23rd Dec 2010, 17:21

permalink Post: 974

Quote:

|

Originally Posted by

M2dude

HOWEVER, this system was fitted to the #1 system only (1 & 2 were used on alternate flights) and there was no performance penalty when the thing was not working.

|

Dude, Do you know how the #2 system was exhausted if it wasn't through another thrust recovery nozzle? We were never going to throw away 600 lbf thrust every other flight - not on Concorde where we sweated blood to get the parasitic drag down!

Any chance that there was a common discharge point even if the two packs were used alternately?

CliveL

23rd Dec 2010, 18:08

permalink Post: 976

Quote:

|

no.2 system used for inbound flights, and this used the stbd outflow (oops!

discharge

) valves.

No perf penalty, as 'Dude noted. I vaguely recall being told that the drag from the recuperator cancelled a lot of the recovered thrust. I've no idea how true it was......... |

I know it sounds crazy, but that cabin air had to be dumped somewhere, and without those thrust recovery nozzles all the energy it contained would be lost, so that a net zero is actually a win!

CliveL

23rd Dec 2010, 20:01

permalink Post: 980

Quote:

|

Originally Posted by

Brit312

Not sure if I am on the same thread as others but there were definately strengthening straps / doublers fitted on the underside of the wing outboard of the engines, which were on a wing root/wing tip alignment. This surprised everybody as they seemed to go against all the need for limiting drag that had been impressed on us during the lectures.

These strengthening straps were fitted a few years after the start of service due to small cracks appearing in the outer wing, and only seen on BA aircraft. This was put down to the fact that in the early years BA Concordes flew heavy and subsonic for extended periods across Europe, on their route to Bahrain, whereas Air France aircraft always accelerated shortly after take off Also either side of the engines there were two tubes on the underwing which went fore /aft. These tubes were the drain outlet for their respective engine dry bay and directed any fluid to the trailing edge of the wing. |

If there were spanwise straps fitted to BA aircraft after a few years in service that was after my time. They would be a sort of 'crack stopper' and despite the drag would have to go spanwise to carry the loads and would have to be external at that stage in the aircraft life. They would give some additional bending stiffness, but not very much I think. they are probably invisible in any photographs I have - the 'fairings' I have been chuntering on about are the dry bay drains you have just described.

I must admit I am surprised by your remarks on the thrust recovery nozzles though.

CliveL

24th Dec 2010, 11:34

permalink Post: 983

CliveL

The dual pressurisation systems each had two discharge valves, one just aft of the nose undercarriage and the other at the rear of the aircraft. The forward valves would carry away the electronics rack discharge air, where the aft would vent the underfloor area. There was no common discharge point Clive, no. The #2 system forward valve would just throw the air overboard, without the sophisticated 'nozzling' of the #1 system. So I guess we have to go figure just how useful the thrust recuperation system was, but I personally think that EXWOK got it right.

ChristiaanJ

The stiffenersd did not go over the bathtub joints my friend, , they were inboard.

Mike-Bracknell

Unfortunately Mike your photo is a little too far outboard to show them. We need to go a little more inboard and slightly further aft. I've been through my photos and can't yet find one. (Honest CliveJ, it is the truth, they DO exist

).

).

A very happy Christmas to everyone here; Personally I am working right through Christmas AND New Year (darned aeroplanes)

Dude

Quote:

|

Dude, Do you know how the #2 system was exhausted if it wasn't through another thrust recovery nozzle? We were never going to throw away 600 lbf thrust every other flight - not on Concorde where we sweated blood to get the parasitic drag down!

Any chance that there was a common discharge point even if the two packs were used alternately? |

ChristiaanJ

Quote:

|

Any chance of a pic or a drawing, M2dude?

It seems almost impossible to me that it was 'something' between inner and outer wing, since it would have had to 'jump' over the bathtub covers. |

Mike-Bracknell

Quote:

| Since a picture's worth a thousand words, if you guys would like to point to the strengthening straps/spars/thingies on this? |

).

).

A very happy Christmas to everyone here; Personally I am working right through Christmas AND New Year (darned aeroplanes)

Dude

27th Dec 2010, 11:06

permalink Post: 1024

Quote:

|

Originally Posted by

M2Dude

Actually Rolls Royce always told me that the (new) Type 28 secondary nozzle was a bit of a dissapointment. Aerodynamically it was a far better interface with the wing from a drag point of view than the original design, but fell short of it's design promise in terms of performance. The design responsibility for the secondary nozzle system awarded to the French engine manufacturer SNECMA.

|

Seriously, they couldn't possibly know that the new nozzle fell short of it's design promise. There was no means of measuring thrust in flight installed on the aircraft and even if there had been the possible precision would not have allowed one to make such judgement. The only certain thing in aircraft design is weight, and that could be established unequivocably - it was lighter than the original. Any aerodynamicist looking at the two designs could tell you that the drag of the TRA (Tuyere Reverse Aval) was going to be less than that of the prototype nozzle, but establishing an exact value was another matter.

