20th Aug 2010, 12:06

permalink Post: 34

Biggles78

I know these fuel flows seem crazy (If take-off fuel flows had been maintained the endurance of the aircraft would have been about 55 minutes!!). But as the majority of the flight was carried out at Mach 2 and above, with the relatively miniscule fuel flows, you can see how we were able to cross the Atlantic with relative ease. It was the subsonic bit that was the pain.

The powerplant was as you say truly amazing. We had an, as yet, unmatched engine/intake combination, with a variable primary and secondary nozzles. The variable intake allowed supersonic operation with maximum pressure recovery, minimum aerodynamic drag, as well as extreme operational stability. (Extreme temperature shears, that would have caused surge/unstarts in military installations) were dealt with as a total non event). It's astonishing to believe, but at Mach 2 cruise, the intake provided approximately 63% of the powerplant thrust. It was controlled by the world's first airborne digital control system. (The system computers were built by the Guided Weapons Division of what was then BAC). The combination of the variable intake, plus the LP and HP compressors gave an overall compression ratio of 80:1.

The engine itself, being supplied with air at an ideal pressure, could run at an almost conststant TET, thanks to the variable primary nozzle. This also allowed N1 and N2 (corrected for total temperature) to be controlled more or less independently and run as close as possible to their separate surge lines throughout the entire flight envelope.

The variable secondary nozzle (wide open above Mach 1.1) allowed the jet efflux to gently expand against a cushion of air that was passed over the rear ramp of the intake, through the engine bay and into the annulus of the nozzle itself. This prevented thrust being wasted by the jet efflux widely splaying as it met ambient air that was at a pressure of as little as 1.04 PSIA.

It was this integrated powerplant that made true supersonic cruise possible

The airframe life issue was sort of like 'how long is a piece of string?'. The airframes are lifed in supersonic cycles, (which had been extended before, with modifications) and studies were always underway as far as further life extensions were concerned. (Basically the airframe was as tough as a brick outhouse in structural terms). The only real area of concern was the crown area (the roof

). There was a design flaw here in that the structure had not been designed fail-safe (allegedly by designed a Korean designer at A\xe9rospatiale who, it was said, went a bit loopy). When the FAA evaluated the design (in order for the aircraft to be registered in the USA, for Braniff operations out of IAD) they wanted 'crown planking' to be fitted externally, which would have added over a tonne to the weight of the aircraft, as well as producing some not inconsiderable drag. Fortunately a compromise was reached and additional NDT inspections were carried out, as well as more limited structural modifications. There was a long term, cost effective solution being studied, which would have cured the problem altogether. (The changes would have been mandated, over new requirements for ageing aircraft)

). There was a design flaw here in that the structure had not been designed fail-safe (allegedly by designed a Korean designer at A\xe9rospatiale who, it was said, went a bit loopy). When the FAA evaluated the design (in order for the aircraft to be registered in the USA, for Braniff operations out of IAD) they wanted 'crown planking' to be fitted externally, which would have added over a tonne to the weight of the aircraft, as well as producing some not inconsiderable drag. Fortunately a compromise was reached and additional NDT inspections were carried out, as well as more limited structural modifications. There was a long term, cost effective solution being studied, which would have cured the problem altogether. (The changes would have been mandated, over new requirements for ageing aircraft)

Nick Thomas

Nick, the whole expansion issue was one of the biggest issues that had to be addressed. Wiring looms would 'snake' in some underfllor areas to take up expansion, but the biggest difficulty of all were the mulitudes of hydraulic lines. These required sliding expansion joints, with of course seals to prevent leakage. When a seal deteriorated YPU GOT A LEAK!! (Fluid at 4000 PSI tends torun for freedom very quickly ). As far as fittings go, ChristiaanJ is quite right, you tried to anchor at one end only. I seem to remember that the passenger seat rails travelled over a roller afair. Fuel lines wer less of a problem, because their relative lengths were less.

). As far as fittings go, ChristiaanJ is quite right, you tried to anchor at one end only. I seem to remember that the passenger seat rails travelled over a roller afair. Fuel lines wer less of a problem, because their relative lengths were less.

I also agree wholeheartedly with ChristiaansJ's explanation about the 'friction' thing, I never really liked those stories. As a matter of interest, 127 deg's, for Mach 2, that would be at ISA +5 (-51.5 deg's C). Any warmer than that and we could not achieve Mach 2, due to the Tmo limit of 127. I remember one year, for several weeks we had unusually high north Atlantic temperatures; these impacted both the flight time AND the fuel burn. The further away you were from Mach 2, the higher the fuel consumption. (The faster you flew, the less fuel you burnt. How's that for a paradox?).

At ISA (-56.5 deg's C) temperatures, the total temperature was at around 118 deg's C.

ChristiaanJ

I remember the 17.5 degree position on the nose; it always looked as if the aircraft was trying to eat ants to me . I can not recall personally anyone removing the 12.5 deg' stops for access, although this could of course have been done on your side of the 'puddle' I guess.

. I can not recall personally anyone removing the 12.5 deg' stops for access, although this could of course have been done on your side of the 'puddle' I guess.

As far as the APU ducting issue goes (hee, hee, not often we disagree Christiaan ) we are just going to have to agree to disagee about this, although I accept that two 4" diameter pipes (PLUS THERMAL INSULATION) might have done it, BUT I still stand by the other points.

) we are just going to have to agree to disagee about this, although I accept that two 4" diameter pipes (PLUS THERMAL INSULATION) might have done it, BUT I still stand by the other points.

Stlton

Unfortunately not; the keel beam area was extremely thin and there was not anywhere near enough room. Interesting solution on the 727 though, I never knew that one.

Quote:

Mate, if you could have seen my jaw drop when I read the T/O burn you would probably hurt yourself laughing to much. That is just incredible but the cruise flow seems like stuff all especially considering the speed. The idle flow was also a bit of a jaw dropper.

|

Quote:

| Was surprised, yet again, that Mach 2 was achieved without reheat. They really were/are an amazing powerplant. |

The engine itself, being supplied with air at an ideal pressure, could run at an almost conststant TET, thanks to the variable primary nozzle. This also allowed N1 and N2 (corrected for total temperature) to be controlled more or less independently and run as close as possible to their separate surge lines throughout the entire flight envelope.

The variable secondary nozzle (wide open above Mach 1.1) allowed the jet efflux to gently expand against a cushion of air that was passed over the rear ramp of the intake, through the engine bay and into the annulus of the nozzle itself. This prevented thrust being wasted by the jet efflux widely splaying as it met ambient air that was at a pressure of as little as 1.04 PSIA.

It was this integrated powerplant that made true supersonic cruise possible

Quote:

| On my list of regrets, not getting a flight on Concorde would be in the top 5. If they hadn't grounded them what sort of life did the airframes have left in them? |

). There was a design flaw here in that the structure had not been designed fail-safe (allegedly by designed a Korean designer at A\xe9rospatiale who, it was said, went a bit loopy). When the FAA evaluated the design (in order for the aircraft to be registered in the USA, for Braniff operations out of IAD) they wanted 'crown planking' to be fitted externally, which would have added over a tonne to the weight of the aircraft, as well as producing some not inconsiderable drag. Fortunately a compromise was reached and additional NDT inspections were carried out, as well as more limited structural modifications. There was a long term, cost effective solution being studied, which would have cured the problem altogether. (The changes would have been mandated, over new requirements for ageing aircraft)

). There was a design flaw here in that the structure had not been designed fail-safe (allegedly by designed a Korean designer at A\xe9rospatiale who, it was said, went a bit loopy). When the FAA evaluated the design (in order for the aircraft to be registered in the USA, for Braniff operations out of IAD) they wanted 'crown planking' to be fitted externally, which would have added over a tonne to the weight of the aircraft, as well as producing some not inconsiderable drag. Fortunately a compromise was reached and additional NDT inspections were carried out, as well as more limited structural modifications. There was a long term, cost effective solution being studied, which would have cured the problem altogether. (The changes would have been mandated, over new requirements for ageing aircraft)

Nick Thomas

Nick, the whole expansion issue was one of the biggest issues that had to be addressed. Wiring looms would 'snake' in some underfllor areas to take up expansion, but the biggest difficulty of all were the mulitudes of hydraulic lines. These required sliding expansion joints, with of course seals to prevent leakage. When a seal deteriorated YPU GOT A LEAK!! (Fluid at 4000 PSI tends torun for freedom very quickly

). As far as fittings go, ChristiaanJ is quite right, you tried to anchor at one end only. I seem to remember that the passenger seat rails travelled over a roller afair. Fuel lines wer less of a problem, because their relative lengths were less.

