22nd Aug 2010, 21:04

permalink Post: 73

Quote:

|

I have yet another couple of questions and I hope all you Concorde experts don't mind me taking up your valuable time.

|

And I enjoy answering those questions, if and whenever I can!

Quote:

| As regards fuel burn: was there any difference between each indvidual airframe and if so was it significant enough to be considered when calculating the trip fuel? |

It was one reason why, when Air France withdrew an aircraft from service, Fox Delta was the first one to go.

Also, due to the gradual improvements in production methods, and minor redesign, the last British production Concorde, G-BOAF, was about a ton lighter than the first one (G-BOAC). While the differences weren't huge, they were noticeable.

Quote:

| Also did different engines also have slightly different fuel consumption? |

Quote:

| Whilst on the subject of engines, I just wondered how many were required to keep the BA Concorde fleet flying? What sort of useful life could be expected from the engines? |

According to 'Wikipedia', 67 engines were built, which would mean, in theory , 64 engines for 16 aircraft and 3 spares....

In practice, of course, fewer aircraft flew at any one time, so the statistics are different, but even so, a lot of engine swapping went on over the years.

As to the MTBO, I don't know... it's not my field at all....

23rd Aug 2010, 08:28

permalink Post: 77

Biggles78

This is the minimum Mach number that can be flown with the existing CG. (which would be around 59%). Just as the CG indicator (not shown in this photo) gave minimum and maximum CG for a given Mach number, the Machmeter gave a reciprical indication also). You can also see that as the aircraft is not flying at Vmo any more, being at Mach 2 cruise, that the VSI pointer is now away from the orange and black Vmo bug. At our 'not so coffin corner', now that the aircraft is at maximun alllowable altitude, Vmo would naturaly coincide with Mmo; the orange and black Mmo bug being shown at Mach 2.04. This really superb photo taken by Bellerophon gives a graphic illustration of what the panels looked like at Mach 2. Note that the with the TCAS VSI Concorde retained it's original linear VSI also. (Miust have beeen the only aircraft flying with FOUR VSIs. (The originals had to be retained due to the fact that the autopilot Vert' Speed Mode error was derived from the indicator itself. As far as TCAS goes, R/As werer inhibited above FL300 (on acceleration this would coincide with the aircraft becoming supersonic, and the mfrs would not countenance the aircraft doing extreme manoeuvrs as a result of TCAS RAs at supersonic speeds).

The tail wheel was lowered for all 'normal' gear cycles (not stby lowering of free-fall). It was designed to protect the bottom the nacelles in the case of over-rotation, but in practical terms the thing was a waste of space (and weight) and a simple tail skid (used on the prototypes) would have sufficed. Any time that the tail wheel contacted the ground, it would ALWAYS collapse, damage the tailcone structure and in fact aforded no protection whatsoever. Fortunately these events were EXTREMELY few and far between. The biggest problem with the tail wheel was a major design flaw: On gear retraction the assembly would retract in sequence with the nose and main gear, and as it entered the opening in the tailcone, it would release over-centre locks that were holding the spring-loaded doors open. The doors would then firmly spring shut behind the gear assembly and finish the job. UNFORTUNATELY this was a very poor design; if for any reason one of the two doors had not gone over-centre on the previous gear lowering, it would be struck by the retracting tail wheel gear and cause structural damage to the local skin area, that would have to have a repair done. Unfortunately these events were not quite so rare, and several measures were tried to reduce the chance of this happening. Although not a safety issue, it was an issue that was a total pain. (As a matter of interest, G-BOAC had this happen on one of it's first test flights out of Fairford in 1975).

Nick Thomas

As ChristiaanJ said, the last two BA aircraft WERE lighter than the others, and would be preferred aircraft for certain charters. But that is not to say that any aircraft could not happily do ANY sector. We fortunately had no distorted airframes in the British fleet, so this was never an issue. There was very little spread, regarding fuel consumption between different engines; one of the best parts about the Olympus 593 was that it hade very little performance deterioration with time, it was an amazing piece of kit.

Time on wing for the engines was a real variable. Each engine was built up of modules, each one of these had a seperate life. In the early days of operation, time on wing was quite poor, and MANY engines would be removed on an attrition basis. One of the early failure problem was the fuel vapourisers inside the combustion chamber were failing, taking bits of turbine with it!! A Rolls Royce modification that completely changed the design of the vapouriser not only solved the problem completely, but also increased the performance of the engine. As the engine matured in service time on wing greatly improved, and in service failures became a thing of the past. A 'trend analysis' was done after each protracted supersonic flight, where engine parameters were input into a propiatry RR computer program, that was able to detect step changes in the figures, and if this were the case, more boroscope inspections were carried out. The OLY time on wing was nothing compared to the big fan engines, but the conditions that it operated under bore no comparison. Not really sure about absolute figures on this one Nick, I'll ask one of my Rolls Royce friends and see if I can find a figure.

Quote:

| What is the Yellow Arc on the Mach metre that starts at about M1.12? |

Quote:

| The center rear fuselage gear unit, what was that for? I have seen it deployed on many occasions but I can't for the life of me remember if it was during T/O or LDG however it didn't seem to be extended every time the aeroplane flew. Was this used during loading so she didn't accidently "rotate" at the ramp or to avoid a tailstrike during LDG? I can't imagine an over rotate during T/O. |

Nick Thomas

Quote:

| As regards fuel burn: was there any difference between each indvidual airframe and if so was it significant enough to be considered when calculating the trip fuel? Also did different engines also have slightly different fuel consumption? |

Quote:

| Whilst on the subject of engines, I just wondered how many were required to keep the BA Concorde fleet flying? What sort of useful life could be expected from the engines? |

Last edited by M2dude; 19th Jan 2011 at 13:42 .

24th Aug 2010, 22:49

permalink Post: 101

ChristiaanJ

aaah yes, Max Climb/Max Cruise modes. I'd not forgotten this my friend, I was going to say a few words about that in a future post, but maybe we can do that now. (And I'd love to hear more of your comments on this here too, ChristiaanJ). The intake and autopilot modifications were in a way complimentary it's true, but really dealt with separate problems, at least in my view:

The intake control unit software change (a change to the control law that limited engine N1 as a function of intake local Mach number, Mo, and inlet total temperature, T1) was able to put an absolute limit on aircraft achievable Mach number during Mmo overshoots, but it would not PREVENT Mmo overshoots occurring altogether, it was more of a safety brake. This particular overspeed problem manifested itself well before route proving, and in fact the intake system 'fix' resulted in the Thrust Auto Reduce System being deleted, electronic control boxes and all. The TAR system was fitted on all development aircraft equiped with the digital intake system, and it tried (in vain) to limit extreme Mach overshoots. The production aircraft retained the TAR wiring and locked out circuit breakers, as well as two vacant spaces on the electronic racks. The prime reason for all these efforts were that some of the rapid excessive Mach overshoots quite often drove the intake into surge; the modification to this N1 limiter control enabled engine mass flow to be controlled in such a way that these surges could be prevented during temperature shears. The aircraft Mach limit was an extremely useful fringe benefit.

The AFCS mode change from what was Max Op and Max Op Soft (always loved that name) to Max Climb/Max Cruise was at a stroke able to deal with the regular Mmo overspeeds that kept on occuring during, as you say, the route proving trials of 1975, when British aircraft G-BOAC and the French aircrfraft F-BTSD carried out pre entry into service evaluation flights, SD sadly was the aircraft that was tragically lost at Gonez in July 2000). The Max Climb/Max Cruise AFCS mode combo is a mode like no other that I've personally seen before or since anywhere, (it for instance resulted an elsewhere taboo; an autopilot and an autothrotte working together IN A SPEED MODE).

