, would have to look it up in the manual.

11) At what airfied were the first BA crew base training details held?

No idea.

Was it Brize Norton, or Casablanca?

12) What LHR runways did Concorde use for landing and take-off? (Trick question, not as obvious as it might seem).

No idea.

Vague memory of it being systematically the North runway for noise issues.

13) What operator had serious plans to operate Concorde from SNN to JFK in the early 1980's?

No idea.

14) What development aircraft did not exceed Mach 2 until fifteen months after her maiden flight?

I would expect the obvious answer to be 002.

Working up from first flight to Mach 2 was a slow and laborious process, and in the end it was 001 that both flew first, and also went to Mach 2 first.

I don't think any of the other aircraft took that long.

A I said, I tried to answer all questions "off the top of my head", without looking at any other sources.

CJ

I've carefully avoided looking at them, but I'll might as well plug in mine now.

Quote:

|

Originally Posted by

M2dude

If you were never personally involved withe the aircraft you can leave out the really stinky questions if you want.

|

So the questions dealing with the in-service period are totally outside my field of experience... all I can do is guess, in case I saw the answers somewhere.

1) How many Concorde airframes were built?

Twenty-two.

Two static-test airframes.

- One at Toulouse, for purely static tests, and tests such as vibration and flutter.

- One at Farnborough, for the long-duration thermal fatigue tests.

(A few bits and pieces of the Farnborough test specimen have survived, and can still be seen at the Brooklands museum).

Two prototypes (001 and 002)

Two pre-production aircraft (01 and 02)

Two production aircraft used for certification, that never entered service (201 - F-WTSB and 202 - G-BBDG)

Fourteen production aircraft, seven that served with British Airways, seven that served with Air France.

2) As far as the British constructed aircraft went, name the destinations that were served?. Regular flight numbers only, excludes charters etc.

Not a clue as to the full list.

- Bahrain, obviously.

- JFK.

- IAD (not sure if that's rated as regular, or only incidental)

- Dallas (with Braniff)

- Barbados (of course, right until the end)

- Sngapore (with Singapore Airlines, and G-BOAD in Singapore Airlines colours on one side)

- Sydney (again no idea if that rated as a regular flight or only a few tries)

3) What was the departure time for the ORIGINAL morning LHR-JFK Concorde services? (Not called the BA001 then either).

Not a clue either. Vague memory of about 10:00 am which gave you a full working day in New York.

4) Further to question 3 above, what WERE the original flight numbers for the BA001 and BA003? (The morning and evening LHR-JFK services?)..

Never flew on them, never had to deal with them.

BA174 comes to mind from the depths of my memory, in that case BA003 would have been BA176?

5) There were no less than FORTY SIX fuel pumps on Concorde. What was the breakdown for these? (Clue; don't forget the scavenge pump )

M2dude, I did AFCS, not the fuel system. I believe you, but without pulling out some diagrams I honestly have NO idea.

I expect each tank had at least two pumps, which gets me up to 26.

Then there were a few emergency pumps for the trim tanks, and I suppose each engine had additional pumps associated with it.

Still nowhere near the 46 I need to find.....

6) What airframe had the only TOTALLY unique shape?

That would have been my old friend, 01 (G-AXDN), first pre-production aircraft, now at Duxford.

It was the first Concorde with the new transparent visor, but it still had the short tail that characterised the prototypes.

It was 02 (F-WTSA), the first French pre-production aircraft, that was close to the final shape of the production aircraft.

7) This one is particularly aimed at ChristiaanJ. What was the total number of gyros on the aircraft?

Good question.... never counted them all. But I'll try a guess.

First a nice one, the SFENA Emergency Standby Artificial Horizon (made by the firm I worked for).

Ran off the Emergency Battery Bus via a small independent inverter.

And if that failed too, it would still run reliably for several minutes on its own inertia.

Next, the rate gyros used by the autostabilisation system ; these measured the angular rate of the aircraft along the three main axes, pitch, roll and yaw.

There were six, three each for the two autostab systems.

Now the rest....

Each IMU (inertial measurement unit, part of the inertial naviagation system) had three gyros.

With three INS on board, that would make nine.

Much as I try, I can't remember other ones, so I'll look forward to the final answer.

I can imagine the weather radar using an additional gyro for stabilisation, but I never went there.

8) How many wheel brakes?

Unless this is a trick question, I would say eight, for each of the main gear wheels.

The nose gear did not have any brakes - unless there were some small ones to stop the wheels rotating after retraction of the gear, but not used during landing.

9) What Mach number was automatic engine variable intake control enabled?

No idea.

Mach 1.0 or thereabouts is my personal guess only.

10) Above each bank of engine instruments were three lights, a blue, a green and an amber. What did they each signify?

I know that they each monitored the status of one of the engines, because it was too complex for the pilots to fully monitor all the parameters of all four engines in the short time between start-of-roll and V1... they had too many other things to do.

But I don't remember what each light meant, would have to look it up in the manual.

11) At what airfied were the first BA crew base training details held?

No idea.

Was it Brize Norton, or Casablanca?

12) What LHR runways did Concorde use for landing and take-off? (Trick question, not as obvious as it might seem).

No idea.

Vague memory of it being systematically the North runway for noise issues.

13) What operator had serious plans to operate Concorde from SNN to JFK in the early 1980's?