For the record. the idea of a new design originated in Sud Aviation. The development of the design was entrusted to a joint BAC/RR/Sud/Snecma team (I was one of that team, so maybe I am biased!). Snecma were not very keen on the idea of a new nozzle, largely from pride and a strong NIH factor, but one could not in fairness blame them for any performance shortfall - it was a joint effort.

CliveL

27th Dec 2010, 14:04

permalink Post: 1026

A pot pourri of responses after my Christmas reading!

This actually is interesting in that the n umbers show one of the fundamental features that made the Ol 593 such a good choice. If you look closely at the TO and cruise values you will find that at TO the overall compressor pressure ratio is 13.5 the compressor exit temperature 460 degC and the turbine inlet temperaure is 1152 degC. In cruise the pressure ratio is 10.5, the compressor exit is 565 degC and the TET 1100 degC.

Somebody, I can't find the exact post, was asking whether the elevated cruise total temperatures affected engine life, and here we see why this is so. As Christian said in another posting, when you compress air it gets hotter - from 21 degC to 460 degC at take off and from 127 degC to 565 degC in cruise. A fundamental limit on engine operation is the turbine entry temperature. Not only does it affect the maximum TO thrust you can get but also the continued exposure to cruise TETs has a very big effect on engine fatigue life, and engine manufacturers have shown extremes of ingenuity when developing new materials and ways of cooling the blades to increase allowable TET.

The problem with supersonic operations is that you start from an elevated intake delivery temperature so that when the flow exits the compressor it is already very hot 565 instead of 460 to be exact. But the maximum temperature one can stand for fatigue reasons is limited, therefore the amount of fuel you can pour in must be limited also, and the thrust you can develop per pound of airflow is roughly proportional to the fuel input/temperature rise. To get any sensible cruise thrust then one must squeeze the cruise TET as high as you dare for fatigue reasons but also you need to keep the compression ratio down so that the temperature going into the combustion chambers is as low as you can get away with. This tend to drive engines designed for extended supersonic operations to having a low pressure ratio. This is against the trend in subsonic operations where compression ratios have been steadily increasing along with bypass ratios.

The net result then is that the engine must be designed with a low OPR and must operate with cruise TET much closer to its TO TET value than would be necessary, or indeed desirable, on a subsonic design.

Actually, here, as on some other apparent carry-overs, one should look at the equipment supplier rather than the aircraft manufacturer to trace continuity. Here we have Messier supplying Concorde's gear and Dowty (OK they are now part of Messier) supplying the A330. And having worked on both, I seem to remember that the means of doing the shortening are quite different.

Yes, they both came out of the Bristol drawing office. One minor anecdote: the 'ramshorn' stick was a novelty to the Concorde flight test crews but they got to like it, or at least put up with it. All went well until it came to the time when Dave Davies, the ARB Chief Test Pilot, came to put his rubber stamp on the aircraft.

Concorde's seats, just like those on your car, could be moved back and fore to get your legs on the pedals and up and down so you could see over the bonnet (sorry, instrument panel). The control column of course stayed in one place, so the relationship of the 'horns' to ones thighs varied with ones height. Andre Turcat was about 6ft 2in, Trubbie and the others of average height. The smallest regular pilot was Jean Franchi at, I suppose, about 5ft 7 or 5ft 8. No problems. But Dave Davies was short like me and he found that he could not get full back stick and full aileron because the ramshorn fouled his thighs.

Consternation! Completely unacceptable! I don't know what arguments they used to convince him it was all OK really, but it got through certification. I would certainly be interested to learn from the pilots in this group as to whether it was ever a problem.

I can't resist this one!. Has anyone ever noticed/wondered about the tiny bit of the outer elevon that has been chopped off? That was my first real input into the design as a young erk looking at variability of touchdown conditions and coming to the conclusion that if the pilot got into trouble and was trying to pick up a trailing wing with too much AoA as well then he was likely to hit the ground with the downgoing elevon. I persuaded my boss that this was so and we made a small adjustment.

In self defence I am going to plead that this was well before the days of the Type 28 nozzle, so the issue of buckets contacting the ground first never came up!