This problem encountered primarily at lower lattitudes, (for example, G-BOAC doing route proving flights out of Singapore), occurring initially as the aircraft reached Mach 2. It was termed 'the insurmountable problem', but the AFCS designers (such as ChristiaanJ) fortunately did not have 'insurmountable problems' in their vocabulary. The issue was that the aircraft would have been climbing rapidly at Vmo of 530 KTS, with throttles at the gate as usual, At exactly 50,189' we hit what was known as 'the corner point' in the flight envelope, where 530 KTS IAS equated to Mach 2 exactly. Max Op mode would then 'let go' of the Vmo segment, and try and control the aircraft to Mach 2. (As the aircraft climbed, Vmo itself would progreesively decrease in order to equate to Mmo, or 2.04 Mach). But in very cold conditions, the aircraft still 'wanting' to accelerate, and the simple Max Op/Max Op Soft modes just could not cope with gentle pitch changes alone. The problem became even bigger during the cruise/climb when severe temperature shears occured, and routinely regular Mmo exceedences occured. Something had to be done, and something WAS done and how; enter Max Climb/Max Cruise. It was really a classic piece of design, where the aircraft would do the initial supersonic climb in Max Climb mode. This mode itself was relatively simple, in that it was more or less a Vmo -Vc hold mode. That meant that the difference at selection between indicated airspeed, Vc and Vmo would be maintained, with a vernier datum adjust to this being available. In practice this mode was selected pretty much at Vmo, so datum adjusting was not always required. Now comes the clever part; the autothrottle, this would operate in standy mode at this point, just waiting there doing nothing, with the throttles at maximum as before. So the aircraft would now climb as Vmo increased to 530 KTS, and then following a now constant Vmo of 530 KTS until the magic 'corner point' (51, 189' remember). Now all hell would break loose; the mode would automatically change to Max Cruise, the autothrottle would also be automaically selected to Mach Hold mode (initially datumed here to Mach 2) and the throttles would retard, attempting to hold this Mach 2 datum, and the autopilot is commands a 'fly up' signal, over a 20 second lag period to 600'/minute. Now comes an even cleverer (?) part; the autothrottle Mach Hold datum is gradually increased over a 100 second period towards Mach 2.02, and so in stable conditions the throttles would now gradually increase again until they once more reach the maximum limit. At this point, the autothrottles now come out of Mach Hold mode and back into the waiting in the wings standby mode. The autopilot would now cancel it's 600' fly up, demand, returning to a datum of Mach 2. There was a little more complexity built in also, where the difference between the 'commanded' and actual vertical speeds offset the autoplilot Mach 2 datum. This would apply whether the autothrottle had cut in (+600'/min demand) or with the throttles back at maximum (0'/minute demand. A positive climb error tweaked the cruise Mach up slightly, a negative error (eg. in a turn) the converse was true. The effect of all of this complexity was that the aircraft itself could 'scan' until it settled at a point where the throttles could be at maximum, and the speed between Mach 2 and 2.02. On the North Atlantic, with warmer ISA temperatures, there was usually just the initial routine with the autothrottle as you hit the corner point. However at lower lattitudes (eg. LHR BGI) there could be a few initial autothrottle intercepts before things settled down. This whole incredible routine completely took care of the insurmountable problem, a problem that was shown not only to be insurmountable, but was put to bed forever, by people like ChristiaanJ.

I hope that my explanation here does not sound too much like gibberish.

EXWOK

I think you've guessed right as far as my identity goes; it's great that it's not just Concorde pilots I can bore the socks off now

PS. I bet the ex-SEOs LOVED your comments

Dude

aaah yes, Max Climb/Max Cruise modes. I'd not forgotten this my friend, I was going to say a few words about that in a future post, but maybe we can do that now. (And I'd love to hear more of your comments on this here too, ChristiaanJ). The intake and autopilot modifications were in a way complimentary it's true, but really dealt with separate problems, at least in my view:

The intake control unit software change (a change to the control law that limited engine N1 as a function of intake local Mach number, Mo, and inlet total temperature, T1) was able to put an absolute limit on aircraft achievable Mach number during Mmo overshoots, but it would not PREVENT Mmo overshoots occurring altogether, it was more of a safety brake. This particular overspeed problem manifested itself well before route proving, and in fact the intake system 'fix' resulted in the Thrust Auto Reduce System being deleted, electronic control boxes and all. The TAR system was fitted on all development aircraft equiped with the digital intake system, and it tried (in vain) to limit extreme Mach overshoots. The production aircraft retained the TAR wiring and locked out circuit breakers, as well as two vacant spaces on the electronic racks. The prime reason for all these efforts were that some of the rapid excessive Mach overshoots quite often drove the intake into surge; the modification to this N1 limiter control enabled engine mass flow to be controlled in such a way that these surges could be prevented during temperature shears. The aircraft Mach limit was an extremely useful fringe benefit.

The AFCS mode change from what was Max Op and Max Op Soft (always loved that name) to Max Climb/Max Cruise was at a stroke able to deal with the regular Mmo overspeeds that kept on occuring during, as you say, the route proving trials of 1975, when British aircraft G-BOAC and the French aircrfraft F-BTSD carried out pre entry into service evaluation flights, SD sadly was the aircraft that was tragically lost at Gonez in July 2000). The Max Climb/Max Cruise AFCS mode combo is a mode like no other that I've personally seen before or since anywhere, (it for instance resulted an elsewhere taboo; an autopilot and an autothrotte working together IN A SPEED MODE).

This problem encountered primarily at lower lattitudes, (for example, G-BOAC doing route proving flights out of Singapore), occurring initially as the aircraft reached Mach 2. It was termed 'the insurmountable problem', but the AFCS designers (such as ChristiaanJ) fortunately did not have 'insurmountable problems' in their vocabulary. The issue was that the aircraft would have been climbing rapidly at Vmo of 530 KTS, with throttles at the gate as usual, At exactly 50,189' we hit what was known as 'the corner point' in the flight envelope, where 530 KTS IAS equated to Mach 2 exactly. Max Op mode would then 'let go' of the Vmo segment, and try and control the aircraft to Mach 2. (As the aircraft climbed, Vmo itself would progreesively decrease in order to equate to Mmo, or 2.04 Mach). But in very cold conditions, the aircraft still 'wanting' to accelerate, and the simple Max Op/Max Op Soft modes just could not cope with gentle pitch changes alone. The problem became even bigger during the cruise/climb when severe temperature shears occured, and routinely regular Mmo exceedences occured. Something had to be done, and something WAS done and how; enter Max Climb/Max Cruise. It was really a classic piece of design, where the aircraft would do the initial supersonic climb in Max Climb mode. This mode itself was relatively simple, in that it was more or less a Vmo -Vc hold mode. That meant that the difference at selection between indicated airspeed, Vc and Vmo would be maintained, with a vernier datum adjust to this being available. In practice this mode was selected pretty much at Vmo, so datum adjusting was not always required. Now comes the clever part; the autothrottle, this would operate in standy mode at this point, just waiting there doing nothing, with the throttles at maximum as before. So the aircraft would now climb as Vmo increased to 530 KTS, and then following a now constant Vmo of 530 KTS until the magic 'corner point' (51, 189' remember). Now all hell would break loose; the mode would automatically change to Max Cruise, the autothrottle would also be automaically selected to Mach Hold mode (initially datumed here to Mach 2) and the throttles would retard, attempting to hold this Mach 2 datum, and the autopilot is commands a 'fly up' signal, over a 20 second lag period to 600'/minute. Now comes an even cleverer (?) part; the autothrottle Mach Hold datum is gradually increased over a 100 second period towards Mach 2.02, and so in stable conditions the throttles would now gradually increase again until they once more reach the maximum limit. At this point, the autothrottles now come out of Mach Hold mode and back into the waiting in the wings standby mode. The autopilot would now cancel it's 600' fly up, demand, returning to a datum of Mach 2. There was a little more complexity built in also, where the difference between the 'commanded' and actual vertical speeds offset the autoplilot Mach 2 datum. This would apply whether the autothrottle had cut in (+600'/min demand) or with the throttles back at maximum (0'/minute demand. A positive climb error tweaked the cruise Mach up slightly, a negative error (eg. in a turn) the converse was true. The effect of all of this complexity was that the aircraft itself could 'scan' until it settled at a point where the throttles could be at maximum, and the speed between Mach 2 and 2.02. On the North Atlantic, with warmer ISA temperatures, there was usually just the initial routine with the autothrottle as you hit the corner point. However at lower lattitudes (eg. LHR BGI) there could be a few initial autothrottle intercepts before things settled down. This whole incredible routine completely took care of the insurmountable problem, a problem that was shown not only to be insurmountable, but was put to bed forever, by people like ChristiaanJ.