No idea.

14) What development aircraft did not exceed Mach 2 until fifteen months after her maiden flight?

I would expect the obvious answer to be 002.

Working up from first flight to Mach 2 was a slow and laborious process, and in the end it was 001 that both flew first, and also went to Mach 2 first.

I don't think any of the other aircraft took that long.

A I said, I tried to answer all questions "off the top of my head", without looking at any other sources.

CJ

5th Nov 2010, 11:56

permalink Post: 663

I have to admit that some of the subsonic fuel burn figures for Concorde were truly eye watering, and without massive engine and airframe modifications there was precious little in service that could be done to improve things. Paradoxically improvements to the

supersonic

efficiency of the powerplant were easier to implement, and several modifications were implemented, tried or proposed to improve fuel burn:

Way back in the late 1970's we did a major modification to the intakes that increased capture area by 2.5% and gave us typically a 1.6% improvement in trans-Atlantic fuel burn, and although this was our biggest performance improvement modification, there were more:

The famous elevon and rudder trailing edge extension modifications (that due to poor design, produced in later life the water ingress induced honeycomb failures) together with the re-profiled fin leading edge modification, I never saw the performance gains quantified (anyone have any ideas?).

Can anyone here remember the riblet trial? In the mid 1990's Airbus supplied 'stick on' plastic riblets, applied to various areas on the under-side of the wing on G-BOAG. These riblets had very fine undulations moulded into the surface; the idea being that as the air flowed through and around the riblet patches, boundary layer turbulence, and hence induced drag would be reduced. Now, the performance gains (if any) were never quantified, mainly because the riblet patches either peeled off or the surface deteriorated with the continuous thermal cycle. (I was over in JFK when the aircraft first arrived after having the riblets fitted, and as the crew were trying to proudly show me these amazing aerodynamic devices, they were sadly embarassed, as several had dissapeared in the course of a single flight).

There was one modification, proposed by Rolls Royce in the late 1990's that did have quite a lot of potential; this was to increase the engine N1 by around 1.5%. This would have had the effect of increasing engine mass flow and therefore reducing the drag inducing spill of supersonic air over the lower lip of the intake. Depending on the temperature, the performance gains were in the order of a 1.5% improvement in fuel burn at ISA Plus upper atmosphere temperatures ('normal' LHR-JFK) to none at all at significant ISA Minus temperatures (LHR -BGI). The modifacation had been trialed on G-BBDG before her retirement in the early eighties, and was proven in terms of performance enhancement and engine stability. In order to keep TET at the pre-modification level, there was a small increase in N2 commanded also. (The higher N1 required an increase in primary nozzle area, reducing TET). The main reason for the modification not being implemented was one of cost; The Ultra Electronics Engine Control Units were analog units, and the modification was a simple replacement of two resistors per unit. However because ultimate mass flow limitation was also controll by the digital AICU (built by British Aerospace Guided Weapons Division) the cost of getting a software update for this exremely 'mature' unit was found to be prohibitive.

A certain 'brainy' SEO and myself were working on a modification to improve fuel burn on ISA minus sectors. The idea was to force the autopilot, in Max Cruise at low temperatures only , to fly the aircraft close to Mmo, rather than at Max Cruise speed of Mach 2 - 2.02; this would have given us gains of up to 1%, depending on the temperature. The basic electronics involved for the modification were relatively straightforward, but it was never pursued due to the complexity of dealing with temperature shears and the cost of certification.

Dude

Way back in the late 1970's we did a major modification to the intakes that increased capture area by 2.5% and gave us typically a 1.6% improvement in trans-Atlantic fuel burn, and although this was our biggest performance improvement modification, there were more:

The famous elevon and rudder trailing edge extension modifications (that due to poor design, produced in later life the water ingress induced honeycomb failures) together with the re-profiled fin leading edge modification, I never saw the performance gains quantified (anyone have any ideas?).

Can anyone here remember the riblet trial? In the mid 1990's Airbus supplied 'stick on' plastic riblets, applied to various areas on the under-side of the wing on G-BOAG. These riblets had very fine undulations moulded into the surface; the idea being that as the air flowed through and around the riblet patches, boundary layer turbulence, and hence induced drag would be reduced. Now, the performance gains (if any) were never quantified, mainly because the riblet patches either peeled off or the surface deteriorated with the continuous thermal cycle. (I was over in JFK when the aircraft first arrived after having the riblets fitted, and as the crew were trying to proudly show me these amazing aerodynamic devices, they were sadly embarassed, as several had dissapeared in the course of a single flight).

There was one modification, proposed by Rolls Royce in the late 1990's that did have quite a lot of potential; this was to increase the engine N1 by around 1.5%. This would have had the effect of increasing engine mass flow and therefore reducing the drag inducing spill of supersonic air over the lower lip of the intake. Depending on the temperature, the performance gains were in the order of a 1.5% improvement in fuel burn at ISA Plus upper atmosphere temperatures ('normal' LHR-JFK) to none at all at significant ISA Minus temperatures (LHR -BGI). The modifacation had been trialed on G-BBDG before her retirement in the early eighties, and was proven in terms of performance enhancement and engine stability. In order to keep TET at the pre-modification level, there was a small increase in N2 commanded also. (The higher N1 required an increase in primary nozzle area, reducing TET). The main reason for the modification not being implemented was one of cost; The Ultra Electronics Engine Control Units were analog units, and the modification was a simple replacement of two resistors per unit. However because ultimate mass flow limitation was also controll by the digital AICU (built by British Aerospace Guided Weapons Division) the cost of getting a software update for this exremely 'mature' unit was found to be prohibitive.