). As far as fittings go, ChristiaanJ is quite right, you tried to anchor at one end only. I seem to remember that the passenger seat rails travelled over a roller afair. Fuel lines wer less of a problem, because their relative lengths were less.

I also agree wholeheartedly with ChristiaansJ's explanation about the 'friction' thing, I never really liked those stories. As a matter of interest, 127 deg's, for Mach 2, that would be at ISA +5 (-51.5 deg's C). Any warmer than that and we could not achieve Mach 2, due to the Tmo limit of 127. I remember one year, for several weeks we had unusually high north Atlantic temperatures; these impacted both the flight time AND the fuel burn. The further away you were from Mach 2, the higher the fuel consumption. (The faster you flew, the less fuel you burnt. How's that for a paradox?).

At ISA (-56.5 deg's C) temperatures, the total temperature was at around 118 deg's C.

ChristiaanJ

I remember the 17.5 degree position on the nose; it always looked as if the aircraft was trying to eat ants to me

. I can not recall personally anyone removing the 12.5 deg' stops for access, although this could of course have been done on your side of the 'puddle' I guess.

. I can not recall personally anyone removing the 12.5 deg' stops for access, although this could of course have been done on your side of the 'puddle' I guess.

As far as the APU ducting issue goes (hee, hee, not often we disagree Christiaan

) we are just going to have to agree to disagee about this, although I accept that two 4" diameter pipes (PLUS THERMAL INSULATION) might have done it, BUT I still stand by the other points.

) we are just going to have to agree to disagee about this, although I accept that two 4" diameter pipes (PLUS THERMAL INSULATION) might have done it, BUT I still stand by the other points.

Stlton

Quote:

|

Not to beat a dead horse, but, on the choice of location for APU, the 727 had a problem with this but for different reasons. Because of the location of the engines that were all mounted at the rear, the Aircraft was quite tail heavy and adding more weight with an APU in the tail section was not desirable.The solution found that I have not seen in any other Aircraft was to mount it in the wheel well transversely across the keel beam with the exhaust out and over the right wing. Quite unusual but it worked fine with the restriction that it could only be operated on the ground.

Its all academic now but, just out of curiosity could this have worked on the Concorde |

25th Aug 2010, 14:39

permalink Post: 111

I have been been on PPRuNe for 10 years now, and this is one of the most fascinating threads I've ever read. Some of the quotes give me goosebumps:

And to think that she was designed in the 1960s by men with slide rules and drawing boards. How fitting that the most sophisticated airliner ever built was also by far and away the most beautiful.

Some years ago I had the privilege of meeting Capt. David Rowland (he of the ITVV video fame) at a GAPAN aptitude test day, and it is one of my cherished memories. I recall we spent about 30 seconds discussing my test results, and the remaining 10 minutes chatting about Concorde . . .

Please keep the memories coming guys \x96 as a humble Dash 8 driver, I will always be in awe of the technological marvel which was Concorde.

Quote:

| this fuel system really was a study in elegance. |

Quote:

| On test flights however, the aircraft would routinely zoom climb to FL 630 . . . . . . the highest recorded Concorde altitude was on one of the French development aircraft, which achieved 68,000'. |

Quote:

| The powerplant was as you say truly amazing. We had an, as yet, unmatched engine/intake combination, with a variable primary and secondary nozzles. The variable intake allowed supersonic operation with maximum pressure recovery, minimum aerodynamic drag, as well as extreme operational stability. (Extreme temperature shears, that would have caused surge/unstarts in military installations) were dealt with as a total non event). It's astonishing to believe, but at Mach 2 cruise, the intake provided approximately 63% of the powerplant thrust. It was controlled by the world's first airborne digital control system. |

Quote:

| We never had a case of lost pressurisation, ever. |

Quote:

| the aircraft handled beautifully through an 1100kt speed range. |

Some years ago I had the privilege of meeting Capt. David Rowland (he of the ITVV video fame) at a GAPAN aptitude test day, and it is one of my cherished memories. I recall we spent about 30 seconds discussing my test results, and the remaining 10 minutes chatting about Concorde . . .

Please keep the memories coming guys \x96 as a humble Dash 8 driver, I will always be in awe of the technological marvel which was Concorde.

31st Aug 2010, 21:44

permalink Post: 172

Quote:

|

Originally Posted by

DozyWannabe

Well, it was essentially a development airframe pressed into premature service for the sake of beating a western project into the air.

|

Quote:

|

Good point I suppose, but you could say that the six Concorde prototypes, Pre-Production and Production Series Test aircraft were also development aircraft

|

Wherever you look... the cockpit, the visor, the engines, the tail, the avionics, other systems... the prototypes were a first "iteration", designed and built to prove the concept.

The real development was done on what were the real "development aircraft", the pre-production and first two production aircraft (even if 01 / G-AXDN was a bit of a hybrid, retaining the short tail and the early engine nozzles).

I hope sometime the story; of how different were 001 and 002 from those that followed, will go on record before it fades into the mists of time.

CJ

5th Sep 2010, 02:37

permalink Post: 216

Question for engineering types:

I remember being told in my conversion course that the motors driving the secondary nozzles (buckets) were the fastest rotating devices on the aircraft. Is it true? Have you got a number for it? Was it really more than the gyro in the stby horizon?

If anyone has seen the video of AF landing at BZZ after the first post-grounding test flight, you may have noticed that you can hear the buckets translating to reverse even over the noise of the blustery wind and four Olympus 593's at idle.

I remember being told in my conversion course that the motors driving the secondary nozzles (buckets) were the fastest rotating devices on the aircraft. Is it true? Have you got a number for it? Was it really more than the gyro in the stby horizon?

If anyone has seen the video of AF landing at BZZ after the first post-grounding test flight, you may have noticed that you can hear the buckets translating to reverse even over the noise of the blustery wind and four Olympus 593's at idle.