I hope that my explanation here does not sound too much like gibberish.

EXWOK

I think you've guessed right as far as my identity goes; it's great that it's not just Concorde pilots I can bore the socks off now

PS. I bet the ex-SEOs LOVED your comments

Dude

Last edited by M2dude; 25th Aug 2010 at 01:14 . Reason: missed out some info' (sorry)

29th Aug 2010, 22:26

permalink Post: 154

Nick Thomas

You really do have a great selection of queries Nick .

.

Although Concorde was wired for full area navigation, with autotuning nav radio selectors, this was never fully implemented, and the autotuning selectors replaced with fairly conventional units at entry into service. (Although on route proving trials, G-BOAC did fly with the autotuning selectors).

HOWEVER, a really neat 'next best thing' system evolved: Originally the INS's had an optical card reader for inputting waypoints etc. (when 'island dodging' flying supersonic over the Mediterranean, to avoid booming the populous, it was said to be almost impossible to add waypoints quick enough manually). This card reader was really quite poor; when you inserted the card it was a lottery whether it came out of the reader in one piece, or even at all. Eventually a fairly sophisticated system was developed, and the card readers done away with altogether, and a navigation database was added to the INS units. This database would be updated a couple of times a year, and had to be loaded into each of the three units separately, USING A CASSETTE TAPE!!! All the 'normal' collection Concorde of routes were stored in the database, although the INS core memory could still only handle 9 waypoints at a time. (A light flashed when it was time to 'turn the page' and with a simple push of a button the next bank of waypoints were automatically uploaded into INS core memory. DME co-ordinates were also stored, along with the co-sited VOR frequency that had to be manually dialled for that station; ideally the left and right INSs would use two differing DMEs for best accuracy, and INS3 would use the mean. (Another simple button push would nominate and select the DME to be used by the INS). So, when flying within range of a VOR, the INS position would be refined with the co-sited DME slant range, but when flying oceanic, the 3 INSs would 'triple mix' their inertial positions to give a mean position. A 'rogue' INSs position would be rejected by the other two however, so as not to be sent to the moon because of a bad unit.

Rudderrudderrat

Nowhere near as sophisticated as the FMS system on the Tristar as you can see, but it seemed to work absolutely beautifully. (And when the system was DME updating, we even got an indication from an RNAV light, originally fitted for Area Navigation.

Actally there was a problem of sorts, above 900 KTS G/S, the original DELCO INS would generate an error (after all, WHO would ever want to travell at more than 900 KTS; something must be wrong here

?). A special 'supersonic mode' had to be enabled by the way of pin programming in the INS rack, which inhibited this warning.

?). A special 'supersonic mode' had to be enabled by the way of pin programming in the INS rack, which inhibited this warning.

Really glad you are enjoying the ravings of us supersonic nutters.

Dude

You really do have a great selection of queries Nick

.

.

Quote:

| With the radio navigation update was the lat and long of appropiate radio beacons hard wired into the system and then based on the assumed position the nearest beacons would automatically be tuned or did the pilots enter the lat and long of the beacons that they would then manually tune? |

HOWEVER, a really neat 'next best thing' system evolved: Originally the INS's had an optical card reader for inputting waypoints etc. (when 'island dodging' flying supersonic over the Mediterranean, to avoid booming the populous, it was said to be almost impossible to add waypoints quick enough manually). This card reader was really quite poor; when you inserted the card it was a lottery whether it came out of the reader in one piece, or even at all. Eventually a fairly sophisticated system was developed, and the card readers done away with altogether, and a navigation database was added to the INS units. This database would be updated a couple of times a year, and had to be loaded into each of the three units separately, USING A CASSETTE TAPE!!! All the 'normal' collection Concorde of routes were stored in the database, although the INS core memory could still only handle 9 waypoints at a time. (A light flashed when it was time to 'turn the page' and with a simple push of a button the next bank of waypoints were automatically uploaded into INS core memory. DME co-ordinates were also stored, along with the co-sited VOR frequency that had to be manually dialled for that station; ideally the left and right INSs would use two differing DMEs for best accuracy, and INS3 would use the mean. (Another simple button push would nominate and select the DME to be used by the INS). So, when flying within range of a VOR, the INS position would be refined with the co-sited DME slant range, but when flying oceanic, the 3 INSs would 'triple mix' their inertial positions to give a mean position. A 'rogue' INSs position would be rejected by the other two however, so as not to be sent to the moon because of a bad unit.

Rudderrudderrat

Nowhere near as sophisticated as the FMS system on the Tristar as you can see, but it seemed to work absolutely beautifully. (And when the system was DME updating, we even got an indication from an RNAV light, originally fitted for Area Navigation.

Quote:

| Since INS was developed initially for Intercontinental Ballistic Missile Guidance and the Apollo Space programme, I don't think Mach 2 or less was a problem. |

?). A special 'supersonic mode' had to be enabled by the way of pin programming in the INS rack, which inhibited this warning.

?). A special 'supersonic mode' had to be enabled by the way of pin programming in the INS rack, which inhibited this warning.

Really glad you are enjoying the ravings of us supersonic nutters.

Dude

Last edited by M2dude; 30th Aug 2010 at 05:12 .

4th Sep 2010, 10:49

permalink Post: 212

BRIT312

This story is totally hilarious, can't quite get this visual out of my head. ('100 KTS, POWER SET' sounds so boring in comparison).

I never had the good fortune to meet any of the Braniff guys; sounds like there was certainly a character or two there. It really is a pity that their operation never really got a chance to expand into the proposed Pacific Rim service, who knows, it might really have done something.

I never had the good fortune to meet any of the Braniff guys; sounds like there was certainly a character or two there. It really is a pity that their operation never really got a chance to expand into the proposed Pacific Rim service, who knows, it might really have done something.