To the point where an American Airline maintainance engineer, watching a prototype taking off and with full benefit of being located strategically for maximum sideline noise, remarked on what he described as 'visible acoustic radiation'

On another occasion, it was reputed that Stanley Hooker, watching a TO in the company of HRH the Duke of Edinburgh, remarked that "You know Sir that that noise represents less energy than it takes to boil an egg". to which he got the reply "Then I must congratulate you Sir Stanley, on producing so much noise for the expenditure of so little energy".

There was an effect and in consequence the aircraft performance brochures were formally calculated for north/south flight. Pity really, it would sometimes have been nice to be able to fly guarantee performance demonstrations in the most favourable direction

That's enough for today!

CliveL

Quote:

|

Originally Posted by

M2Dude

I hope this one is interesting; it's a Rolls Royce diagram illustrating what the wildly varying differences were in terms of the engine between take off and supersonic cruise. The primary nozzle can be seen at the rear of the engine, together with the reheat assembly and the secondary nozzle (reverser buckets).

|

This actually is interesting in that the n umbers show one of the fundamental features that made the Ol 593 such a good choice. If you look closely at the TO and cruise values you will find that at TO the overall compressor pressure ratio is 13.5 the compressor exit temperature 460 degC and the turbine inlet temperaure is 1152 degC. In cruise the pressure ratio is 10.5, the compressor exit is 565 degC and the TET 1100 degC.

Somebody, I can't find the exact post, was asking whether the elevated cruise total temperatures affected engine life, and here we see why this is so. As Christian said in another posting, when you compress air it gets hotter - from 21 degC to 460 degC at take off and from 127 degC to 565 degC in cruise. A fundamental limit on engine operation is the turbine entry temperature. Not only does it affect the maximum TO thrust you can get but also the continued exposure to cruise TETs has a very big effect on engine fatigue life, and engine manufacturers have shown extremes of ingenuity when developing new materials and ways of cooling the blades to increase allowable TET.

The problem with supersonic operations is that you start from an elevated intake delivery temperature so that when the flow exits the compressor it is already very hot 565 instead of 460 to be exact. But the maximum temperature one can stand for fatigue reasons is limited, therefore the amount of fuel you can pour in must be limited also, and the thrust you can develop per pound of airflow is roughly proportional to the fuel input/temperature rise. To get any sensible cruise thrust then one must squeeze the cruise TET as high as you dare for fatigue reasons but also you need to keep the compression ratio down so that the temperature going into the combustion chambers is as low as you can get away with. This tend to drive engines designed for extended supersonic operations to having a low pressure ratio. This is against the trend in subsonic operations where compression ratios have been steadily increasing along with bypass ratios.

The net result then is that the engine must be designed with a low OPR and must operate with cruise TET much closer to its TO TET value than would be necessary, or indeed desirable, on a subsonic design.

Quote:

|

I

s this another item that Airbus used for the A330/340? I can't remember the exact arrangement for Concorde, but the 330 uses a clever lever arrangement at the top of the leg.

I was not even aware of this A33/340 similarity, sounds yet another case of Airbus using Concorde technology. (Immitation still is the greatest form of flattery I guess). As far as I am aware Concorde had none of the lubrication issues that you describe. M2Dude |

Actually, here, as on some other apparent carry-overs, one should look at the equipment supplier rather than the aircraft manufacturer to trace continuity. Here we have Messier supplying Concorde's gear and Dowty (OK they are now part of Messier) supplying the A330. And having worked on both, I seem to remember that the means of doing the shortening are quite different.

Quote:

|

Originally Posted by

Brit312

The Britannia and now you are talking about the love of my life and yes I do remember the story of the nose and visor selector, but we have forgotten the most obvious. Where do you think they got the idea for the control column from

|

Yes, they both came out of the Bristol drawing office. One minor anecdote: the 'ramshorn' stick was a novelty to the Concorde flight test crews but they got to like it, or at least put up with it. All went well until it came to the time when Dave Davies, the ARB Chief Test Pilot, came to put his rubber stamp on the aircraft.

Concorde's seats, just like those on your car, could be moved back and fore to get your legs on the pedals and up and down so you could see over the bonnet (sorry, instrument panel). The control column of course stayed in one place, so the relationship of the 'horns' to ones thighs varied with ones height. Andre Turcat was about 6ft 2in, Trubbie and the others of average height. The smallest regular pilot was Jean Franchi at, I suppose, about 5ft 7 or 5ft 8. No problems. But Dave Davies was short like me and he found that he could not get full back stick and full aileron because the ramshorn fouled his thighs.