5th Sep 2010, 11:56

permalink Post: 217

Capt Chambo

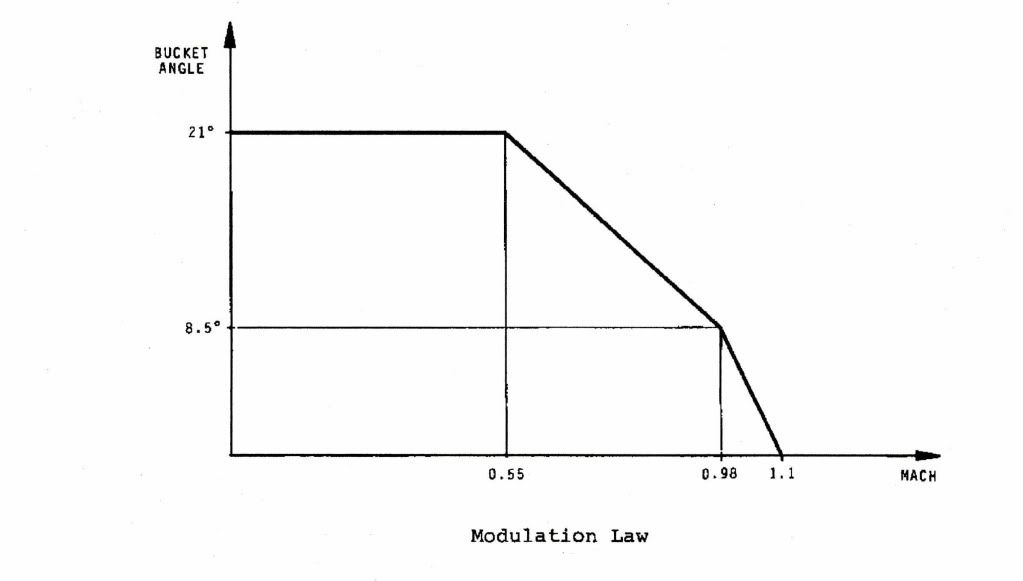

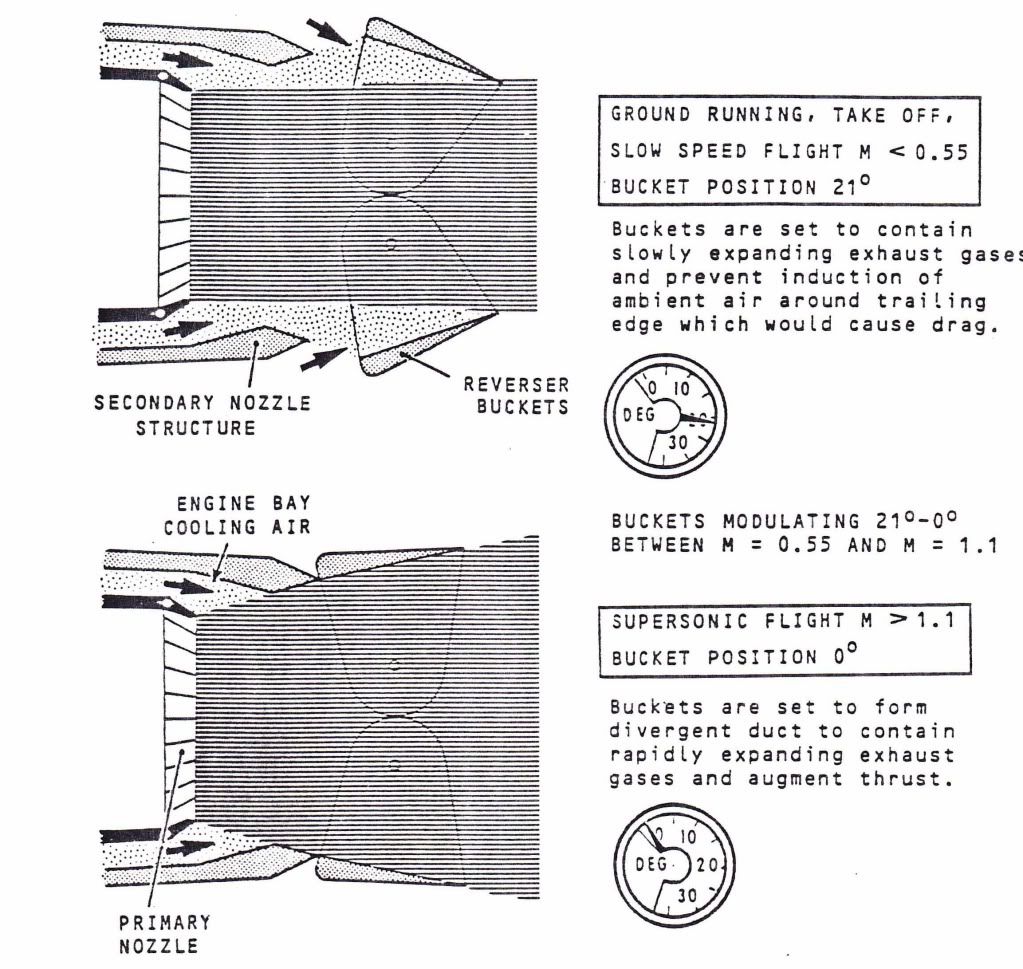

Concorde was, as EXWOK says, could use reverse in flight, on the inboard engines only, and only as far as reverse idle, the mechanism of which was quite complex and did on occasion not do work as advertised. Bear in mind here that the Rolls Royce Olympus 593 was a pure turbojet with no bypass, and so a hot stream reverser only had to be used; the reverser buckets acting directly on the efflux as it did any reverser in the 'old' days. Also the same buckets that were used for reverse were also progressively opened up between Mach 0.55 and wide open at Mach 1.1, this giving a vital control enhancement to the divergencing efflux. The overall effect of this was to give a true overall convergent/divergent nozzle assembly, the ideal for any supersonic aircraft.

As far as inflight reverse goes, the amount of HP compressor delivery air (P3) required to actuate the bucket airmotor in flight at an idle thrust settings, was quite minimal to say the least, and some help was definitely needed here. The moment that inflight reverse was selected (on the inboard engines only remember) the OUTBOARD engines would have their idle N2 automatically increased, and some of THEIR P3 air supply was also automatically ported over (via an isolation valve) to the inboard buckets. This whole process was required in order to give a little added muscle to the bucket airmotors, and give the system a fighting chance. Even this however was still not quite enough, the inboard travelling buckets required minimal air loading on their surface, and so the primary nozzles for the affected engines (the primary nozzle lived just aft of the LP turbine, aft of the reheat assembly) was automatically signalled wide open in order to assist matters here, by reducing gas velocity. One the buckets had reached full reverse the primary nozzle was then signalled full close (this applied for normal ground reverse also) and the automatic increased idle on the outboard engines was cancelled. To enable the described process to occur, provided all four engines were at idle, a solenoid latched button on the F/E's station could be selected. This signalled a circuit that enabled the selection of idle reverse on the inboard engines only, the opening of the P3 isolation valve, the raising of the outboard engine's idle and maximum primary nozzle angle for the outboards as soon as reverse was then selected..

The whole system was just a little fragile here; failure of either the extra air supply, or the raised idle on the 'other' engine was usually enough to stop the process working correctly.

EXWOK

While flying 'up front' I only ever experienced the use of inflight reverse once. (The captain was a bit of an Animal, if you flying guys see what I mean ). I would not say that it felt as if we'd hit a brick wall, as I'd expected the sensation to feel, more like we were flying into the dumped contents of a very large manure truck

). I would not say that it felt as if we'd hit a brick wall, as I'd expected the sensation to feel, more like we were flying into the dumped contents of a very large manure truck

. The whole operation was so slick, we'd dumped the required amount of IAS more or less within a second or two, and normal thrust was immediately selected. As so often happened with you guys, you made it look too easy.

. The whole operation was so slick, we'd dumped the required amount of IAS more or less within a second or two, and normal thrust was immediately selected. As so often happened with you guys, you made it look too easy.

As far as the speed of the airmotor goes, I seem to remember that it was something in the order of 80,000 RPM at max chat; as you say faster (around twice as fast) as the standby horizon motor.

The basic core airmotor (not the whole assembly) was the same Garrett unit used on the P&W JT9 as well as the RB-211.

Dude

Concorde was, as EXWOK says, could use reverse in flight, on the inboard engines only, and only as far as reverse idle, the mechanism of which was quite complex and did on occasion not do work as advertised. Bear in mind here that the Rolls Royce Olympus 593 was a pure turbojet with no bypass, and so a hot stream reverser only had to be used; the reverser buckets acting directly on the efflux as it did any reverser in the 'old' days. Also the same buckets that were used for reverse were also progressively opened up between Mach 0.55 and wide open at Mach 1.1, this giving a vital control enhancement to the divergencing efflux. The overall effect of this was to give a true overall convergent/divergent nozzle assembly, the ideal for any supersonic aircraft.

As far as inflight reverse goes, the amount of HP compressor delivery air (P3) required to actuate the bucket airmotor in flight at an idle thrust settings, was quite minimal to say the least, and some help was definitely needed here. The moment that inflight reverse was selected (on the inboard engines only remember) the OUTBOARD engines would have their idle N2 automatically increased, and some of THEIR P3 air supply was also automatically ported over (via an isolation valve) to the inboard buckets. This whole process was required in order to give a little added muscle to the bucket airmotors, and give the system a fighting chance. Even this however was still not quite enough, the inboard travelling buckets required minimal air loading on their surface, and so the primary nozzles for the affected engines (the primary nozzle lived just aft of the LP turbine, aft of the reheat assembly) was automatically signalled wide open in order to assist matters here, by reducing gas velocity. One the buckets had reached full reverse the primary nozzle was then signalled full close (this applied for normal ground reverse also) and the automatic increased idle on the outboard engines was cancelled. To enable the described process to occur, provided all four engines were at idle, a solenoid latched button on the F/E's station could be selected. This signalled a circuit that enabled the selection of idle reverse on the inboard engines only, the opening of the P3 isolation valve, the raising of the outboard engine's idle and maximum primary nozzle angle for the outboards as soon as reverse was then selected..

The whole system was just a little fragile here; failure of either the extra air supply, or the raised idle on the 'other' engine was usually enough to stop the process working correctly.

EXWOK

While flying 'up front' I only ever experienced the use of inflight reverse once. (The captain was a bit of an Animal, if you flying guys see what I mean

). I would not say that it felt as if we'd hit a brick wall, as I'd expected the sensation to feel, more like we were flying into the dumped contents of a very large manure truck

). I would not say that it felt as if we'd hit a brick wall, as I'd expected the sensation to feel, more like we were flying into the dumped contents of a very large manure truck

. The whole operation was so slick, we'd dumped the required amount of IAS more or less within a second or two, and normal thrust was immediately selected. As so often happened with you guys, you made it look too easy.

. The whole operation was so slick, we'd dumped the required amount of IAS more or less within a second or two, and normal thrust was immediately selected. As so often happened with you guys, you made it look too easy.

As far as the speed of the airmotor goes, I seem to remember that it was something in the order of 80,000 RPM at max chat; as you say faster (around twice as fast) as the standby horizon motor.

The basic core airmotor (not the whole assembly) was the same Garrett unit used on the P&W JT9 as well as the RB-211.

Dude

Last edited by M2dude; 5th Sep 2010 at 13:25 .

7th Sep 2010, 08:39

permalink Post: 250

I hope this one is interesting; it's a Rolls Royce diagram illustrating what the wildly varying differences were in terms of the engine between take off and supersonic cruise. The primary nozzle can be seen at the rear of the engine, together with the reheat assembly and the secondary nozzle (reverser buckets).