It's generally known that the BA aircraft were temporarily re-registered to facilitate Braniff's operation out of IAD to DFW; G-BOAA, B, D & E were re-registered from G-BOAA and so on, to G-N94AA etc. Being an older registration, G-BOAC was re-registered as G-N81AC. At IAD, the 'G' part of the registration was covered over, leaving a now perfect 'American' tail number. Only five aircraft were involved in the operation (at the time BA operated just six aircraft, G-BOAF was still at the manufacturers at Filton, and G-BFKW (later to become G-BOAG) was on loan from British Aerospace. In order for the necessary FAA certification, required for operation by a US airline, a modification package were required by the FAA. Some of these modifications seemed a little 'picky' and irrelevant at the time (they still do). However some modifications were certainly not in this category, and quite honestly should have been 'picked up' by the CAA & DGAC during original certification of the aircraft. As an example, if the flying controls had been operating on GREEN or BLUE hydraulics only (due to an indicated spool valve jam) and that particular hydraulic system was subsequently lost, there was originally no automatic switching to select the standby YELLOW system into the flying controls; the controls would have been completely unpowered until a manual selection was made by the pilot. . One of the 'FAA Mods' was to facilitate just that, so if this (extremely unlikely I grant you) scenario had occurred, then YELLOW would automatically been selected into the controls, and at no time would the controls have been in an unpowered state.

The Braniff operation ended in May 1980, due to heavy losses on the subsonic only route, and it's a rather sad irony that aircraft G-BOAF had been modified and reregistered at Filton, from it's original registration of G-BFKX to G-N94AF. Unfortunately the aircraft was delivered to BA in June 1980, one month too late to participate, and prior to delivery it's registration was converted to it's 'normal' British registration; all other aircraft also reverted to original registrations also.

ChristiaanJ

Not really, being the sad b****d that I am, I still remember the Concorde flare law of: h+5h. = 0, so it was fairly easy to work out the programmed descent rates. (I did have to check the final 1.7'/second figure though). The rest I'm afraid is straight out of this sad old memory of mine.

Bellerophon

A brilliant description of the mechanics of final approach. It's so easy for us mere mortals to forget just what an involved and skilled process it was, to fly, and in particular land our totally amazing aircraft.

Dude

Quote:

| Now the F/E had a couple of calls to make prior to V1 relating to how good the engines were performing the most important being at 100 kts, however before we got that far the Braniff F/E stood up in his harness and let out the cry " Gee Whiz look at the son of a bitch go". |

I never had the good fortune to meet any of the Braniff guys; sounds like there was certainly a character or two there. It really is a pity that their operation never really got a chance to expand into the proposed Pacific Rim service, who knows, it might really have done something.

I never had the good fortune to meet any of the Braniff guys; sounds like there was certainly a character or two there. It really is a pity that their operation never really got a chance to expand into the proposed Pacific Rim service, who knows, it might really have done something.

It's generally known that the BA aircraft were temporarily re-registered to facilitate Braniff's operation out of IAD to DFW; G-BOAA, B, D & E were re-registered from G-BOAA and so on, to G-N94AA etc. Being an older registration, G-BOAC was re-registered as G-N81AC. At IAD, the 'G' part of the registration was covered over, leaving a now perfect 'American' tail number. Only five aircraft were involved in the operation (at the time BA operated just six aircraft, G-BOAF was still at the manufacturers at Filton, and G-BFKW (later to become G-BOAG) was on loan from British Aerospace. In order for the necessary FAA certification, required for operation by a US airline, a modification package were required by the FAA. Some of these modifications seemed a little 'picky' and irrelevant at the time (they still do). However some modifications were certainly not in this category, and quite honestly should have been 'picked up' by the CAA & DGAC during original certification of the aircraft. As an example, if the flying controls had been operating on GREEN or BLUE hydraulics only (due to an indicated spool valve jam) and that particular hydraulic system was subsequently lost, there was originally no automatic switching to select the standby YELLOW system into the flying controls; the controls would have been completely unpowered until a manual selection was made by the pilot. . One of the 'FAA Mods' was to facilitate just that, so if this (extremely unlikely I grant you) scenario had occurred, then YELLOW would automatically been selected into the controls, and at no time would the controls have been in an unpowered state.

The Braniff operation ended in May 1980, due to heavy losses on the subsonic only route, and it's a rather sad irony that aircraft G-BOAF had been modified and reregistered at Filton, from it's original registration of G-BFKX to G-N94AF. Unfortunately the aircraft was delivered to BA in June 1980, one month too late to participate, and prior to delivery it's registration was converted to it's 'normal' British registration; all other aircraft also reverted to original registrations also.

ChristiaanJ

Quote:

| Reading your description of the autoland, you must be quoting from documentation, no? |

Bellerophon

A brilliant description of the mechanics of final approach. It's so easy for us mere mortals to forget just what an involved and skilled process it was, to fly, and in particular land our totally amazing aircraft.

Dude

Last edited by M2dude; 4th Sep 2010 at 13:12 .

11th Sep 2010, 16:32

permalink Post: 317

Quote:

|

One of my Scout Leaders, back in the sixties, was involved in (I think) programming the milling machines that milled Concorde wing panels from solid alloy billets. Dural I assume, I didn't think there was much Titanium in Concorde?

|

The first production Concorde (204, G-BOAC) was about a ton heavier than the last on (216, G-BOAF). IIRC most of that was achieved by judicious use of titanium in certain locations.

The aluminium alloy was not Dural, but a special alloy called RR58, AU2GN or hiduminium which was used because of its superior 'creep' properties ('creep' = slow permanent deformation under a combination of mechanical stress and high temperatures).

Quote:

| How much of the Lady's structure was machined from the solid like this? |

(As an example of the latter, ever looked at a photo of the top of the wing of a Concorde with all those oval-shaped access panels? They were all machined.

Quote:

In one sense, it seems extremely wasteful, but in another it is the most perfect way of "knocking off everything that doesn't look like a wing panel." To paraphrase someone.

|

It also made for greater precision and repeatablity, more consistent quality, etc.

And the scrap from the milling operation was recovered and recycled....

CJ

13th Sep 2010, 13:23

permalink Post: 341

I was Googling to see if I could find some info on how the CG indicator on Concorde functioned and found the following two links. The first one is an AAIB report from 2003 regarding a minor fire aboard G-BOAC whilst in transatlantic cruise which resulted in misreadings and failure flags on fuel guages. The second one is from the PPRuNe archives also dated 2003.

The last two comments at the bottom of that old PPRuNe thread are interesting since as evidenced by this ongoing thread (as well as the others running in the tech forum), seven years later, many many people are still fascinated by this gorgeous aircraft.

http://www.aaib.gov.uk/cms_resources...pdf_029047.pdf

http://www.pprune.org/archive/index.php/t-109948.html

The last two comments at the bottom of that old PPRuNe thread are interesting since as evidenced by this ongoing thread (as well as the others running in the tech forum), seven years later, many many people are still fascinated by this gorgeous aircraft.

http://www.aaib.gov.uk/cms_resources...pdf_029047.pdf

http://www.pprune.org/archive/index.php/t-109948.html

27th Oct 2010, 22:33

permalink Post: 616

Mike-Bracknell

It is not nonsense, and you are quite at liberty to post here. Wow, that's still quite a question though Mike. There are two TECHNICAL issues that overshadow all others, namely airframe corrosion and hydraulic system deterioration. Unfortunately none of the BA aircraft were stored inside from the outset, so we have a real issue here as far as corrosion goes, plus all the hydraulic systems were drained, resulting in seal drying out and probable moisture ingress into the 3 systems. But given sufficient funds (and assuming you find an organisation to take over design responsibility from Airbus;

ironic when you consider that without Concorde there would almost certainly have been no such organisation

) there is still no technical reason why the problems (and there are dozens of other problems to consider) could not be overcome, the money side of things is another matter

Looking first at the French fleet, the main candidate for restoration to flight status would be F-BTSD at Le Bourget. Not only has this aircraft been lovingly cared for and stored INSIDE, but the aircraft has had several systems (including the Green hydraulic system) powered and reservoirs not drained.