Consternation! Completely unacceptable! I don't know what arguments they used to convince him it was all OK really, but it got through certification. I would certainly be interested to learn from the pilots in this group as to whether it was ever a problem.

Quote:

|

Originally Posted by

exWok

........which was one reason it was so important to touch down with the wings level - even a very small angle of bank could result in bucket contact as they translated to the reverse position. It was a surprise coming to Concorde to find it was even more restrictive than the 747 in this respect

|

I can't resist this one!. Has anyone ever noticed/wondered about the tiny bit of the outer elevon that has been chopped off? That was my first real input into the design as a young erk looking at variability of touchdown conditions and coming to the conclusion that if the pilot got into trouble and was trying to pick up a trailing wing with too much AoA as well then he was likely to hit the ground with the downgoing elevon. I persuaded my boss that this was so and we made a small adjustment.

In self defence I am going to plead that this was well before the days of the Type 28 nozzle, so the issue of buckets contacting the ground first never came up!

Quote:

| As far as your point about the prototype engines; they were way down on thrust anyway, (even without the 'help' of the silencers), produced more black smoke than a 1930's coal fired power station. |

To the point where an American Airline maintainance engineer, watching a prototype taking off and with full benefit of being located strategically for maximum sideline noise, remarked on what he described as 'visible acoustic radiation'

On another occasion, it was reputed that Stanley Hooker, watching a TO in the company of HRH the Duke of Edinburgh, remarked that "You know Sir that that noise represents less energy than it takes to boil an egg". to which he got the reply "Then I must congratulate you Sir Stanley, on producing so much noise for the expenditure of so little energy".

Quote:

|

Originally Posted by

CJ

One example : in theory the aircraft did weigh 1.2 % less, so the lift was 1.2 % less and the drag was 1.2 % less, so the fuel consumption was less too, so did Concorde have another 50-odd miles range thrown in 'free' by flying higher and faster than it's low-down subsonic brethren?

|

There was an effect and in consequence the aircraft performance brochures were formally calculated for north/south flight. Pity really, it would sometimes have been nice to be able to fly guarantee performance demonstrations in the most favourable direction

That's enough for today!

CliveL

3rd Jan 2011, 07:40

permalink Post: 1072

ChristiaanJ

Although it looks messy and there are parts missing (LE, nozzles and probably tail cone) none of them would take long to fit, which is why I estimated a couple of weeks before rollout, but I wouldn't quarrel with a longer time.

I knew the company merger was in 1970, but AS took a while to decide that they wanted to be known as Aerospatiale, so I thought that maybe, just maybe, this fell into that time slot. Obviously it didn't.

AZR

Your eyesight is better than mine! I had to fiddle with PSP to see it, but yes, the Aerospatiale logo is there. I was fooled by seeing the red fuselage stripe underneath into thinking that cover was more transparent than it actually was.

CliveL

Although it looks messy and there are parts missing (LE, nozzles and probably tail cone) none of them would take long to fit, which is why I estimated a couple of weeks before rollout, but I wouldn't quarrel with a longer time.

I knew the company merger was in 1970, but AS took a while to decide that they wanted to be known as Aerospatiale, so I thought that maybe, just maybe, this fell into that time slot. Obviously it didn't.

AZR

Your eyesight is better than mine! I had to fiddle with PSP to see it, but yes, the Aerospatiale logo is there. I was fooled by seeing the red fuselage stripe underneath into thinking that cover was more transparent than it actually was.

CliveL

4th Jan 2011, 11:58

permalink Post: 1075

First of all a hearty 'Happy New Year' to all our readers. As I've been 'away' for a week or so, I hope you will all indulge me as I answer a few posted points. (I totally agree with what Bellerophon said about restricting our posts to the 'techy' and nostalgic stuff, so will not respond to anything else here)

.

.

CliveL

I accept and understand of course Clive that this was a difficult issue to predict with any certainty, it was just a shame that's all, that the Type 28 never fully lived up to its promise and potential. However, the one aspect of the SNECMA design that was very poor indeed was Secondary Nozzle system integrity. Throughout the operational life of Concorde, there were almost more operational disruptions due to short-fallings here (bucket runaways) than any other issue. It was only near the very end of Concorde's operational life that modifications were finally forthcoming from SNECMA to address this.

Poornamechoice

I am so sorry to dispel this particularly charming story, but there were absolutely no keys as such for Concorde, Sorry

(But I am so glad that you are enjoying this wonderful thread).

(But I am so glad that you are enjoying this wonderful thread).