A certain 'brainy' SEO and myself were working on a modification to improve fuel burn on ISA minus sectors. The idea was to force the autopilot, in Max Cruise at low temperatures only , to fly the aircraft close to Mmo, rather than at Max Cruise speed of Mach 2 - 2.02; this would have given us gains of up to 1%, depending on the temperature. The basic electronics involved for the modification were relatively straightforward, but it was never pursued due to the complexity of dealing with temperature shears and the cost of certification.

Dude

Last edited by M2dude; 5th Nov 2010 at 15:49 .

27th Nov 2010, 09:02

permalink Post: 790

ChristiaanJ

With respect my friend that is utter codswallop. You can doubt things all you want, they've already said that they would remove it all; that by definition means all the cabin side-walls, galleys and roof panels, as well as the underfloor areas. When G-BBDG (202) was cocooned at Filton they did just that, and

the only intact part of the interior left was the flight deck!!

Unfortunately, this lot have a habit of talking with forked tongue as far as Concorde goes; you can not in any way be sure about this, and we should really stop believing everything that this lot in Toulouse tell us . (Recent history here has taught us this all too well, and nothing would please scarebus more than there to be no reminders of Concorde at all on the airfield at Filton). More to the point, there is absolutely no certainty that the Cribb's Causeway site will ever be built anyway, you just can NOT say that the airframe will not ne broken up for road transportation, because if she does go to another museum in the absence of the Cribb's Causeway site being built, that will DEFINATELY happen. But at least we now have another 'written off' British Concorde; I guess this fact obviously pleases some people

Total crap I'm afraid Christian. You can doubt it all you want; you're entitled to your opinions as we all are here. But the fact remains that there is a certain producer of airframes in Europe that has come out with nothing but lies and deceit with regard to Concorde, since early 2003, and it continues to do so to this day. (Guesses anyone?) You conveniently seem to forget that it was

scarebus themselves

who unilaterally closed the Concorde Filton exhibit...'for maintenace' ..

YET ANOTHER TOTAL PACK OF LIES!!

And as far as responding to pressures; They could not give a flying about Concorde pressures, they

JUST DO NOT WANT TO KNOW!!

And yes they are fed up with Concorde.. poor dears. Perhaps OAF should never have gone to Filton in the first place; The continuing thought of Filton bending over backwards to please it's French masters makes one want to throw up. The basic fact remains that any British Concorde anywhere NEAR an Airbus plant is nothing more than an embarassment to them, and is fundimantally always in jeapordy.

about Concorde pressures, they

JUST DO NOT WANT TO KNOW!!

And yes they are fed up with Concorde.. poor dears. Perhaps OAF should never have gone to Filton in the first place; The continuing thought of Filton bending over backwards to please it's French masters makes one want to throw up. The basic fact remains that any British Concorde anywhere NEAR an Airbus plant is nothing more than an embarassment to them, and is fundimantally always in jeapordy.

Big deal, she needed a C Check. Unlike in France, a Concorde major (D check) here did not take over a year to complete, and an inter could be in and out of the shed in a couple of months. Oh, and the check was completed correctly and thoroughly.

I tend to agree with the RTF point, the \xa3\xa3\xa3\xa3\xa3's involved are generally prohibitive and it will probably never happen, but you and I have been in aviation long enough to realise that nothing is impossible. (At least not this side of the Channel). All aircraft left outside in the elements are obviously going to suffer, and it is irony of ironies that the FRENCH aircraft are generally stored indoors in the dry and warm, where the British were ALL intitially stored outside, exposed to the elements. (Only OAC in Manchester and OAE in BGI are now finally cared for under cover, the poor old 'wing clipped' OAA in Edinburgh does not really count). This ridiculous fact is is a source of both wonder and ANGER in the minds of most Concorde people in the UK. (Makes me sick personally!!).

Dude

Quote:

| With the lack of comm from Airbus, of course we don't know the details, but I would have thought the problem is essentially the under-floor insulation, the same that causes the musty smell in the Fox-Charlie cockpit. If so, I doubt they'd bother to strip the cabin. |

Quote:

| At present, the 'permanent home' is planned to be at Cribb's Causeway, where land is already available. Since this is only just on the other side of Filton airfield, so far there is no question of breaking up the airframe, or road transport. |

Unfortunately, this lot have a habit of talking with forked tongue as far as Concorde goes; you can not in any way be sure about this, and we should really stop believing everything that this lot in Toulouse tell us . (Recent history here has taught us this all too well, and nothing would please scarebus more than there to be no reminders of Concorde at all on the airfield at Filton). More to the point, there is absolutely no certainty that the Cribb's Causeway site will ever be built anyway, you just can NOT say that the airframe will not ne broken up for road transportation, because if she does go to another museum in the absence of the Cribb's Causeway site being built, that will DEFINATELY happen. But at least we now have another 'written off' British Concorde; I guess this fact obviously pleases some people

Quote:

| I doubt this.... The "pressures" from these bodies and people consist only of noises on internet forums and in the press. As long as BA (as the owner), Airbus (as the current 'guardian' and legacy manufacturer) and the CAA (as the regulatory body) say "NO", Airbus knows perfectly well it'll never happen, pressures or no pressures. My own take is simply, that they're fed up with a Concorde on their site, that their early 'enthusiasts' who campaigned for 'A Concorde at Filton' have now left, and that it's now Airbus exerting pressure on the Concorde Trust and other bodies to provide that 'permanent home' they've been talking about for years. |

And as far as responding to pressures; They could not give a flying

about Concorde pressures, they

JUST DO NOT WANT TO KNOW!!