The British story is less clear; G-BOAA in East Fortune was effectively killed when the wings were cut off for transportation, so that one is out of the question. G-BOAB, the last and only Concorde at LHR has been left to rot outside, in fact holes were even drill in the fuselage to drain water, so this one is a no no too. G-BOAC at Manchester, now the oldest surviving production aircraft was initially stored outside, but now resides in a purpose built exhibition 'hangar'. Now she COULD be a potential candidate for consideration; when I last saw her just over a year ago she was absolutely pristine; a testament to the team that have been caring for her there. G-BOAD, stored next to the USS Intrepid in New York, we can probably forget, due to having been exposed to 7 years worth of salt water corrosion from the Hudson River. (Also, while she was temporarily stored in New Jersey a couple of years ago, some IDIOT in a truck bent the whole nose section when he hit her. The radome was smashed (replaced with a rather clever fibreglass fabrication) and the nose straightened with a blow-torch and hammer (I am not joking!!). G-BOAE at Grantley Adams airport in Barbados has been stored under cover for much of the time; provided she has not suffered too much from the wam damp atmosphere of Barbados, well she could be a potential candiitate too. G-BOAF in Filton, well PROVIDED she is still OK after her 'removal from public view' experience could also be a potential candidate also. And finally, G-BOAG in Seattle; well she had been left outside, right next to a highway (and close to a truck stop too). She did not look too good the last time I saw her; the undercarriage barrels werer all brown and discoloured and the paintwork was completely dull and matte. (She had a new paint job not too long before retirement too). So out of the 'BA Seven', I PERSONALLY would go for G-BOAF, G-BOAC or G-BOAG.

As I have said often here before, it is EXTREMELY unlikely that what you, Mike, suggest will ever happen, but in spite of what others might say, IT IS NOT IMPOSSIBLE. My own gut feeling is a resounding 'no', but I could be wrong, . (And NO ONE would be happier than I if I am wrong; I was with the BA aircraft through construction, flight testing and the entire service life with BA).

As for the cost? It really is a case of 'how long is a piece of string', but for 2 aircraft we could be looking in excess of $100 or more, who knows?

But as the Everly Brothers used to sing 'All I have to do is dream.'

Keep posting Mike.

Dude .

.

Quote:

| IF funding were secured to get 1 Concorde from each fleet into the air again, which one out of each fleet would be the easiest to return to service, given what has gone on since retirement? Also, a subpoint, does anyone have any finger-in-the-air figures as to how much cost it would take and whether there's any fundamental issues that would need to be sorted aside from the airworthiness certificate etc. |

Looking first at the French fleet, the main candidate for restoration to flight status would be F-BTSD at Le Bourget. Not only has this aircraft been lovingly cared for and stored INSIDE, but the aircraft has had several systems (including the Green hydraulic system) powered and reservoirs not drained.

The British story is less clear; G-BOAA in East Fortune was effectively killed when the wings were cut off for transportation, so that one is out of the question. G-BOAB, the last and only Concorde at LHR has been left to rot outside, in fact holes were even drill in the fuselage to drain water, so this one is a no no too. G-BOAC at Manchester, now the oldest surviving production aircraft was initially stored outside, but now resides in a purpose built exhibition 'hangar'. Now she COULD be a potential candidate for consideration; when I last saw her just over a year ago she was absolutely pristine; a testament to the team that have been caring for her there. G-BOAD, stored next to the USS Intrepid in New York, we can probably forget, due to having been exposed to 7 years worth of salt water corrosion from the Hudson River. (Also, while she was temporarily stored in New Jersey a couple of years ago, some IDIOT in a truck bent the whole nose section when he hit her. The radome was smashed (replaced with a rather clever fibreglass fabrication) and the nose straightened with a blow-torch and hammer (I am not joking!!). G-BOAE at Grantley Adams airport in Barbados has been stored under cover for much of the time; provided she has not suffered too much from the wam damp atmosphere of Barbados, well she could be a potential candiitate too. G-BOAF in Filton, well PROVIDED she is still OK after her 'removal from public view' experience could also be a potential candidate also. And finally, G-BOAG in Seattle; well she had been left outside, right next to a highway (and close to a truck stop too). She did not look too good the last time I saw her; the undercarriage barrels werer all brown and discoloured and the paintwork was completely dull and matte. (She had a new paint job not too long before retirement too). So out of the 'BA Seven', I PERSONALLY would go for G-BOAF, G-BOAC or G-BOAG.

As I have said often here before, it is EXTREMELY unlikely that what you, Mike, suggest will ever happen, but in spite of what others might say, IT IS NOT IMPOSSIBLE. My own gut feeling is a resounding 'no', but I could be wrong, . (And NO ONE would be happier than I if I am wrong; I was with the BA aircraft through construction, flight testing and the entire service life with BA).

As for the cost? It really is a case of 'how long is a piece of string', but for 2 aircraft we could be looking in excess of $100 or more, who knows?

But as the Everly Brothers used to sing 'All I have to do is dream.'

Keep posting Mike.

Dude

.

.

2nd Nov 2010, 02:41

permalink Post: 651

I've been following this fantastic thread since day 1 - what a tremendous source of information and inspiration!

Was fortunate to have a look around G-BOAC in Manchester today, and she's being looked after extremely well. There are a few photos here if anybody would like to take a look... and I'm more than happy to share them so feel free to download if you wish.

MobileMe Gallery

Thanks for a truly fantastic thread, all!

Was fortunate to have a look around G-BOAC in Manchester today, and she's being looked after extremely well. There are a few photos here if anybody would like to take a look... and I'm more than happy to share them so feel free to download if you wish.

MobileMe Gallery

Thanks for a truly fantastic thread, all!

Last edited by Pax-man; 2nd Nov 2010 at 13:20 .

20th Nov 2010, 02:16

permalink Post: 744

M2 Dude

Back in August of 1997 I had the privilege of a ride in G-BOAC out of CYYZ on a flight to now where ie east of JFK up to FL550 Mach 2.0 etc.

It was back in a gentler day with a visit to the flight deck and I can still remember it all is if it was yesterday. As you can tell by web name I am industry and I really appreciated the short time I had in the Flight Deck. Unfortuneatly I was one of 99 that day so I did not get a chance to ask all the questions but the fuel system and fuel pump mini lecture from the flight engineer was stunning.

Please accept my sincere thank you and to Christian as well.

Like the Avro Arrow the TSR-2 the Concorde will live long in our minds.

One last comment many years ago we were number 2 on 09R in LHR and Concorde takes off in front of us. We were in an L-1011 that day and it shook as if a metal saw was trying to cut us in two. The Flight Service Director came running in white as a ghost and his first words were "What the #@&*" was that.........................

Please keep writing your story and if I ever run across you on the other side of the "pond" the bitter is on me

Back in August of 1997 I had the privilege of a ride in G-BOAC out of CYYZ on a flight to now where ie east of JFK up to FL550 Mach 2.0 etc.