ChristiaanJ

Oooooh speaking for myself (and I suspect a whole lot more of the BA Concorde familly) there is a void alright. Having lived with the 'lady' day in, day out for almost 30 years (up to November 2003) there was an absolutely yawning chasm left for me personally. (The world of the blunties is just not the same.. just a whole lot slower

).

).

What is gratifying though, is the enormous amount of interest that there still is for Concorde; both in this thread and in the world at large. I guess she lives on after all.

These pictures of 101 etc are absolutely marvellous; I really like the 'sexy' wing shape photo's. One little unique point about 102; she flew with a different intake control system to any other Concorde, being an 'improved' Ultra Electronics analog system. (Although the intake itself was aerodynamically the same as the later aircraft). Never really understood why our French friends chose this particular path with this aircraft. (Perhaps CliveL can shed some light on this??).

Very best regards to all.

Dude

.

.

CliveL

Quote:

| Seriously, they couldn't possibly know that the new nozzle fell short of it's design promise. There was no means of measuring thrust in flight installed on the aircraft and even if there had been the possible precision would not have allowed one to make such judgement. The only certain thing in aircraft design is weight, and that could be established unequivocably - it was lighter than the original. Any aerodynamicist looking at the two designs could tell you that the drag of the TRA (Tuyere Reverse Aval) was going to be less than that of the prototype nozzle, but establishing an exact value was another matter. |

Poornamechoice

Quote:

| My grandad (departed earth long before I was old enough to ask him questions about it unfortunately) worked for a company (don't believe they were a specific aerospace firm just a precision engineering firm, he also worked on flaps/droops on Tridents and said he had many a sleepless night when G-ARPI initially crashed). They won the contract to make the keys for Concorde, my grandad makes the keys according to the designs, and for extra measure thinking they will be a souvenir no doubt one day decides he will make a set for himself (and who knows, I could've ended up with them). So the story goes the dies then get destroyed. Launch day of Concorde comes, BA lose the set of original keys made and only asked ever for one set - the launch looks in jeopardy and a somewhat panicked launch party are wondering what they are going to do. Luckily my grandad steps up and says you have been saved, as he had a spare set all along and gives them to BA who launch as planned but loses out his souvenir in the long run. |

(But I am so glad that you are enjoying this wonderful thread).

(But I am so glad that you are enjoying this wonderful thread).

ChristiaanJ

Quote:

|

It is clear from this fabulous thread that the passing of Concorde has left an aching void in the lives of the contributors here. Maybe, and maybe not.

Speaking for myself, no, it's not a void, it's a highlight, that I now like passing on, in the hope other generations will find inspiration in the 'Concorde Story' for their own endeavours. |

).

).

What is gratifying though, is the enormous amount of interest that there still is for Concorde; both in this thread and in the world at large. I guess she lives on after all.

These pictures of 101 etc are absolutely marvellous; I really like the 'sexy' wing shape photo's. One little unique point about 102; she flew with a different intake control system to any other Concorde, being an 'improved' Ultra Electronics analog system. (Although the intake itself was aerodynamically the same as the later aircraft). Never really understood why our French friends chose this particular path with this aircraft. (Perhaps CliveL can shed some light on this??).

Very best regards to all.

Dude

Last edited by M2dude; 5th Jan 2011 at 16:54 . Reason: Still can't spell

13th Jan 2011, 11:10

permalink Post: 1083

Quote:

|

Originally Posted by

M2Dude

Really an answer for CliveL, but I'll have a go. The short answer to your question is 'oh yeah, big time'. Total temperature varies with the SQUARE of Mach number and static temperature. Depending on the height of the tropopause itself as well as other local factors, there can be little or no significant variation of static temperature between FL600 and FL700. The 400\xb0K (127\xb0C) Tmo limit was imposed for reasons of thermal fatigue life, and equates to Mach 2.0 at ISA +5. (Most of the time the lower than ISA +5 static air temperatures kept us well away from Tmo). In a nutshell, flying higher in the stratosphere gains you very little as far as temperature goes. (Even taking into account the very small positive lapse above FL 650 in a standard atmosphere). As far as the MAX SPEED bit goes, Concorde was as we know flown to a maximum of Mach 2.23 on A/C 101, but with the production intake and 'final' AICU N1 limiter law, the maximum achievable Mach number in level flight is about Mach 2.13. (Also theoretically, somewhere between Mach 2.2 and 2.3, the front few intake shocks would be 'pushed' back beyond the lower lip, the resulting flow distortion causing multiple severe and surges).