Yes ChristaanJ, I FINALLY managed to upload stuff here.

Yes ChristaanJ, I FINALLY managed to upload stuff here.

8th Sep 2010, 14:04

permalink Post: 279

Of course! That's what this thread is about !

Two answers.

Only the first three Concordes (001, 002 and 01) had a real tail skid (coated with hardwood, IIRC, to prvent sparks).

From aircraft 02 onwards, the skid was replaced by two small wheels, that look as if they've come off a Spitfire....

To understand why it's there, look at a drawing of a side view of Concorde.

If a Concorde overrotates at take-off, or lands with the nose too high, the first things that would have touched the ground are the exhaust nozzles / thrust reverser buckets. The tail skid/wheels are there to prevent that.

As to the need for it...

"Tailstrikes" were rare, but they did happen.

Now I don't remember offhand whether it was already mentioned here or somewhere else, but more often than not those tail wheels were not much good, and got shoved back into the tail, with the reverser buckets still hitting the ground : there are photos of repairs to the buckets to prove it !

CJ

Quote:

| I noticed a tail skid in many videos. Did Concorde ever have a need for it? |

Only the first three Concordes (001, 002 and 01) had a real tail skid (coated with hardwood, IIRC, to prvent sparks).

From aircraft 02 onwards, the skid was replaced by two small wheels, that look as if they've come off a Spitfire....

To understand why it's there, look at a drawing of a side view of Concorde.

If a Concorde overrotates at take-off, or lands with the nose too high, the first things that would have touched the ground are the exhaust nozzles / thrust reverser buckets. The tail skid/wheels are there to prevent that.

As to the need for it...

"Tailstrikes" were rare, but they did happen.

Now I don't remember offhand whether it was already mentioned here or somewhere else, but more often than not those tail wheels were not much good, and got shoved back into the tail, with the reverser buckets still hitting the ground : there are photos of repairs to the buckets to prove it !

CJ

7th Oct 2010, 04:02

permalink Post: 522

Oshkosh 1994

One very long winded piece of personal nostalgia, I hope you\x92ll all bear with me:

In 1994 a Concorde (can\x92t remember the registration) flew out to Oshkosh Wisconsin (OKS) for the bi-annual EAA fly in. The aircraft was scheduled to fly from LHR to YYZ via MAN, where it would pick up 100 charter passengers in Manchester for a five day holiday in Toronto. The aircraft would then fly empty from YYZ to Oshkosh for the five day air show, before returning to YYZ to bring home the passengers to MAN. At Manchester another 100 charter passengers were then carried subsonically back to London. While the aircraft was in Canada and the US, it would be looked after by two American BA engineers who were based at JFK. At least that was the plan, but the best laid plans of mice and men\x85.

The aircraft was catered for the MAN-YYZ sector in London, and flew up to Manchester with just the three flight deck crew but no cabin crew (no passengers, so no need). At Manchester there would be a change of crew, plus a full complement of cabin crew for the on-going sector to Toronto (Plus of course 100 passengers). This is where things started to go rather wrong; when the aircraft landed at Manchester one of the bar trolleys , which had not been correctly secured by the catering twits, broke loose and flew through the open flight deck door (pre-911 the door was usually always open anyway). The trolley hit the back of the E/O\x92s chair and subsequently damaged a couple of fuel transfer switches on his panel. You can imagine what the three crew thought; they were just landing the aircraft when a high speed trolley decides to join them on the flight deck in an extremely noisy and spectacular entrance. (The language went something like \x91what the ***** was that!!). The two switches, although damaged still operated normally, and so the crew taking the aircraft to YYZ decided to accept the aircraft with just a couple of ADDs for the broken but still funtional switches.

So the aircraft, plus FOUR flight crew (an extra crew member, a captain in this case, was taken along to do the PR over the PA, as was usual on charter operations). Everything seemed to be going smoothly, or so it seemed, when there was a warning that the number 2 secondary nozzle \x91buckets\x92 had travelled towards reverse (the blue transit light was flashing) although the indicator on the E/O\x92s panel still apparently showed the nozzle at the correct zero degree position for supersonic flight. As always (at least with BA!!) the correct drill was applied, and a precautionary engine shut down was carried out. This now meant that the aircraft would have to decelerate to subsonic speed, and as a consequence would not be able to reach YYZ safely, and so a technical diversion to YQX (Gander NFLD) was carried out, the aircraft and passengers having an unscheduled night stop there. (This eating into the first night of the passengers stay in Toronto). The two JFK engineers who had been waiting patiently in YYZ had to quickly jump on a Lear Jet to Gander, and on arrival there got on the phone to London, that\x92s where I come in. The nozzle itself had not run away at all, it was merely an indication problem, but we all decided that the best course of action for now was to have the secondary nozzle physically locked at the intermediate position of 10 degrees as a performance ADD. This would still allow supersonic operation (although from YQX to YYZ there would be precious little of that), but with a fuel penalty of at least 1.5 tonnes per supersonic sector, plus of course no reverser operation on that engine. I still had concerns about the aircraft being able to return on the YYZ to MAN sector with a bucket locked out, but at least the passengers could now start their delayed holiday in Toronto, and the aircraft could happily fly on to the wilds of Wisconsin.

Every day during the EAA fly in, Concorde would do some charter flying, and the JFK guys would be on the phone every day letting us know how things were going. It seemed now that the secondary nozzle defect had \x91cleared up\x92 on it\x92s own, and the guys had decided to reinstate the secondary nozzle air motor to its normal position. We were all very apprehensive about this, and started to think about what the possible cause of the original defect was and maybe see about provisioning a spare part if necessary. On the final day of the EAA event, the aircraft was taxying out when another warning light for the number 2 bucket illuminated. The aircraft returned to the ramp where the JFK engineers again locked out the air motor at 10 degrees before leaving on its charter. We had discussions over the phone as to what the symptoms were, and it looked like the culprit was the switch pack that lived underneath the bucket assembly. I spent several hours getting spare parts shipped via MAINTROL to YYZ, the idea being that the bits could be flown out to Toronto on the next scheduled subsonic flight. It was generally agreed that the aircraft could not fly the YYZ-MAN sector with a bucket locked out due to performance considerations and so a fix was essential. (The spare parts included by the way the two switches that had been broken on the first landing into Manchester).

I was at the airport until quite late that night making sure that from the information that we\x92d been given the correct course of action had been chosen, and I only got about four hours of sleep before I had to head back to Heathrow the following morning. I had a feeling that I\x92d be possibly be asked to fly out to Toronto (the JFK guys requested this also) , so I took my passport, a change of clothes etc. with me just in case. Sure enough before I knew it I was on the 10:30 BA001 Concorde to JFK, a Limo taking me immediately across town from JFK to La Guardia. From there I was put on an Air Canada A320 to Toronto, arriving there at about 14:30 local time. (19:30 \x91my\x92 time, I was knackered already). When I got to our Concorde the JFK guys told me that the bits I\x92d sent the previous evening were stuck in Canadian Customs, and it took another hour or so to get our hands on them. We proceeded to get her \x91fixed up\x92 between us, and by about 20:00 local we were serviceable. I phoned the crew at the hotel, telling them of the good news, and was told that as soon as I\x92d checked in and had a shower, we were all going out to dinner (my body clock was now at 02:00). Now the flight crew and cabin crew are well [FONT='Calibri','sans-serif']acclimatised, having been in Canada and the States for FIVE days, but I am now a total wreck, (more so than usual), and w hen I finally got to bed it was around midnight Toronto time (05:00 London time). Now no one (including me) expected to see me for the 07:30 pick up from the hotel in the morning, but somehow I miraculously made it. Because one passenger had gone home to Manchester early, there was a seat available for me on the aircraft (I\x92d expected to have had to fly home subsonic, due to the only other available seat being the flip down flight deck aisle seat; to have sat there for over four hours would have been less than pleasant). So all I now wanted to do was get on the aircraft, collapse into my seat and SLEEP, but I had to wait until all passengers had boarded before I was allocated my seat; 26B right at the back of the aircraft. So here I go, getting onto the aircraft in what I thought was total anonymity when as I get on board the purser in the fwd. galley announces that \x91this is Mr Dude who flew out yesterday from London especially to make sure we don\x92t have to divert again\x92. I just wanted to die as I have to walk the gauntlet of 99 passengers all clapping and cheering all the way to the back of the aircraft, my face as red as a beetroot, and when I finally get to my seat I find that I am sat next to this really lovely elderly lady who wanted a blow by blow account of what had gone on, as well as a running commentary on the flight itself. (Of course alll I wanted to do was sleep, I was totally exhausted, but this old lady was absolutely delightful). About an hour after take-off one of the stewardesses informs me that the crew want me up front urgently, so here I go again walking the length of the cabin up to the flight deck. As I go in the guys said \x91I thought you\x92d fixed the *** ing thing.\x92 \x91I did\x92 replies yours truly, and I took a look at the flight deck panels and everything is normal. The four guys are killing themselves laughing, \x91fooled you\x92 , the flight engineer chirps up with (everything was fine, the joke was on me yet again). I once more stagger back to my seat, and for the rest of the flight I keep my lady passenger friend entertained with Concorde stories all the way back to Manchester. At Manchester there is another few hours wait before we FINALLY fly back down to Heathrow, with yet another load of passengers and I finally go home to bed. In all of my Concorde years I\x92d had many exhausting episodes, but Toronto \x9294 really took the biscuit.