And yes they are fed up with Concorde.. poor dears. Perhaps OAF should never have gone to Filton in the first place; The continuing thought of Filton bending over backwards to please it's French masters makes one want to throw up. The basic fact remains that any British Concorde anywhere NEAR an Airbus plant is nothing more than an embarassment to them, and is fundimantally always in jeapordy.

about Concorde pressures, they

JUST DO NOT WANT TO KNOW!!

And yes they are fed up with Concorde.. poor dears. Perhaps OAF should never have gone to Filton in the first place; The continuing thought of Filton bending over backwards to please it's French masters makes one want to throw up. The basic fact remains that any British Concorde anywhere NEAR an Airbus plant is nothing more than an embarassment to them, and is fundimantally always in jeapordy.

Quote:

| In 2003, the issue with G-BOAF was that she was almost 'out of hours', with only a few hours left until the next big overhaul (an 'Inter', IIRC). At the time, this was the reason why G-BOAF did not partake to the full extent in the flying during the last months, so as to have a few hours 'spare' for the last few flights, and of course the final flight. |

Quote:

| And that's another reason why Airbus wouldn't be bothered by those "pressures" mentioned earlier... they know perfectly well nobody is going to come up with the \xa3100M +++ to re-create the necessary infrastructure. |

I tend to agree with the RTF point, the \xa3\xa3\xa3\xa3\xa3's involved are generally prohibitive and it will probably never happen, but you and I have been in aviation long enough to realise that nothing is impossible. (At least not this side of the Channel). All aircraft left outside in the elements are obviously going to suffer, and it is irony of ironies that the FRENCH aircraft are generally stored indoors in the dry and warm, where the British were ALL intitially stored outside, exposed to the elements. (Only OAC in Manchester and OAE in BGI are now finally cared for under cover, the poor old 'wing clipped' OAA in Edinburgh does not really count). This ridiculous fact is is a source of both wonder and ANGER in the minds of most Concorde people in the UK. (Makes me sick personally!!).

Dude

Last edited by M2dude; 27th Nov 2010 at 14:21 .

28th Nov 2010, 17:27

permalink Post: 799

ChristiaanJ

There is THIS link from Gordon Roxborough's superb 'ConncordeSST site' CONCORDE SST : 10th Anniversary

As you can see the event occured on Christmas Eve in 1985. As you can see from the video, Capt John Hutchinson was also aboard G-BOAG as a commentator, the F/O being John 'Noj' White. (After leaving the fleet when he got his command, Noj eventually returned to Concorde many years later as Capt Noj).

At the bottom of the web page I am 99% sure that Gordon got it wrong when he said that the reason that there were only 6 aircraft for the Boxing day 'group photo' was that the seventh aircraft was in the paint shop. I was there when we did the photo shoot, and I am pretty sure the only reason we never had aircraft 7 was that it was in JFK.

CAAAD

I wouldn't be at all surprised (the Ultra ECA was a real steam powered piece of kit) but we always managed to get obsolete/obsolescent electron component somewhow. I remember when we test flew the Plessey (I think) digital ECA on G-BBDG in the late 1970's it was a fraction of the size, ran cooler and the engine parameters were more stable too. Such a pity that we never went down that road for the production aircraft.

Regards

Dude

There is THIS link from Gordon Roxborough's superb 'ConncordeSST site' CONCORDE SST : 10th Anniversary

As you can see the event occured on Christmas Eve in 1985. As you can see from the video, Capt John Hutchinson was also aboard G-BOAG as a commentator, the F/O being John 'Noj' White. (After leaving the fleet when he got his command, Noj eventually returned to Concorde many years later as Capt Noj).

At the bottom of the web page I am 99% sure that Gordon got it wrong when he said that the reason that there were only 6 aircraft for the Boxing day 'group photo' was that the seventh aircraft was in the paint shop. I was there when we did the photo shoot, and I am pretty sure the only reason we never had aircraft 7 was that it was in JFK.

CAAAD

Quote:

| Dude - I think basic engine hardware was in good supply, but there were concerns about the control amplifier component availability. |

Regards

Dude

2nd Dec 2010, 11:33

permalink Post: 823

howiehowie93

Welcome aboard and thank you for your kind words; I am so glad you enjoy our thread. You are in good company here also, many of the 'more mature' vintage Concorde people (like me) are ex-RAF. (And some of the pilots were ex-RN also, but no one is perfect

(like me) are ex-RAF. (And some of the pilots were ex-RN also, but no one is perfect

... only joking guys).

... only joking guys).

It is a matter of pride/embarrassment for me that up to the end of 2003, I'd only ever really 'known' two aircraft; the C-130 and Concorde .