It was back in a gentler day with a visit to the flight deck and I can still remember it all is if it was yesterday. As you can tell by web name I am industry and I really appreciated the short time I had in the Flight Deck. Unfortuneatly I was one of 99 that day so I did not get a chance to ask all the questions but the fuel system and fuel pump mini lecture from the flight engineer was stunning.

Please accept my sincere thank you and to Christian as well.

Like the Avro Arrow the TSR-2 the Concorde will live long in our minds.

One last comment many years ago we were number 2 on 09R in LHR and Concorde takes off in front of us. We were in an L-1011 that day and it shook as if a metal saw was trying to cut us in two. The Flight Service Director came running in white as a ghost and his first words were "What the #@&*" was that.........................

Please keep writing your story and if I ever run across you on the other side of the "pond" the bitter is on me

29th Nov 2010, 07:18

permalink Post: 805

Dozy Wannabe

I am afraid it is a case of 'go figure'. Recent history (as well as what is going on right now) shows that there is little interest in even caring for the aeroplane at Filton, let alone preserving her. Who built what is not the point here anyway.. When design and construction of the aircraft was carried out there were TWO airframe companies, A\xe9rospatiale and BAC. Now we just have Airbus, with virtually zero British input now. (Don't get me wrong, this is the fault of the British and not the French, we are the ones that threw everything away). I can not explain the attitude of Airbus to the aeroplane, it just remains a cold hard fact.... THEY ARE NOT INTERESTED

INTERESTED

We are all well aware that the disposal of the aircraft was the decision of the airlines thank you, I did know that. Now like it or not, there really is a lot of anger behind the fact that no INTACT British aircraft has been stored under cover from the beginning, and only one of those aircraft in the UK itself is stored away from the elements. G-BOAC the oldest production Concorde in the world, is beautifully preserved and cared for in Manchester, which makes a hell of a contrast to G-BOAF, the YOUNGEST Concorde in the world at Filton. I am really sorry if all this discord saddens you, it pleases none of us I'm sure, but truth is often like that I'm afraid, we have to deal with it; a national disgrace.

Now like it or not, there really is a lot of anger behind the fact that no INTACT British aircraft has been stored under cover from the beginning, and only one of those aircraft in the UK itself is stored away from the elements. G-BOAC the oldest production Concorde in the world, is beautifully preserved and cared for in Manchester, which makes a hell of a contrast to G-BOAF, the YOUNGEST Concorde in the world at Filton. I am really sorry if all this discord saddens you, it pleases none of us I'm sure, but truth is often like that I'm afraid, we have to deal with it; a national disgrace.

There is also no point avoiding this truth as far as the ceasation of services goes, just because when you unravel the duplicity and deceit behind the happenings of 2003, you discover a sense of disgust and outrage on the part of the British Concorde community. Far from 'not making a blind bit of difference' it makes a huge amount of difference to where we are. I do agree that we should concentrate on celebrating this truly wonderful national icon (I do so every day), but we must not be afraid of looking at the history that has got us (the aeroplane) in the sorry state we are now.

Regards

Dude

I am afraid it is a case of 'go figure'. Recent history (as well as what is going on right now) shows that there is little interest in even caring for the aeroplane at Filton, let alone preserving her. Who built what is not the point here anyway.. When design and construction of the aircraft was carried out there were TWO airframe companies, A\xe9rospatiale and BAC. Now we just have Airbus, with virtually zero British input now. (Don't get me wrong, this is the fault of the British and not the French, we are the ones that threw everything away). I can not explain the attitude of Airbus to the aeroplane, it just remains a cold hard fact.... THEY ARE NOT

INTERESTED

INTERESTED

We are all well aware that the disposal of the aircraft was the decision of the airlines thank you, I did know that.

Now like it or not, there really is a lot of anger behind the fact that no INTACT British aircraft has been stored under cover from the beginning, and only one of those aircraft in the UK itself is stored away from the elements. G-BOAC the oldest production Concorde in the world, is beautifully preserved and cared for in Manchester, which makes a hell of a contrast to G-BOAF, the YOUNGEST Concorde in the world at Filton. I am really sorry if all this discord saddens you, it pleases none of us I'm sure, but truth is often like that I'm afraid, we have to deal with it; a national disgrace.

Now like it or not, there really is a lot of anger behind the fact that no INTACT British aircraft has been stored under cover from the beginning, and only one of those aircraft in the UK itself is stored away from the elements. G-BOAC the oldest production Concorde in the world, is beautifully preserved and cared for in Manchester, which makes a hell of a contrast to G-BOAF, the YOUNGEST Concorde in the world at Filton. I am really sorry if all this discord saddens you, it pleases none of us I'm sure, but truth is often like that I'm afraid, we have to deal with it; a national disgrace.

There is also no point avoiding this truth as far as the ceasation of services goes, just because when you unravel the duplicity and deceit behind the happenings of 2003, you discover a sense of disgust and outrage on the part of the British Concorde community. Far from 'not making a blind bit of difference' it makes a huge amount of difference to where we are. I do agree that we should concentrate on celebrating this truly wonderful national icon (I do so every day), but we must not be afraid of looking at the history that has got us (the aeroplane) in the sorry state we are now.

Regards

Dude

Last edited by M2dude; 29th Nov 2010 at 13:09 .

30th Dec 2010, 09:50

permalink Post: 1049

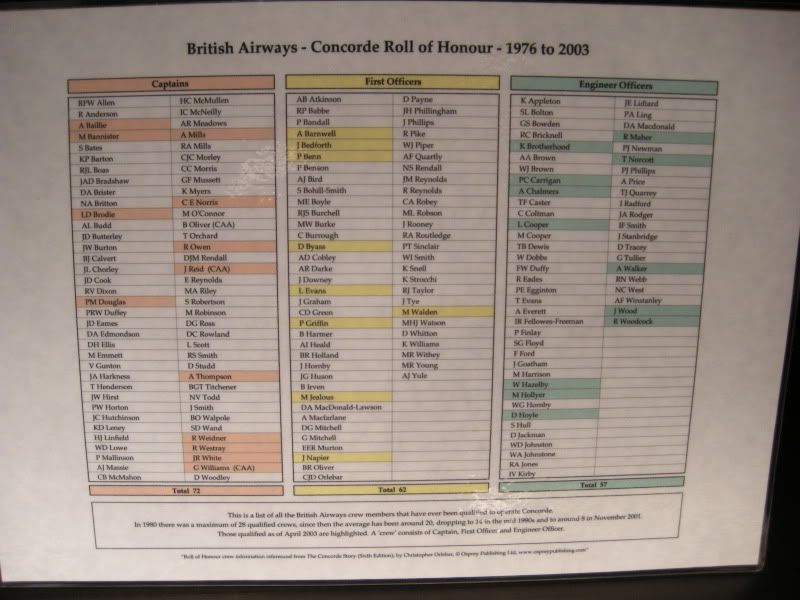

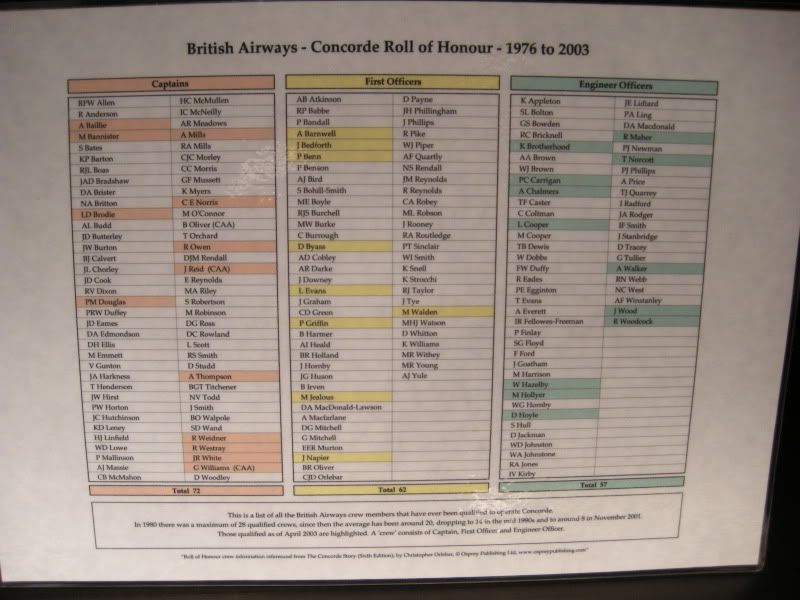

BA Crew List

Firstly a very big thank you to all who have made this the best read of the decade.