On C of A renewal test flights (what I always called the 'fun flights') we DID used to do a 'flat' acceleration to Mach 2.1 quite regularly, as part of the test regime, and the aircraft used to take things in her stride beautifully. (And the intakes themselves were totally un-phased by the zero G pushover that we did at FL630) |

As usual Dude you beat me to it! I really must give up having another life

As Dude says, the 'cruise' condition was set by the aircraft specification for transatlantic range on an 85% (ISA +5) day and the chosen mach Number was 2.0 (of which more anon). This gives a Total Temperature of 400.1 deg K. [Dude, I know your pipe-smoking thermodynamicist and he was having you on - he is quite capable of memorising the square/square root of 407.6 or whatever!]

To give margins for sudden changes in ambient temperature (we had to cater for a 21 deg change in one mile) the Mmo was set at 2.04 which matches 400 degK at ISA +1. In theory then we could have flown faster than our chose Mmo at anything colder than this, but there are two limits:

1) The object is not to fly as fast as you can but to fly with minimum miles/gallon. If you have a nice cold day and enough thrust to go either faster or higher which do you choose? For best specific range you go higher every time.

2) The thing that everyone forgets is that civil aircraft have to have margins around their authorised envelope. In Concorde's case these were set principally by the intake limits and engine surge.

Dude also says quite correctly that 101 flew to 2.23M but the production aircraft was limited to 2.13M. Now you may not believe this, but 101 could fly faster than the production aircraft because she (101) leaked like a sieve!.

I doubt I will get away with that without some explanation

Once you get past a certain Mach Number the airflow into the intake is fixed. The performance (intake pressure recovery and engine face flow distortion) then depends on how this air is shared between the engine and the throat 'bleed'. This bleed was ducted over the engine as cooling air and then exhausted (in principle) throught the annulus formed between the expanding primary jet and the fixed walls of the con-di nozzle. But if you took, or tried to take, more bleed air the intake pressure recovery went up and the primary jet pipe pressure went up with it. This meant that the primary jet expanded more and squeezed the available annulus area which restricted the amount of bleed air one could take.

Obviously if there are alternative exit paths between intake and final nozzle then you can take more bleed air off and the engine face flow distortions will benefit along with the surge margin. 101 was fairly 'leaky' in this respect, particularly around the thrust reverser buckets on the original nozzle design. This meant that 101's intake distortions were lower than the production aircraft so she could fly faster without surge - at least with the first attempt at intake control 'laws'. We managed to tweak most of the margin back eventually. Engine bay leaks were good for surge margin but VERY bad news for m.p.g.!