Dude

In 1994 a Concorde (can\x92t remember the registration) flew out to Oshkosh Wisconsin (OKS) for the bi-annual EAA fly in. The aircraft was scheduled to fly from LHR to YYZ via MAN, where it would pick up 100 charter passengers in Manchester for a five day holiday in Toronto. The aircraft would then fly empty from YYZ to Oshkosh for the five day air show, before returning to YYZ to bring home the passengers to MAN. At Manchester another 100 charter passengers were then carried subsonically back to London. While the aircraft was in Canada and the US, it would be looked after by two American BA engineers who were based at JFK. At least that was the plan, but the best laid plans of mice and men\x85.

The aircraft was catered for the MAN-YYZ sector in London, and flew up to Manchester with just the three flight deck crew but no cabin crew (no passengers, so no need). At Manchester there would be a change of crew, plus a full complement of cabin crew for the on-going sector to Toronto (Plus of course 100 passengers). This is where things started to go rather wrong; when the aircraft landed at Manchester one of the bar trolleys , which had not been correctly secured by the catering twits, broke loose and flew through the open flight deck door (pre-911 the door was usually always open anyway). The trolley hit the back of the E/O\x92s chair and subsequently damaged a couple of fuel transfer switches on his panel. You can imagine what the three crew thought; they were just landing the aircraft when a high speed trolley decides to join them on the flight deck in an extremely noisy and spectacular entrance. (The language went something like \x91what the ***** was that!!). The two switches, although damaged still operated normally, and so the crew taking the aircraft to YYZ decided to accept the aircraft with just a couple of ADDs for the broken but still funtional switches.

So the aircraft, plus FOUR flight crew (an extra crew member, a captain in this case, was taken along to do the PR over the PA, as was usual on charter operations). Everything seemed to be going smoothly, or so it seemed, when there was a warning that the number 2 secondary nozzle \x91buckets\x92 had travelled towards reverse (the blue transit light was flashing) although the indicator on the E/O\x92s panel still apparently showed the nozzle at the correct zero degree position for supersonic flight. As always (at least with BA!!) the correct drill was applied, and a precautionary engine shut down was carried out. This now meant that the aircraft would have to decelerate to subsonic speed, and as a consequence would not be able to reach YYZ safely, and so a technical diversion to YQX (Gander NFLD) was carried out, the aircraft and passengers having an unscheduled night stop there. (This eating into the first night of the passengers stay in Toronto). The two JFK engineers who had been waiting patiently in YYZ had to quickly jump on a Lear Jet to Gander, and on arrival there got on the phone to London, that\x92s where I come in. The nozzle itself had not run away at all, it was merely an indication problem, but we all decided that the best course of action for now was to have the secondary nozzle physically locked at the intermediate position of 10 degrees as a performance ADD. This would still allow supersonic operation (although from YQX to YYZ there would be precious little of that), but with a fuel penalty of at least 1.5 tonnes per supersonic sector, plus of course no reverser operation on that engine. I still had concerns about the aircraft being able to return on the YYZ to MAN sector with a bucket locked out, but at least the passengers could now start their delayed holiday in Toronto, and the aircraft could happily fly on to the wilds of Wisconsin.

Every day during the EAA fly in, Concorde would do some charter flying, and the JFK guys would be on the phone every day letting us know how things were going. It seemed now that the secondary nozzle defect had \x91cleared up\x92 on it\x92s own, and the guys had decided to reinstate the secondary nozzle air motor to its normal position. We were all very apprehensive about this, and started to think about what the possible cause of the original defect was and maybe see about provisioning a spare part if necessary. On the final day of the EAA event, the aircraft was taxying out when another warning light for the number 2 bucket illuminated. The aircraft returned to the ramp where the JFK engineers again locked out the air motor at 10 degrees before leaving on its charter. We had discussions over the phone as to what the symptoms were, and it looked like the culprit was the switch pack that lived underneath the bucket assembly. I spent several hours getting spare parts shipped via MAINTROL to YYZ, the idea being that the bits could be flown out to Toronto on the next scheduled subsonic flight. It was generally agreed that the aircraft could not fly the YYZ-MAN sector with a bucket locked out due to performance considerations and so a fix was essential. (The spare parts included by the way the two switches that had been broken on the first landing into Manchester).

I was at the airport until quite late that night making sure that from the information that we\x92d been given the correct course of action had been chosen, and I only got about four hours of sleep before I had to head back to Heathrow the following morning. I had a feeling that I\x92d be possibly be asked to fly out to Toronto (the JFK guys requested this also) , so I took my passport, a change of clothes etc. with me just in case. Sure enough before I knew it I was on the 10:30 BA001 Concorde to JFK, a Limo taking me immediately across town from JFK to La Guardia. From there I was put on an Air Canada A320 to Toronto, arriving there at about 14:30 local time. (19:30 \x91my\x92 time, I was knackered already). When I got to our Concorde the JFK guys told me that the bits I\x92d sent the previous evening were stuck in Canadian Customs, and it took another hour or so to get our hands on them. We proceeded to get her \x91fixed up\x92 between us, and by about 20:00 local we were serviceable. I phoned the crew at the hotel, telling them of the good news, and was told that as soon as I\x92d checked in and had a shower, we were all going out to dinner (my body clock was now at 02:00). Now the flight crew and cabin crew are well [FONT='Calibri','sans-serif']acclimatised, having been in Canada and the States for FIVE days, but I am now a total wreck, (more so than usual), and w hen I finally got to bed it was around midnight Toronto time (05:00 London time). Now no one (including me) expected to see me for the 07:30 pick up from the hotel in the morning, but somehow I miraculously made it. Because one passenger had gone home to Manchester early, there was a seat available for me on the aircraft (I\x92d expected to have had to fly home subsonic, due to the only other available seat being the flip down flight deck aisle seat; to have sat there for over four hours would have been less than pleasant). So all I now wanted to do was get on the aircraft, collapse into my seat and SLEEP, but I had to wait until all passengers had boarded before I was allocated my seat; 26B right at the back of the aircraft. So here I go, getting onto the aircraft in what I thought was total anonymity when as I get on board the purser in the fwd. galley announces that \x91this is Mr Dude who flew out yesterday from London especially to make sure we don\x92t have to divert again\x92. I just wanted to die as I have to walk the gauntlet of 99 passengers all clapping and cheering all the way to the back of the aircraft, my face as red as a beetroot, and when I finally get to my seat I find that I am sat next to this really lovely elderly lady who wanted a blow by blow account of what had gone on, as well as a running commentary on the flight itself. (Of course alll I wanted to do was sleep, I was totally exhausted, but this old lady was absolutely delightful). About an hour after take-off one of the stewardesses informs me that the crew want me up front urgently, so here I go again walking the length of the cabin up to the flight deck. As I go in the guys said \x91I thought you\x92d fixed the *** ing thing.\x92 \x91I did\x92 replies yours truly, and I took a look at the flight deck panels and everything is normal. The four guys are killing themselves laughing, \x91fooled you\x92 , the flight engineer chirps up with (everything was fine, the joke was on me yet again). I once more stagger back to my seat, and for the rest of the flight I keep my lady passenger friend entertained with Concorde stories all the way back to Manchester. At Manchester there is another few hours wait before we FINALLY fly back down to Heathrow, with yet another load of passengers and I finally go home to bed. In all of my Concorde years I\x92d had many exhausting episodes, but Toronto \x9294 really took the biscuit.

Dude

Last edited by M2dude; 7th Oct 2010 at 22:00 .

7th Oct 2010, 13:57

permalink Post: 523

Well, if the price of a Concorde flight was merely sleep deprivation, then we'd all have been propping our eyelids open with matchsticks!

I presume that the fuel penalty for a locked secondary nozzle was due to the reduced expansion of exhaust gas without the maximum divergent shape?

I presume that the fuel penalty for a locked secondary nozzle was due to the reduced expansion of exhaust gas without the maximum divergent shape?