.

I was really interested in some of the RB199/Olympus similarities; TBP was tried on the development aircraft for engine control TET calculation, but Rolls-Royce were unhappy with the performance and abandoned TBP in favour of indirectly computing TET as a function of T1 (intake TAT) and EGT (T7). (And this meant the removal of the four TBP amplifiers too... we had even more black boxes then.

As for the three 'control amps' you were speaking of, I'm 99% sure that A/C 101, G-AXDN still does have the units you described fitted. The ECUs (or ECAs as they were sometimes called) were a highly complex analog control unit built by Ultra Electronics. They could be quite a headache sometimes in terms of reliability, but would generally perform flawlessly in terms of engine control. As with any analog box, control law changes in the field were not too straightforward and a soldering iron was the flight test engineers best friend here. The Reheat Amp was built by ELECMA (the electronics arm of SNECMA) and unlike some of the other components in the reheat system, was a beautifully designed and constructed unit. Very few reheat failures (and there were many) were attributed to the 'box' itself. The main fragility with the reheat system was the ignition system used (a 20 KV swirl ignitor, which you will see is covered previously in the thread). We (BA/RR) were seriously looking at one point of investigatng the use of 'hot streak' injection as a backup ignition source, which I believe was used in the 199 (?), but it unfortunately never happened. The Plessey DECU that was tried on A/C 202 (G-BBDG) DID combine main engine control and reheat, but unfortunately was never taken up for the production A/C, and so we were left withe the '3 AMPS' as you so eloquently describe. We had a total of THIRTY ONE control units associated with powerplant control on Concorde; might be a little different now methinks ]

]

Thanks for some of the fascinating engine history snippets you shared with us, although purists might regard it as being 'off topic' I personally think this rather unique thread is all the better for your contribution here,

I think it is great that you are working with industrial Olympuses, all part of the family tree. I will dig out the verboten sustained N1 speed band for the 593, it certainly WAS a fact though.

Thanks from all of us for your contribution here Howie, keep on posting.

Regards

Dude

Welcome aboard and thank you for your kind words; I am so glad you enjoy our thread. You are in good company here also, many of the 'more mature' vintage Concorde people

(like me) are ex-RAF. (And some of the pilots were ex-RN also, but no one is perfect

(like me) are ex-RAF. (And some of the pilots were ex-RN also, but no one is perfect

... only joking guys).

... only joking guys).

It is a matter of pride/embarrassment for me that up to the end of 2003, I'd only ever really 'known' two aircraft; the C-130 and Concorde

.

.

I was really interested in some of the RB199/Olympus similarities; TBP was tried on the development aircraft for engine control TET calculation, but Rolls-Royce were unhappy with the performance and abandoned TBP in favour of indirectly computing TET as a function of T1 (intake TAT) and EGT (T7). (And this meant the removal of the four TBP amplifiers too... we had even more black boxes then.

As for the three 'control amps' you were speaking of, I'm 99% sure that A/C 101, G-AXDN still does have the units you described fitted. The ECUs (or ECAs as they were sometimes called) were a highly complex analog control unit built by Ultra Electronics. They could be quite a headache sometimes in terms of reliability, but would generally perform flawlessly in terms of engine control. As with any analog box, control law changes in the field were not too straightforward and a soldering iron was the flight test engineers best friend here. The Reheat Amp was built by ELECMA (the electronics arm of SNECMA) and unlike some of the other components in the reheat system, was a beautifully designed and constructed unit. Very few reheat failures (and there were many) were attributed to the 'box' itself. The main fragility with the reheat system was the ignition system used (a 20 KV swirl ignitor, which you will see is covered previously in the thread). We (BA/RR) were seriously looking at one point of investigatng the use of 'hot streak' injection as a backup ignition source, which I believe was used in the 199 (?), but it unfortunately never happened. The Plessey DECU that was tried on A/C 202 (G-BBDG) DID combine main engine control and reheat, but unfortunately was never taken up for the production A/C, and so we were left withe the '3 AMPS' as you so eloquently describe. We had a total of THIRTY ONE control units associated with powerplant control on Concorde; might be a little different now methinks

]

]

Thanks for some of the fascinating engine history snippets you shared with us, although purists might regard it as being 'off topic' I personally think this rather unique thread is all the better for your contribution here,

I think it is great that you are working with industrial Olympuses, all part of the family tree. I will dig out the verboten sustained N1 speed band for the 593, it certainly WAS a fact though.

Thanks from all of us for your contribution here Howie, keep on posting.

Regards

Dude

20th Dec 2010, 15:40

permalink Post: 902

Point CG for Take off Performance - Post 893

Having found this superb thread back when it was at its page 8. It is a daily 'must check' for me, and is about to get more interesting because 'CliveL' is joining. Welcome Clive.

As the CAA surveyor/flight test engineer referred to in Clive's Post 893 I am happy to confirm that the discussion took place and we had a good result for the aeroplane. My logbook suggests it was March 1975 at Torrejon with G-BBDG.

I will try to dig back into 35 years ago memory banks and find a few more anecdotes of a fascinating development and certification programme.

Compliments of the season to all readers.

Andrew

As the CAA surveyor/flight test engineer referred to in Clive's Post 893 I am happy to confirm that the discussion took place and we had a good result for the aeroplane. My logbook suggests it was March 1975 at Torrejon with G-BBDG.