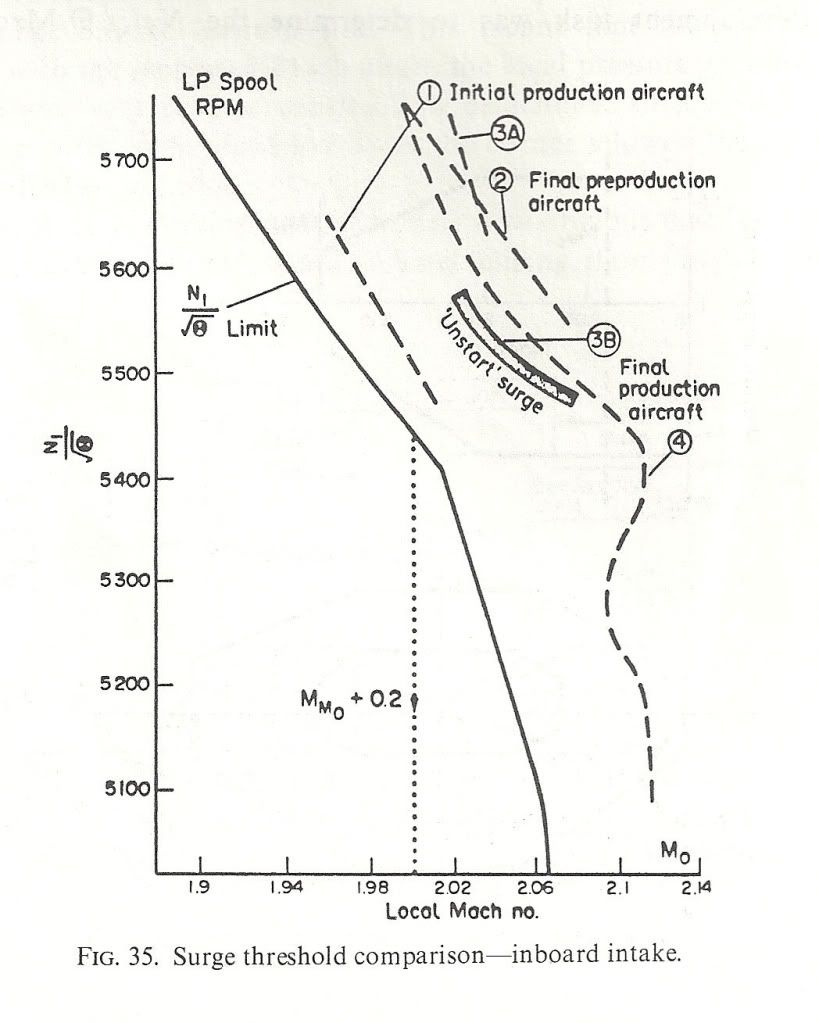

Here are a couple of diagrams to show what I mean. the first shows the surge lines for the various aircraft variants and also the N1 limiter Dude was talking about. NB: the X-axis is LOCAL Mach Number not freestream. The difference comes from the compression of the underwing flow by the bit of the wing ahead of the intake. Mmo + 0.2 is shown

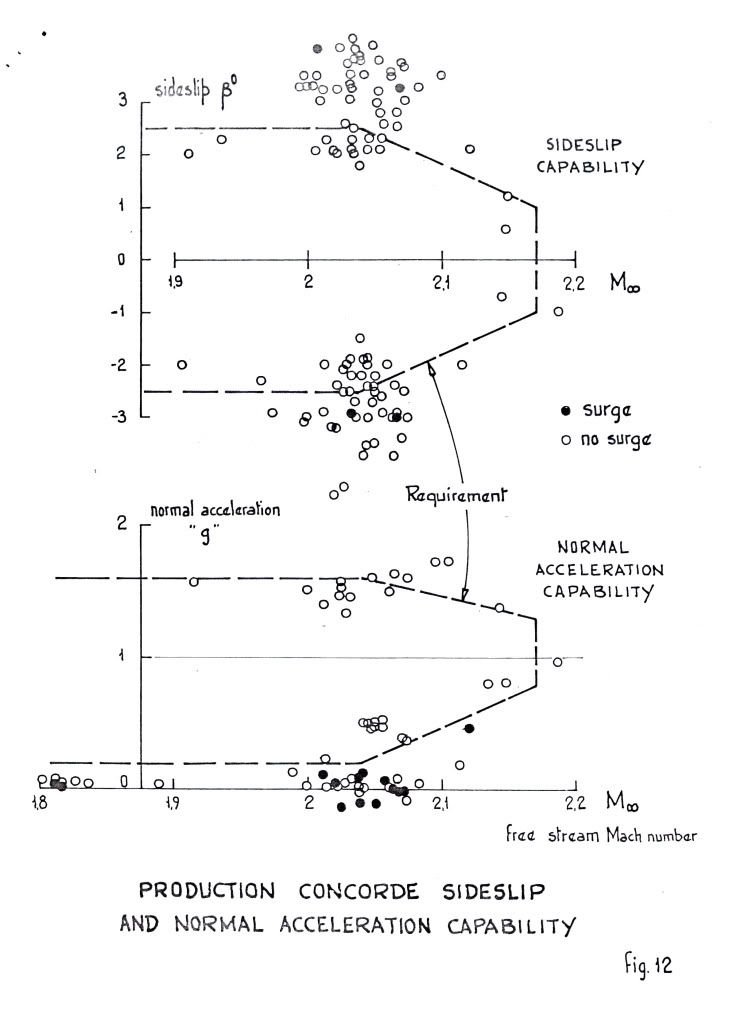

">The next shows the surge free boundaries in sideslip and normal acceleration. You can see the zero 'g' capability Dude was enthusing over.

">The next shows the surge free boundaries in sideslip and normal acceleration. You can see the zero 'g' capability Dude was enthusing over.

">

">

As for 'high speed stall', I don't think we ever contemplated trying it! Our requirements in 'g' capability were defined and that was it. Besides, the aircraft would fly like the proverbial stone-built outbuilding at those sorts of conditions so I don't think one would have been able to get anywhere near a stall in the conventional sense. Stall as commonly defined for subsonics (deterrent buffet) might have been another matter, but I don't remember anything.

Cheers

Last edited by CliveL; 13th Jan 2011 at 11:17 . Reason: additional explanation

18th Jan 2011, 09:30

permalink Post: 1122

I so remember the BAe AST images from the 1980s, I always thought what a potentially nice looking aeroplane she was. I guess that vastly improving the L/D & T/W ratios could go quite a long way to improving the operating economics, but the noise issue was always going to be the crippler. (I know that they were looking at a 'leaky' version of the OLY593, ie. a very low bypass ratio, but this of course would still not really cut the mustard as far as noise goes). I guess there are no current takers then

Clive, you really surprise me when you say you don't think that composites would be used from a future SST, is there a material reason for this? (I'm curious because being of a simple avionic brain, I always assumed composites would be used. But if anyone knows this stuff, you certainly would Clive ).