In response to both Christiaan and Brit312 posts, here is the role of honour proudly on display inside G-BOAC at Manchester.

Regards

Andy

In response to both Christiaan and Brit312 posts, here is the role of honour proudly on display inside G-BOAC at Manchester.

Regards

Andy

30th Dec 2010, 14:00

permalink Post: 1050

Bell Inn Charter

Quote:

|

Peronally, I still remember vaguely there's a tale of the customers of a country pub somewhere in England actually chartering a Concorde for a "round-the-bay" flight, but I've never been able to find the full story.

CJ |

A little bit of further digging on this trip has revealed ..

"Brian Calvert was a pilot on the very first commercial Concorde flight, and a regular at The Bell Inn. Ian Macaulay asked whether it would be possible to take a trip on it and Brian made it possible to arrange. As a result, on 19th September 1978 one hundred people paid \xa3100 each to make the first ever chartered flight in the supersonic airliner."

I wonder how many drinks it took them to convince Brian Calvert it would be a good idea

There is also a reference to Concorde in the Aldworth Millennium Tapestry that was made in 1999 showing. Aldworth Millennium Tapestry

I am very lucky to live only 30 miles from G-BOAC and have made several visits including doing the technical tours - although nothing like the detail that I have learnt from yourselves

In response to Christiaan's question about how the technical tours were done in comparision to F-BTSD at Le Bourget, unfortunatley it only looks like lighting power is supplied to the A/C - no hydraulics seem to be 'left intact' and working which is a huge shame.

For me it only shows that 'she' (or 'he'

) is a very special entity that did prove to be so much more than just a 'machine'. Even though she isn't flying, you still catch yourself standing in awe each time you see her. at first I wasn't sure about AC's new 'hangar', but apart from keeping her dry, I must admit it does add atmosphere to the occasion.

) is a very special entity that did prove to be so much more than just a 'machine'. Even though she isn't flying, you still catch yourself standing in awe each time you see her. at first I wasn't sure about AC's new 'hangar', but apart from keeping her dry, I must admit it does add atmosphere to the occasion.

Cheers

Andy

13th Jan 2011, 20:23

permalink Post: 1087

If you look at it from straight ahead it's not really a 'kink'.

From the angle the 'kinky' photo was taken the outer sweep of the ogee wing is towards the camera before sweeping aft to the drooped and washed-out tips and it looks like a kink in the LE sweep. The actual shape is seen better in the picture above. I've spent hours studying our G-BOAC at Manchester and to me the wing is a complex and lovely blend of curves and slopes, with no sudden changes such as a kink would require. Standing under the wing and observing it closely, no kink is apparent.

The wash-out on the tips shows particularly well in the above photo (washout is a forward twist of the wing at the tips to reduce the angle of attack of the tips compared to the rest of the wing, to prevent tip-stalling).

A question I have, relating to the photo above, is about the LE. The LE definately 'droops' in the area ahead of the intakes (it doesn't do so nearer the roots or tips). Is this to provoke a clean flow-breakaway in this area at high angles of attack to encourage the votices to form at this point as the wing transitions to vortex lift?

M2Dude Thanks for the kind words and careful explanations. I take it from your description of the anti-skid that once the mains start to rotate the brakes can be used, as the anti-skid comes 'off' (mains no longer think they are skidding).

I thought there was protection to prevent brake use until the nose wheels have landed, else brake application with the nose high would cause a rapid nose-down pitch, slamming the nosewheels on! Is there any such protection?

From the angle the 'kinky' photo was taken the outer sweep of the ogee wing is towards the camera before sweeping aft to the drooped and washed-out tips and it looks like a kink in the LE sweep. The actual shape is seen better in the picture above. I've spent hours studying our G-BOAC at Manchester and to me the wing is a complex and lovely blend of curves and slopes, with no sudden changes such as a kink would require. Standing under the wing and observing it closely, no kink is apparent.

The wash-out on the tips shows particularly well in the above photo (washout is a forward twist of the wing at the tips to reduce the angle of attack of the tips compared to the rest of the wing, to prevent tip-stalling).

A question I have, relating to the photo above, is about the LE. The LE definately 'droops' in the area ahead of the intakes (it doesn't do so nearer the roots or tips). Is this to provoke a clean flow-breakaway in this area at high angles of attack to encourage the votices to form at this point as the wing transitions to vortex lift?

M2Dude Thanks for the kind words and careful explanations. I take it from your description of the anti-skid that once the mains start to rotate the brakes can be used, as the anti-skid comes 'off' (mains no longer think they are skidding).

I thought there was protection to prevent brake use until the nose wheels have landed, else brake application with the nose high would cause a rapid nose-down pitch, slamming the nosewheels on! Is there any such protection?

Last edited by Shaggy Sheep Driver; 13th Jan 2011 at 21:41 .

28th Jan 2011, 22:19

permalink Post: 1148

Quote:

|

Static ports are by no means unique to Concorde; all aeroplanes have them. They measure the air pressure around the aeroplane, and this value is used in various aspects of aircraft instrumentation. In particular, it is used (together with the dynamic pressure value) to display indicated air speed.

|

When passing Mach 1, the nose shock wave moves rearwards, and passes over the static ports.

As a result, there is a "twitch" on both the altimeter (barely visible) and on the VSI (verical speed indicator, very visible) when exceeding Mach 1.

Quote:

| By the way - engine bay doors; we open one on OAC for our Technical Tours (not the shorter, 'Classic', tours where there wouldn't be time) so we can show the 593 Olympus and tell our visitors about it. Those doors certainly are heavy! |

People on another (French) forum were asking about the engines on G-BOAC...

Are they still all in place? Or were any dropped for display outside the aircraft?

CJ

29th Jan 2011, 17:12

permalink Post: 1149

All 4 engines (and indeed everything else that BA left untouched on de-commission) are still in the airframe. She is pretty much as she was when she flew in on 31st October 2003.

Here is the only OAC engine bay pic I have. Must remember to take my camera next time I do a tour!

G-BOAC engine no. 1.

Here is the only OAC engine bay pic I have. Must remember to take my camera next time I do a tour!

G-BOAC engine no. 1.

Last edited by Shaggy Sheep Driver; 29th Jan 2011 at 17:25 .