I will try to dig back into 35 years ago memory banks and find a few more anecdotes of a fascinating development and certification programme.

Compliments of the season to all readers.

Andrew

Last edited by asmccuk; 20th Dec 2010 at 15:46 . Reason: Correction to Title

25th Dec 2010, 22:37

permalink Post: 1007

Quote:

|

We all know Concorde went at Mach 2 at FL600, but were there instances (for the press, certification, etc) that you went supersonic considerably closer to the deck? and what issues (if any) did that bring up?

|

Flight envelope

Those are the official certified limits.

I doubt somehow anybody went beyond those "for the press".....

But during certification, yes, each of those limits was exceeded, slowly and carefully, to be able to draw those official operational limits on the document.

For instance, the certified Mmo is 2.04. During certification, G-BBDG (202) went to Mach 2.21....

Even while staying within the limits, she could could exceed Mach 1 just below 30,000 ft.

Also, during the acceptance flights after major overhauls, most of those envelope limits would be exceeded by a given margin, to prove the aircraft still met all the certification requirements. Whether any of that was done 'closer to the deck', I wouldn't know.

The 'issues' would vary. Performance would be one issue... Delta Golf (and 01, who went to Mach 2.23) basically "ran out of steam" at that speed.

Another issue would be that 'going beyond the borders' shortened the fatigue life of the airframe, and it was difficult to assess exactly by how much. It was one of the reasons why Delta Golf and Sierra Bravo (the certification aircraft) in the end never went into service.

CJ

15th Jan 2011, 10:59

permalink Post: 1100

A Journey Back In Time !!

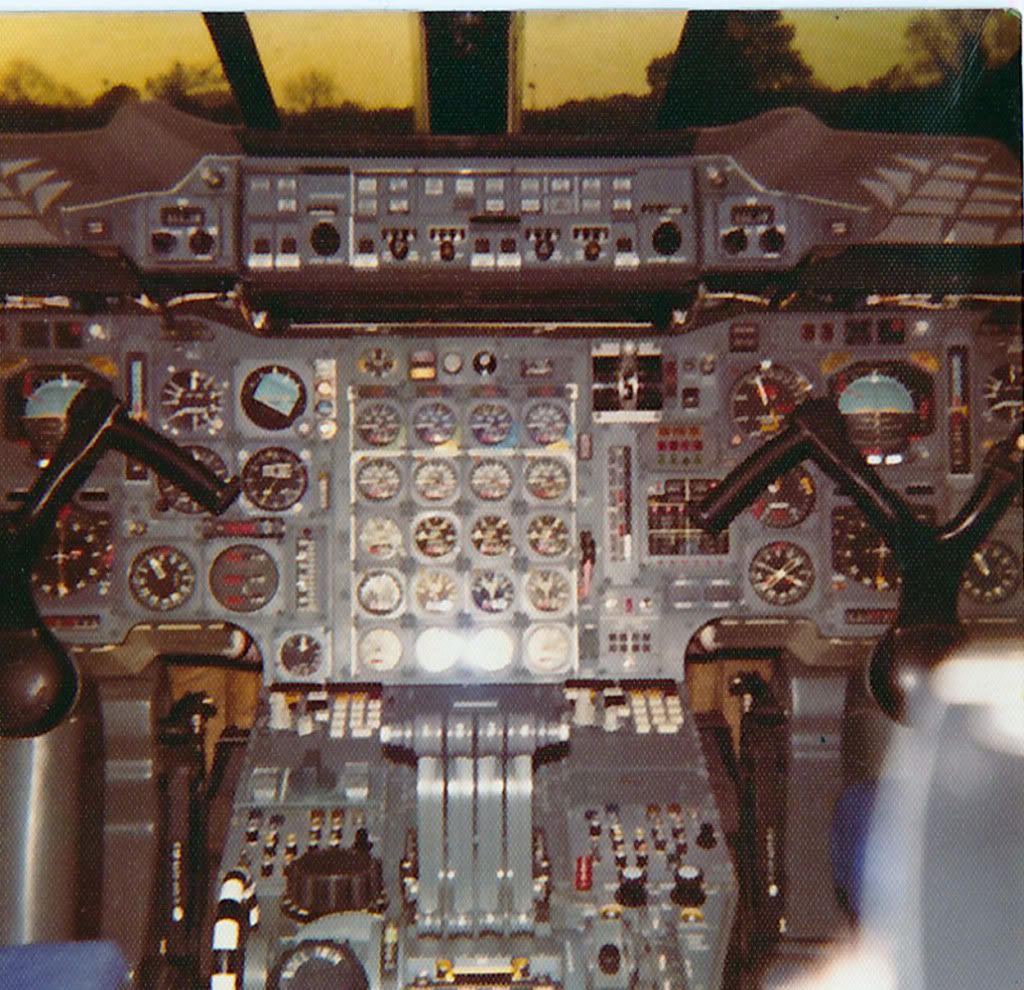

OK, here is a photo that I took at Fairford in November 1976. I'd just had my very first Concorde flight on a brand new G-BOAD, and took this flight deck photo in the hangar later that afternoon (the doors are open hence the late afternoon Cotswold sky. The point of this rather poor (sorry guys, I was young for goodness sake) photo is to look at just how subtly different the 1976 flight deck WAS.