8th Oct 2010, 09:06

permalink Post: 528

Feathers McGraw

The 10 degree lockout position was a bit of a compromise, to allow the aircraft to operate throughout the normal operating envelope with a secondary nozzle (bucket) at a less than ideal position. See the diagrams below, one showing the bucket control schedule and the other the bucket positions at both take off and supersonic flight: If the buckets are too wide at low Mach numbers then the high velocity exhaust will try and 'drag' the low pressure/low velocity air in the exhaust annulus along with it; this results in a huge reduction in thrust and is termed 'base drag'. That is the whole idea of having the eyelids at the top and bottom of the bucket assembly; to admit free ambient air into this void and mitigate the effects of base drag (and reduce the noise mayhem a little too). If however the buckets are too narrow at high speed/high altitude then we really get a problem; The high pressure/high velocity exhause gas immediately expands against the VERY low presuure ambient air and flares outwards at an accute angle, again losing us serious quantities of thrust The wide open bucket angle gives us this wonderful cushion of secondary intake airflow. (travelling over the top of the rear ramp, through the engine bay and into the nozzle annulus. The eflux can now gently expand against this airflow as it exits the secondary nozzle, taking up the shape of the divergent secion of nozzle.

Now if we are locked at the 10 degree position we are at a position that will give us significant but tolerable losses throughout the flight envelope.

Quote:

| I presume that the fuel penalty for a locked secondary nozzle was due to the reduced expansion of exhaust gas without the maximum divergent shape? |

Now if we are locked at the 10 degree position we are at a position that will give us significant but tolerable losses throughout the flight envelope.

8th Oct 2010, 13:48

permalink Post: 532

Thanks for those nozzle diagrams Dude, they are very useful to visualise what's happening.

I remember reading Stanley Hookers book "Not Much of an Engineer" (I know the feeling ), in which he explains how at Mach 2 the Olympus is only providing about 8% of the total thrust but then goes on to say that at the low speed end of the take-off run it was 100% of the thrust so his designers were not let off the hook. That falls to 82% in subsonic cruise.

), in which he explains how at Mach 2 the Olympus is only providing about 8% of the total thrust but then goes on to say that at the low speed end of the take-off run it was 100% of the thrust so his designers were not let off the hook. That falls to 82% in subsonic cruise.

Ah, found the figures for Mach 2, the inlet provides 63% of the total thrust, exhaust nozzles 29%. That certainly explains why the thinning and re-profiling of the inlet lip was so important to improving the fuel burn, and hence range.

I remember reading Stanley Hookers book "Not Much of an Engineer" (I know the feeling

), in which he explains how at Mach 2 the Olympus is only providing about 8% of the total thrust but then goes on to say that at the low speed end of the take-off run it was 100% of the thrust so his designers were not let off the hook. That falls to 82% in subsonic cruise.

), in which he explains how at Mach 2 the Olympus is only providing about 8% of the total thrust but then goes on to say that at the low speed end of the take-off run it was 100% of the thrust so his designers were not let off the hook. That falls to 82% in subsonic cruise.

Ah, found the figures for Mach 2, the inlet provides 63% of the total thrust, exhaust nozzles 29%. That certainly explains why the thinning and re-profiling of the inlet lip was so important to improving the fuel burn, and hence range.

8th Oct 2010, 14:18

permalink Post: 534

Feathers, these are the joys of afterburning; a totally gas guzzling way of extracting some more thrust from an engine. With Concorde, at 15 degrees TAT, you got a 78% increase in take off fuel flow for, as you say, about a 6000lb increase in thrust. Normaly adding an afterburning/reheat system is a fairly complex and heavy affair; you need both the system itself plus a variable exhaust nozzle. Because Concorde already required the primary nozzle for N1 control, the addition of reheat was at least a relatively simple and lightweight afair. The original Olympus 593-22R engine was really a little lacking in terms of dry thrust, and the addition of the reheat system was deemed essential. Concorde only had a single reheat spray ring and flame-holder, military systems often have several, with a corresponding increase in thrust growth as well as a hyper increase in fuel burn.

Further development plans for the Olypus 593 included a large increase in dry thrust; the reheat being retained only for transonic acceleration. It is such a pity that it was not to be.

Dude

Further development plans for the Olypus 593 included a large increase in dry thrust; the reheat being retained only for transonic acceleration. It is such a pity that it was not to be.

Dude

8th Oct 2010, 14:22

permalink Post: 535

I heard that the combined nozzle and reverser was a unique piece of aviation development.

The story I heard when I was an apprentice at Hurn was that, compared to the prototype multi finger nozzle and separate reverser, the production nozzle was:-

1. More efficient.

2. Lighter.

3. Simpler.

4. Cheaper to make and maintain.

I doubt there have been many developments that meet all 4 items.

Usually the first three can be met, but at great cost.

P.S. I did my bit of Concorde design in the FSDO by re-drawing a cabin bulkhead to reduce weight.

The story I heard when I was an apprentice at Hurn was that, compared to the prototype multi finger nozzle and separate reverser, the production nozzle was:-

1. More efficient.

2. Lighter.

3. Simpler.

4. Cheaper to make and maintain.

I doubt there have been many developments that meet all 4 items.

Usually the first three can be met, but at great cost.

P.S. I did my bit of Concorde design in the FSDO by re-drawing a cabin bulkhead to reduce weight.

9th Oct 2010, 19:10

permalink Post: 539

Dixi188

Actually Rolls Royce always told me that the (new) Type 28 secondary nozzle was a bit of a dissapointment. Aerodynamically it was a far better interface with the wing from a drag point of view than the original design, but fell short of it's design promise in terms of performance. The design responsibility for the secondary nozzle system awarded to the French engine manufacturer SNECMA. They in turn farmed the whole manufacturing side off to STRESSKIN inc., a division of General Motors, and the air motor and electronic control unit were designed and built by Garret Airesearch in the US also.

The original secondary nozzle was 'freely floating, with no actuation; the thrust revereser itself was a pair of cascade doors, driven by an air motor. Tertary air doors opened at low speeds to admit ambient air into the nozzle anulus, instead of the eyelids of the later 'buckets'.

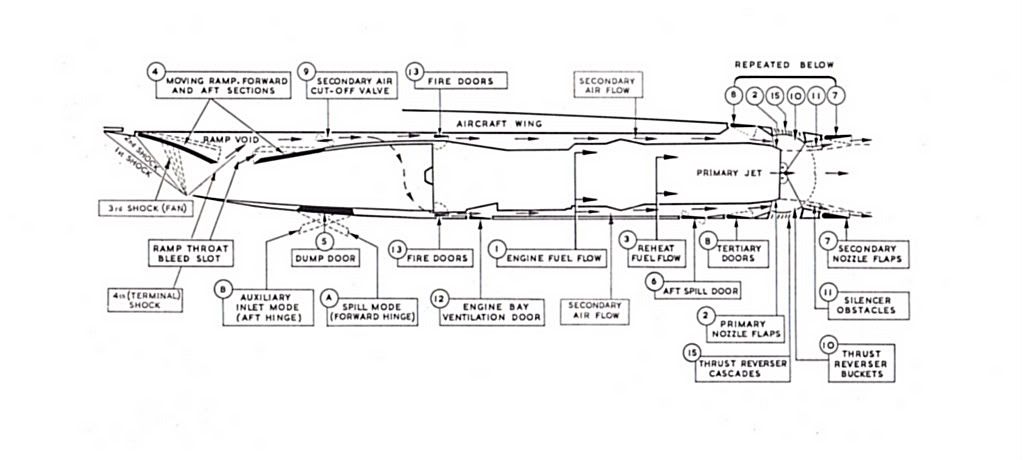

If you look at the diagram below you can see what a complicated animal the prototype powerplant was. The intake dump door (alternative name for spill door) was hinged both at the front AND the rear; either hinge mechanisms automatically releasing at specific Mach numbers. It was the mechanical nightmare that the diagram suggesrs.

Dude

Quote:

|

I heard that the combined nozzle and reverser was a unique piece of aviation development.

The story I heard when I was an apprentice at Hurn was that, compared to the prototype multi finger nozzle and separate reverser, the production nozzle was:- 1. More efficient. 2. Lighter. 3. Simpler. 4. Cheaper to make and maintain. |

The original secondary nozzle was 'freely floating, with no actuation; the thrust revereser itself was a pair of cascade doors, driven by an air motor. Tertary air doors opened at low speeds to admit ambient air into the nozzle anulus, instead of the eyelids of the later 'buckets'.

If you look at the diagram below you can see what a complicated animal the prototype powerplant was. The intake dump door (alternative name for spill door) was hinged both at the front AND the rear; either hinge mechanisms automatically releasing at specific Mach numbers. It was the mechanical nightmare that the diagram suggesrs.