30th Jan 2011, 10:38

permalink Post: 1154

Pen Pusher

That really is a superb photo and shows just what a large but cramped affair the Concorde engine bay was. Although a pre-producion example, the picture generally shows what the production aircraft looked like inside the chasm. In the picture you can see the titanium roof of the engine bay that did such a good job in protecting the wing above (as was the case with the OAF engine failure in 1980 mentioned previously in this thread). What is missing from the 101s engine bay shown here are the air conditioning primary and secondary heat exchangers that were fitted above the engines. (The large trunking you can see coming forward from the jet pipes are the exhausts for the ram air from the exchangers). On a blunty, the heat exhangers are mounted in the belly of the aircraft, in what is generally known as a pack. But there was no room in Concorde for such lumpy bits, and so the only alternative was to mount them above the engine. The remainder of the equipment, the Cold Air Unit (or Air Cycle Machine as the blunties call them) as well as the, unique to Concorde, Fuel heat exchanger were mounted in the wings. With everything so sprawled about it could not really be called a 'pack' and so in Concorde we refered to an air conditioning GROUP.

The wiring you can see on the lower parts of the engine doors is generally Graviner fire wire, used for engine fire and nacelle overheat detection. At the forward part of the 2 doors (shown most clearly on the #4 engine) are two orange 'boxes. These are the engine bay ventilation 'ground running flap' electrical actuators (the flaps themselves being shown shut). Normally these spring loaded flaps would be open on the ground, being progreesively closed with increasing speed as engine bay pressure increased. The actuator would only run when the engine fire handle was pulled, to help seal off the bay. All the other orange stuff you can see is FTD, or flight teast wiring and equiment. (We used to not very kindly refer to it as 'orange s--t' ).

).

With regard to aircraft 204, G-BOAC I think you will find that all the engines are still installed. I took this photo (oops sorry, my wife did ) when we had a function in Manchester about 18 months ago. You can see what a wonderful job the folk up there are doing taking care of her, and as for dining under the wing.. it was truly a memorable experience indeed.

) when we had a function in Manchester about 18 months ago. You can see what a wonderful job the folk up there are doing taking care of her, and as for dining under the wing.. it was truly a memorable experience indeed.

Best regards

Dude

That really is a superb photo and shows just what a large but cramped affair the Concorde engine bay was. Although a pre-producion example, the picture generally shows what the production aircraft looked like inside the chasm. In the picture you can see the titanium roof of the engine bay that did such a good job in protecting the wing above (as was the case with the OAF engine failure in 1980 mentioned previously in this thread). What is missing from the 101s engine bay shown here are the air conditioning primary and secondary heat exchangers that were fitted above the engines. (The large trunking you can see coming forward from the jet pipes are the exhausts for the ram air from the exchangers). On a blunty, the heat exhangers are mounted in the belly of the aircraft, in what is generally known as a pack. But there was no room in Concorde for such lumpy bits, and so the only alternative was to mount them above the engine. The remainder of the equipment, the Cold Air Unit (or Air Cycle Machine as the blunties call them) as well as the, unique to Concorde, Fuel heat exchanger were mounted in the wings. With everything so sprawled about it could not really be called a 'pack' and so in Concorde we refered to an air conditioning GROUP.

The wiring you can see on the lower parts of the engine doors is generally Graviner fire wire, used for engine fire and nacelle overheat detection. At the forward part of the 2 doors (shown most clearly on the #4 engine) are two orange 'boxes. These are the engine bay ventilation 'ground running flap' electrical actuators (the flaps themselves being shown shut). Normally these spring loaded flaps would be open on the ground, being progreesively closed with increasing speed as engine bay pressure increased. The actuator would only run when the engine fire handle was pulled, to help seal off the bay. All the other orange stuff you can see is FTD, or flight teast wiring and equiment. (We used to not very kindly refer to it as 'orange s--t'

).

).

With regard to aircraft 204, G-BOAC I think you will find that all the engines are still installed. I took this photo (oops sorry, my wife did

) when we had a function in Manchester about 18 months ago. You can see what a wonderful job the folk up there are doing taking care of her, and as for dining under the wing.. it was truly a memorable experience indeed.

) when we had a function in Manchester about 18 months ago. You can see what a wonderful job the folk up there are doing taking care of her, and as for dining under the wing.. it was truly a memorable experience indeed.

Best regards

Dude

30th Jan 2011, 14:25

permalink Post: 1158

Olympus Picture

SSD wrote:

is there something missing dead centre of the picture ?? to the Left of what I presume is a an FCU on the Gearbox? Looks to be a V-Band clamp still there hanging on the pad ??

Also I heard of a similar test on the RB199; ran it up on a test bed to full power and let it stabilise for a few minutes, drain the Lube Oil Tank and stand back to see what happens - 24 hours later they gave up as it was still running !!

Possibly a standard RR development test ?

regards

Howie

Quote:

| G-BOAC engine no. 1. |

Also I heard of a similar test on the RB199; ran it up on a test bed to full power and let it stabilise for a few minutes, drain the Lube Oil Tank and stand back to see what happens - 24 hours later they gave up as it was still running !!

Possibly a standard RR development test ?

regards

Howie

30th Jan 2011, 14:45

permalink Post: 1159

The 'blind' window is where the wardrobes are - no seats there. Also just about visible in that picture is the 'area ruling' of the rear fuselage where the fin starts - the fuselage is noticeably 'waisted' there.

Glad you enjoyed the event at 204, Dude. I have a lovely painting on my wall of G-BOAC on the roll-out on her last ever landing at EGCC 31st October 2003. It was signed all around the border by all the Concorde crews present that evening that I could cajole into signing, then I got it framed!

Glad you enjoyed the event at 204, Dude. I have a lovely painting on my wall of G-BOAC on the roll-out on her last ever landing at EGCC 31st October 2003. It was signed all around the border by all the Concorde crews present that evening that I could cajole into signing, then I got it framed!

8th Feb 2011, 05:51

permalink Post: 1178

I worked on the project for eighteen months in production design control at Brooklands. We were to facilitate certification by the CAA and BEA (Fr).

We built the enlarged tail cone tank and the "droop Snoop" and fwd. fuselage.

I recall that one of the biggest design problems was the toilet up the front.

There simply wasn't the space.

Sir George Edwards fired most of us prior to to the first revenue flight of G-BOAC out of Heathrow.

I got a job at BP in Meadhurst and enjoyed listening and watching this beautiful aircraft get airbourne for New York from the roof of the research establishment that day.

I only played a small part but by God it was fun.

I am looking at my office wall in Fremantle, Western Australia at a photograph of G-BOAC after getting airbourne on its maiden flight. It is signed by my work golleges at Brooklands.

Somewhere in a trunk I have a copy (blueprint) of prototype 01 notated in both English and French. (I cannot recall how I came by it).

This is the best thread I have read ever. What a machine !!

The spin parachute and emergency escape hatch are interesting

We built the enlarged tail cone tank and the "droop Snoop" and fwd. fuselage.

I recall that one of the biggest design problems was the toilet up the front.

There simply wasn't the space.

Sir George Edwards fired most of us prior to to the first revenue flight of G-BOAC out of Heathrow.

I got a job at BP in Meadhurst and enjoyed listening and watching this beautiful aircraft get airbourne for New York from the roof of the research establishment that day.

I only played a small part but by God it was fun.

I am looking at my office wall in Fremantle, Western Australia at a photograph of G-BOAC after getting airbourne on its maiden flight. It is signed by my work golleges at Brooklands.

Somewhere in a trunk I have a copy (blueprint) of prototype 01 notated in both English and French. (I cannot recall how I came by it).

This is the best thread I have read ever. What a machine !!

The spin parachute and emergency escape hatch are interesting