The first thing I know EXWOK and BELLEROPHON will (maybe) notice is that originally OAD had a 'normal colour' electroluminescent light plate on the visor indication panel. (If I remember rightly (it was a million years ago chaps) when this one 'stopped lighting' we could not get a replacement and had to rob 202 (G-BBDG) at Filton; this one being the same black development aircraft colour that OAD has to this day.

The OTHER first thing that you may notice is the Triple Temperature Indicator on the captains dash panel. (The first officer had his in in similar position). These got moved around (twice in the end) when TCAS was installed in the mid-90's. It was amazing just how much equipment got moved around over the years, in order to 'shoe-horn in' various bits of extra equimpent.

The cabin altimeter here fitted just above the #1 INS CDU also got moved (to the centre consul) when the FAA 'Branniff' modifications were embodied later in the 70's. It's spot got occupied by a standy altimeter mandated by the FAA but this was removed after Branniff ceased flying Concorde; the cabin altimeter returning to it's former home. The REALLY observant will notice that there is neither an Autoland Ca3/Cat2 identifier on the AFCS panel (glued on by BA at LHR) or the famous and precision built 'Reheat Capabilty Indicator' flip down plate fitted to the centre dash panel a few years later by BA.

Also not shown here, as they were buyer furnished equipment also fitted at on delivery LHR, are the two ADEUs (Automatic Data Entry Units, or INS Card readers). These were located immediatel aft of the CDU's and were used for bulk waypoint loading ('bulk' being 9, the most that the poor old Delco INU memory could handle). These were removed in the mid 90's when the Navigation Database was fitted to Concorde INUs, and bulk loading then was achieved by simply tapping in a 2 digit code. (Hardly the elegence of FMS, but still very elegent in comparison with the ADEU's, and worked superbly). A little note about these ADEU things; You inserted this rather large optically read paper data card into the thing and the motor would suck the unsuspecting card in. As often as not the ADEU would chew the card up and spit the remnants out, without reading any data, or not even bother spitting out the remnants at all. Removing these things FINALLY when the INUs were modified was absolute joy!!

ps. When G-BOAG (then G-BFKW) was delivered in 1980 it had neither any of the Branniff mods or ADEUs fitted. (Also the INS was not wired for DME updating). This meant that obviously she could not fly IAD-DFW with Branniff but also she could not do LHR-BAH either, because of the lack ADEUs. (You could not manually insert waypoints quick enough over the 'Med', or so the guys told me. So for the first few years good old FKW/OAG just used to plod between LHR and JFK. And plod she did, superbly. She never did get the ADEUs (not necessary thank goodness when the INUs got modified) but we wired in DME updating and so she could navigate around with the best of them.

My gosh I do prattle on, sorry guys.

Best regards

Dude

PS Welcome back Landlady, hope you've recovered from your fall XXXX

The first thing I know EXWOK and BELLEROPHON will (maybe) notice is that originally OAD had a 'normal colour' electroluminescent light plate on the visor indication panel. (If I remember rightly (it was a million years ago chaps) when this one 'stopped lighting' we could not get a replacement and had to rob 202 (G-BBDG) at Filton; this one being the same black development aircraft colour that OAD has to this day.

The OTHER first thing that you may notice is the Triple Temperature Indicator on the captains dash panel. (The first officer had his in in similar position). These got moved around (twice in the end) when TCAS was installed in the mid-90's. It was amazing just how much equipment got moved around over the years, in order to 'shoe-horn in' various bits of extra equimpent.

The cabin altimeter here fitted just above the #1 INS CDU also got moved (to the centre consul) when the FAA 'Branniff' modifications were embodied later in the 70's. It's spot got occupied by a standy altimeter mandated by the FAA but this was removed after Branniff ceased flying Concorde; the cabin altimeter returning to it's former home. The REALLY observant will notice that there is neither an Autoland Ca3/Cat2 identifier on the AFCS panel (glued on by BA at LHR) or the famous and precision built 'Reheat Capabilty Indicator' flip down plate fitted to the centre dash panel a few years later by BA.

Also not shown here, as they were buyer furnished equipment also fitted at on delivery LHR, are the two ADEUs (Automatic Data Entry Units, or INS Card readers). These were located immediatel aft of the CDU's and were used for bulk waypoint loading ('bulk' being 9, the most that the poor old Delco INU memory could handle). These were removed in the mid 90's when the Navigation Database was fitted to Concorde INUs, and bulk loading then was achieved by simply tapping in a 2 digit code. (Hardly the elegence of FMS, but still very elegent in comparison with the ADEU's, and worked superbly). A little note about these ADEU things; You inserted this rather large optically read paper data card into the thing and the motor would suck the unsuspecting card in. As often as not the ADEU would chew the card up and spit the remnants out, without reading any data, or not even bother spitting out the remnants at all. Removing these things FINALLY when the INUs were modified was absolute joy!!

ps. When G-BOAG (then G-BFKW) was delivered in 1980 it had neither any of the Branniff mods or ADEUs fitted. (Also the INS was not wired for DME updating). This meant that obviously she could not fly IAD-DFW with Branniff but also she could not do LHR-BAH either, because of the lack ADEUs. (You could not manually insert waypoints quick enough over the 'Med', or so the guys told me. So for the first few years good old FKW/OAG just used to plod between LHR and JFK. And plod she did, superbly. She never did get the ADEUs (not necessary thank goodness when the INUs got modified) but we wired in DME updating and so she could navigate around with the best of them.