Dude

Last edited by M2dude; 9th Oct 2010 at 21:54 .

9th Oct 2010, 23:51

permalink Post: 541

Looking at the prototype's nozzle arrangements in comparison with that used in the production aircraft, does anyone know how much the secondary nozzle silencing effect actually gained?

I wonder how close to the noise limits the prototypes would have been at JFK....

I wonder how close to the noise limits the prototypes would have been at JFK....

10th Oct 2010, 15:13

permalink Post: 543

Another aspect of Concorde.

All this talk of a 'B' model is both interesting and a bit frustrating. It must be all the more so for our main contributors - M2Dude and ChristiaanJ - and I guess the crews themselves, that the 'B' never saw the light of day. The discussion about the engines/ intakes/ nozzles is taking place about another

flight level

above my head

but still riveting stuff nonetheless.

but still riveting stuff nonetheless.

May I ask a question about another aspect of Concorde life? In my own job as a CT/MRI scanner engineer, I was for many years a 'Registered Radiation Worker' and indeed I still wear the equivalent of a film badge. My annual dose though was and is tiny, virtually background. However, I remember seeing a chart from the Radiological Protection Board some years ago, that seemed to suggest Concorde Crews had the highest radiation dose in any industry routine operations.

Was this true and did Concorde crews wear a film badge as I did? I understand that 'ordinary' flight crews get quite a radiation dose, but nothing like the 60,000ft doses the lady permitted?

Roger.

but still riveting stuff nonetheless.

but still riveting stuff nonetheless.

May I ask a question about another aspect of Concorde life? In my own job as a CT/MRI scanner engineer, I was for many years a 'Registered Radiation Worker' and indeed I still wear the equivalent of a film badge. My annual dose though was and is tiny, virtually background. However, I remember seeing a chart from the Radiological Protection Board some years ago, that seemed to suggest Concorde Crews had the highest radiation dose in any industry routine operations.

Was this true and did Concorde crews wear a film badge as I did? I understand that 'ordinary' flight crews get quite a radiation dose, but nothing like the 60,000ft doses the lady permitted?

Roger.

10th Oct 2010, 23:12

permalink Post: 547

I wonder if my piggy bank will ever stretch to a sim session down at Brooklands? I can but dream.....

Thanks for the engine nozzle comments Dude, it certainly seems that the secondary nozzles got bitten by the law of unintended consequences. All engineers are familiar with that one!

Thanks for the engine nozzle comments Dude, it certainly seems that the secondary nozzles got bitten by the law of unintended consequences. All engineers are familiar with that one!

20th Oct 2010, 10:56

permalink Post: 594

Quote:

| What engine parameters were monitored to provide this indication and how was this done ? |

BLUE reverse light --- this reflected the correct operation of the

reverse thrust.

Flashing, rev selected but buckets in transit

On steady reverse selected and achieved

Amber Configuration

[CON] light----------- ON if reheat fails with no loss of engine RPM

On if reverse selected and primary nozzle greater

than 15%

Green Go light---------- This light monitored the engine for correct power

for take-off in that

Fuel flow and P7 had to match or exceed a pre

calculated figures, which were preset on their

individual gauges prior to take off.

The secondary nozzles had to within their

take-off limits

The CON light is off

In the case of No 4 engine the N1 limiter has

returned to normal position

Now normally there was a call of 100kts and at that point there had to be 4 green GO lights illuminated otherwise the t/off would be aborted. There was a concession to this in that if runway/ conditions /weight allowed the takeoff could continue with only 3 green lights illuminated at 100 kts as long as the

affected basic engine was OK[ this covered the loss of one reheat]

The green lights were considered necessary if the aircraft was using a rough runway and nose nodding could interfer with correct engine instruement monitoring and were also handy as the pilots could at a glance check whether they had at least minimum eng power for t/off.

To keep things simply their use was standard on all T/offs rough or otherwise

22nd Oct 2010, 09:26

permalink Post: 597

OK guys, here are the answers. If you disagree about any of them then fire away, the old memory certainly 'aint perfect.

As many of you have guessed, there were 22: The 14 production airframes, the 2 production series development aircraft (201 & 202), the 2 pre-production airframes (101 & 102) and the 2 prototypes 001 & 002. PLUS, the major fatigue test specimen at the RAE Farnborough and the static test specimen at CEAT in Toulouse. The CEAT tests actually tested the wing to destruction; I seem to remember it was something like a 200% overload before the wing failed at the root. And great but rather sad pictures

VOLUME

, never seen these before.

OK, from MY memory

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

11:15

The BA193 and BA 195.

OK, there were 12 engine feed pumps (3 per engine) 8 main transfer tank pumps (2 each for the transfer tanks 5, 6, 7 & 8), 4 'A' tank pumps (2 each for 5A & 7A), 8 trim-transfer tank pumps (2 electric pumps each for tanks 9, 10 & 11 PLUS 2 hydraulically driven pumps for tank 9), 4 electric engine start pumps (there was a single electric start pump per engine that delivered fuel to it's own dedicated start atomiser in the combustion chamber. The pump automatically ran when the engine HP valve was set to OPEN and would continue running for 30 seconds after the DEBOW switch was returned to the 'normal' position), 4 engine first stage pumps (a single mechanically driven pump per engine), 4 second stage pumps (a single pneumatically driven pump, sometimes termed 'the turbopump, per engine. This would cut out at around 20,000'), our scavenge tank pump (triggered automatically when there was 7 US gallons in the tank; pumping it back into tank 2. This pump was identical to an 'A' tank transfer pump), and FINALLY, a single de-air pump for tank 10. The pump would drive the fuel through a mesh, removing air bubbles from the fuel. Tank 11 used the L/H trim pump for de-air (similar principle)and would be switched on during take-off. This is why the tank 5 trim inlet valve being set to over-ride OPEN would result in the tank being highly pressurised in the case of the Gonesse disaster; the pump would obviously pressurise the L/H trim gallery and any tank on that side with an open inlet valve!!!

G-AXDN, aircraft 101. (A production wing, fuselage, droop nose and intakes, but with the short tail section and secondary nozzles of the prototypes.

Ready ChristiaanJ? There were 18....Yes, the single SFENA standby horizon, 9 INS gyros (one per X,Y and Z platform in each of the 3 INUs), 8 autostab' rate gyros (one per axis for each of the 2 autostab' computers PLUS a monitor gyro for the pitch axis). The radar by the way used attitude signals from the INS.

9. One per main wheel plus the single 'in flight braking' nose wheel brake.

Mach 0.7!!! Between this and Mach 1.26 the intake surfaces were positioned as a function of engine N1 if the engine was shut down for any reason. (Otherwise of course the intake surfaces were fully up). You needed a sub idle N1 of 57% and below for all this to happen, and it was to assist relight performance and reduce buffet. Between Mach 1.26 and 1.32 the ramps were driven down slightly to about 5%, full supersonic scheduling itself commencing at Mach 1.32.

Already brilliantly answered by Brit312 (as well as the FSLabs diagram). Yep, Geen GO, T/O monitor armed, fuel flow and P7 at or above datum, A/C on ground, reverse not selected and CON light not on. Amber CON (Reheat selected and not detected, N1 OK or reverse selected and primary nozzle (Aj) not at minimum. Blue REV; steady buckets at reverse, flashing buckets in transit.

Fairford, followed by Brize Norton, and then a host of airfields from Prestwick and Shannon to Chateauroux.

OK, probably no surprises now:

Landing - 27L & R, 9L & R (prior to LHR mag' deviation update were 28L & R & 10L & R) together with 23/05.

Take off - 27L (28L), 9R (10R) and 9L. (10L never happened as take offs on this runway only occurred in 2003).

It was FedEx, they planned to operate two stripped out aircraft, leased from BA, between Shannon and JFK as high value parcel carriers. The idea was that parcels would be flown in from all over Europe by small FedEx feeder aircraft and the parcels transferred to Concorde which would then speed on to JFK in around 2 1/2 hours. It never happened because of a combination of economics appraisal by FedEx and BA deciding that it could would not release the aircraft anyway.

A/C 101, G-AXDN first flew on 17th December 1971 with FIXED INTAKES!! (101 was going to be the launch vehicle for the new digital intake control system, but the 'boxes' were still being designed). This placed an operating limit of Mach 1.5 on the aircraft, limiting her ability with such a restricted flight envelope. She returned to Filton in late 1972 for installation of the system, as well as the new Olympus 593-602 engine. (The engine, very similar to the production Mk 610 version, used a quite revolutionary annular combustion chamber, and eliminated at a stroke the thick smoke exhaust that had up to then been Concorde's unwanted visual signiture). The aircraft flew more or less smokeless on 15 March 1973, achieving Mach 2 soon afterwards. As ChristiaanJ pointed out, the British prototype 002 had a similar gap, actually significantly higher, of 19 months. (The French aircraft 001 had an even longer gap of some 20 months).