My gosh I do prattle on, sorry guys.

Best regards

Dude

PS Welcome back Landlady, hope you've recovered from your fall XXXX

Last edited by M2dude; 15th Jan 2011 at 11:29 .

28th Feb 2011, 23:20

permalink Post: 1221

Quote:

| The first thing I know EXWOK and BELLEROPHON will (maybe) notice is that originally OAD had a 'normal colour' electroluminescent light plate on the visor indication panel. (If I remember rightly (it was a million years ago chaps) when this one 'stopped lighting' we could not get a replacement and had to rob 202 (G-BBDG) at Filton; this one being the same black development aircraft colour that OAD has to this day. |

1st Mar 2011, 23:36

permalink Post: 1226

Quote:

| Just looking at some old 202 pictures Gordon and by golly you are right. Could have sworn it was a 202 (DG) robbery but it obviously it was not. The plot thickens. (I do remember that we had a hell of a job getting hold of this electroluminescent panel for OAD, hence the memory). |

Quote:

| ....which aircraft was it filmed on? |

2nd Mar 2011, 10:08

permalink Post: 1227

G-BOAD's EL panel replacement will just have to remain one of lifes little mysteries.

So the light show was filmed on 202 eh? They were trying out this bilge on the ground on OAB. (Never saw it myself, but that's what was being said in 2001/2002). Obviously the light show is a recent addition to the G-BBDG itinery. Thank goodness none of this nonsense found its way onto the operational fleet.

And Coffin Dodger.. I think that you've summed up the general view.... naff indeed.

Best Regards

Dude

So the light show was filmed on 202 eh? They were trying out this bilge on the ground on OAB. (Never saw it myself, but that's what was being said in 2001/2002). Obviously the light show is a recent addition to the G-BBDG itinery. Thank goodness none of this nonsense found its way onto the operational fleet.

And Coffin Dodger.. I think that you've summed up the general view.... naff indeed.

Best Regards

Dude

2nd Mar 2011, 20:48

permalink Post: 1228

Its not used on G-BBDG, we put the LED strips in along one side to see how Naff it looked......and yes....it was really crap!

22nd Apr 2012, 07:45

permalink Post: 1594

Quote:

| OAF was a standard BA machine, except that being younger it (like OAG) didn't have the 'crown area' mods done |

OAF was indeed a true BA aircraft, it title was bought for \xa31000 and 10,000FF, but significant sums ( million+) were then spent to deliver it to the BA spec. BA did fund and purchase it as their 6th Concorde, albeit at a greatly reduced price.

OAG sort of fell into BA's use. They had "bought" it for under \xa3100,000k, with a must sell back clause , before OAF was delivered to give their services resilience while OAC whet back to Filton for repair. During its use it suffered contamination of its hyd systems, so was grounded, before this was repaired the Concrde programme all but shut down and BA held onto the aircraft fully registering it as OAG, initially it had been G-BFKW.

OAG flew for a short while but was eventually grounded, as I understand it mainly for spares recovery, but as it was a million miles aware spec with from the other BA ( cabin was even different) it was a easy choice to make.

When BA acquired all the spares and full access to G-BBDG a decision was made to bring OAG as close to BA spec as possible and be the first to have a new interior on the fleet. OAG was then then launch Concorde in the land our livery and a lot OAF was a standard BA machine, except that being younger it (like OAG) didn't have the 'crown area' mods done the air to air shots from this time are of it in 1985.

Crown area mods...were these not mandated and embodied fleet wide at the 12,000 major?

29th Apr 2012, 19:13

permalink Post: 1617

Quote:

| For some reason I seem to remember a picture of a Concorde Cockpit with four INS sets side by side, was this ever the case or just my imagination ? |

Quote:

| Also, were the INS installed specially developed for Concorde or were they the same as fitted in the B747 for example. |

Quote:

| Finally was GPS updating to the INS position ever developed and installed ? |

Very relevant for the current time: it was a similar INS system that was hashed into the Vulcan to allow it to find the falklands for the blackbuck raids.

18th Oct 2013, 22:40

permalink Post: 1737

Quote:

|

BA was able to make money on Concorde as in positive cash flow. But they were basically given the airplanes. The commercial failure aspect comes from the simple fact that no one wanted them to build any more (what I've heard is that at least one production Concorde was built but never put into service - basically becoming a donor for spares - not sure if that's true).

|

Quote:

| I also suspect it was too much of a point design - it didn't have the range to be useful in the Pacific. |

CONCORDE SST : CONCORDE B

Quote:

If BA (and Air France) honestly thought Concorde was a profit center (rather than brand prestige), they would have wanted more

.

.

|

Quote:

The same thing would have applied to the Boeing SST if it hadn't been cancelled (I knew a guy that worked on the Boeing SST inlet control system - talk about complex

). Cancelling the SST is probably the best thing that ever happened to Boeing - it likely would have bankrupted the company.

). Cancelling the SST is probably the best thing that ever happened to Boeing - it likely would have bankrupted the company.

|

Last edited by DozyWannabe; 18th Oct 2013 at 23:02 .