I hope you guys had fun with this one, regards to all

Dude

Quote:

| 1) How many Concorde airframes were built? |

Quote:

| 2) As far as the British constructed aircraft went, name the destinations that were served?. Regular flight numbers only, excludes charters etc. |

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

Quote:

| 3) What was the departure time for the ORIGINAL morning LHR-JFK Concorde services? (Not called the BA001 then either). |

Quote:

| 4) Further to question 3 above, what WERE the original flight numbers for the BA001 and BA003? (The morning and evening LHR-JFK services?). |

Quote:

5) There were no less than FORTY SIX fuel pumps on Concorde. What was the breakdown for these? (Clue; don't forget the scavenge pump

).

).

|

Quote:

| 6) What was the only development airframe to have a TOTALLY unique shape? |

Quote:

| 7) This one is particularly aimed at ChristiaanJ. What was the total number of gyros on the aircraft? |

Quote:

| 8) How many wheel brakes? |

Quote:

| 9) What Mach number was automatic engine variable intake control enabled? |

Quote:

| 10) Above each bank of engine instruments were three lights, a blue, a green and an amber. What did they each signify? |

Quote:

| 11) At what airfield were the first BA crew base training details held? |

Quote:

| 12) What LHR runways did Concorde use for landing and take-off? (Trick question, not as obvious as it might seem). |

Landing - 27L & R, 9L & R (prior to LHR mag' deviation update were 28L & R & 10L & R) together with 23/05.

Take off - 27L (28L), 9R (10R) and 9L. (10L never happened as take offs on this runway only occurred in 2003).

Quote:

| 13) What operator had serious plans to operate Concorde from SNN to JFK in the early 1980's? |

Quote:

| 14) What development aircraft did not exceed Mach 2 until fifteen months after her maiden flight? |

I hope you guys had fun with this one, regards to all

Dude

Last edited by M2dude; 22nd Oct 2010 at 11:21 . Reason: oops, misssed out question 2

24th Oct 2010, 22:18

permalink Post: 602

Consider it done Feathers.

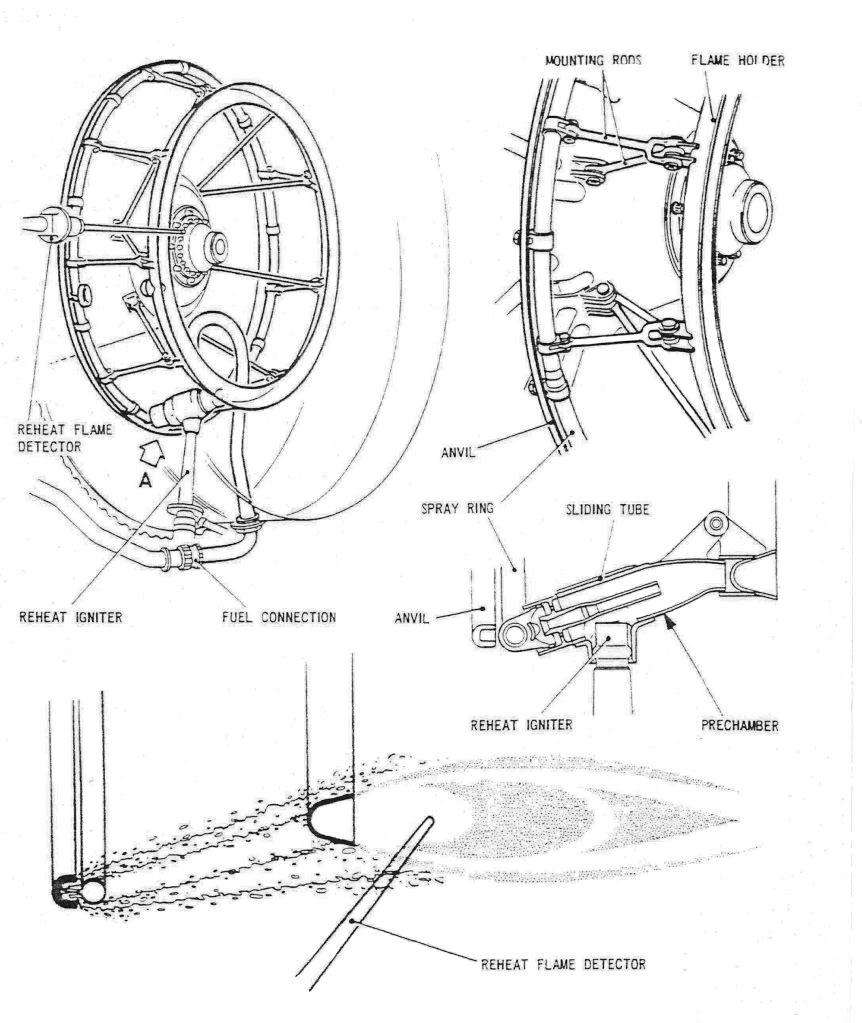

As promised, here are a few diagrams of the Concorde reheat (afterburner, for our American friends) system. The ORIGINAL design was done by SNECMA, but due to them getting into all sorts of trouble with the fuel injection system and flame stabilisation, Rolls Royce baled them out, and it became a Rolls Royce/SNECMA design. (The core engine was a 100% Rolls design, with no French input whatsoever. However some engine sub-assembles were manufactured by SNECMA).

The basic way the afterburner worked was by spraying the fuel FORWARDS intially at high pressure, against the jet stram about one inch, until it hit the anvil. . As the fuel strikes the anvil it is blown back by the jet stram and atomises, passing over the of the spray ring and the over the flame holder. The ignition operated by passing 15KV across a dual cylindrical tube, the resulting arc was 'swirlied' into the fuel stream by blowing engine 5th stage HP compressor air into the tube (there were 7 stages in all).

The key to successful ignition was a healthy spark, a good supply of air to the ignitor and accurate scheduling of fuel flow. (This was scheduled against dry engine flow as a funtion of total temperature). The other important factor (as with any afterburner) was correct and rapid operation of the exhaust nozzle. Fortunately, Concorde used it's primary nozzle for control of engine N1 anyway, so adapting this to operate as an afterburning nozzle also was a relative walk in the park, and it operated superbly.

During the light up phase of 3.5 seconds, the fuel ratio is a fixed 0.45 (ie. reheat fuel is 45% of dry fuel). After the light up phase the full scheduling commenced. As far as the FLIGHT RATING figures go (not take-off) the ratios were 0.6 at a TAT of 54 deg's C, falling linearly to 0.3 at 107 deg's C and above. (Remember that Concorde used afterburning really sparingly, just for take-off and then transonic acceleration; cut off at Mach 1.7 altogether.

Dude

As promised, here are a few diagrams of the Concorde reheat (afterburner, for our American friends) system. The ORIGINAL design was done by SNECMA, but due to them getting into all sorts of trouble with the fuel injection system and flame stabilisation, Rolls Royce baled them out, and it became a Rolls Royce/SNECMA design. (The core engine was a 100% Rolls design, with no French input whatsoever. However some engine sub-assembles were manufactured by SNECMA).

The basic way the afterburner worked was by spraying the fuel FORWARDS intially at high pressure, against the jet stram about one inch, until it hit the anvil. . As the fuel strikes the anvil it is blown back by the jet stram and atomises, passing over the of the spray ring and the over the flame holder. The ignition operated by passing 15KV across a dual cylindrical tube, the resulting arc was 'swirlied' into the fuel stream by blowing engine 5th stage HP compressor air into the tube (there were 7 stages in all).

The key to successful ignition was a healthy spark, a good supply of air to the ignitor and accurate scheduling of fuel flow. (This was scheduled against dry engine flow as a funtion of total temperature). The other important factor (as with any afterburner) was correct and rapid operation of the exhaust nozzle. Fortunately, Concorde used it's primary nozzle for control of engine N1 anyway, so adapting this to operate as an afterburning nozzle also was a relative walk in the park, and it operated superbly.

During the light up phase of 3.5 seconds, the fuel ratio is a fixed 0.45 (ie. reheat fuel is 45% of dry fuel). After the light up phase the full scheduling commenced. As far as the FLIGHT RATING figures go (not take-off) the ratios were 0.6 at a TAT of 54 deg's C, falling linearly to 0.3 at 107 deg's C and above. (Remember that Concorde used afterburning really sparingly, just for take-off and then transonic acceleration; cut off at Mach 1.7 altogether.

Dude