).

To answer Mike-Bracknell's original query, as far as avionics goes we can really go to town. For her age Concorde had some truly amazing aircraft systems, for instance the flying controls. To enable mechanical control (both FBW channels failed) there was a highly complex and heavy mixing unit under the rear floor. (To mix pitch and roll pilot mechanical demands into differential elevon demand inputs). This of couse would have to be done away with, as well as the relay jacks and replaced with a pair of side-sticks. (See posts on previous page). A 2 crew operation would obviously be the way to go, but neither desirable or possible in my view when Concorde was designed. A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

Best regards

Dude

Clive, you really surprise me when you say you don't think that composites would be used from a future SST, is there a material reason for this? (I'm curious because being of a simple avionic brain, I always assumed composites would be used. But if anyone knows this stuff, you certainly would Clive

).

).

To answer Mike-Bracknell's original query, as far as avionics goes we can really go to town. For her age Concorde had some truly amazing aircraft systems, for instance the flying controls. To enable mechanical control (both FBW channels failed) there was a highly complex and heavy mixing unit under the rear floor. (To mix pitch and roll pilot mechanical demands into differential elevon demand inputs). This of couse would have to be done away with, as well as the relay jacks and replaced with a pair of side-sticks. (See posts on previous page). A 2 crew operation would obviously be the way to go, but neither desirable or possible in my view when Concorde was designed.

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

Best regards

Dude

6th Mar 2011, 22:12

permalink Post: 1234

No thrust vectoring. The secondary nozzles did go to 'divergent' setting from 'convergent' for supercruise, but the thrust was always in the same direction (rearwards).

If the thrust had been angled downwards, it would simply have induced a nose-down pitching moment. Most undesireable!

If the thrust had been angled downwards, it would simply have induced a nose-down pitching moment. Most undesireable!

8th Apr 2011, 01:00

permalink Post: 1277

Unique design.

Quote:

| I can think of no other design in the world, before or since, civil or military, where a supersonic engine/intake marriage gave such incredidable levels of performance, stability and predictability. |

Quote:

|

Without proper scheduling, disturbances inside the inlet could result

in the shock wave being expelled forward--a phenomenon known as an "inlet unstart." That causes an instantaneous loss of engine thrust, explosive banging noises and violent yawing of the aircraft--like being in a train wreck. Unstarts were not uncommon at that time in the SR-71's development, |

Basically, a relatively small failure within the intake/spike structure of the SR71 engine, was enough to simply tear the airframe apart within seconds of onset. The scale of forces within these structures therefore, must be almost beyond imagination and yet the Concorde design was such that she did not suffer such destructive failures.

My admiration for everyone who worked on her is endless.

3rd Jun 2011, 11:35

permalink Post: 1379

Ground Running Concorde

I've been away 'cruising' for a few weeks (lecturing about Concorde) and thought it was time I popped back into this wonderful forum.

There were a few questions regarding ground running Concorde, so here are some 'facts' as far as I recall (Wrinkled old brain permitting).

Concorde was ALWAYS ground run in the detuners at the BA Engineering base at Heathrow, with the parking brake ON. (Save idle runs on the ramp after, say, replacing a PNC actuator etc. on departure. The required high power nozzle trim run could be deferred until the aircrafts return to LHR). Sadly I can confirm that the Concorde 'Hush House' was being demolished when I was last over the engineering patch a few weeks ago, and is probably all gone now.

The detuner chocks were like nothing else you could imagine. They were HUGE steel affairs that needed wheels to be wound down in order to move into position (took a couple of guys at least to move). Once in position forward and aft of the undercarriage, the wheels would be retracted and these 'chocks' would be tension chained together. Believe me, nothing was going to move these suckers!!

Engines WERE NOT run in symmetrical pairs, but the adjacent engine always was run at idle power. The reason for this was so that there was airflow over the T1 probe of the adjacent engine, a winding in this being used by the alternate engine control lane if needs meant it might be required if the main lane failed during the engine run. The way that the aircraft was tethered meant that symmetrical high power running was not any sort of issue.

We were very mean too. In the summer the hangar doors of TBK opposite would invariably be open during the day, the challenge was to see how long it took for us to make them close the doors to shut out the din. (Like I said, Concorde engineers were mean ).

).

Good to be back

Best regards to all

Dude

There were a few questions regarding ground running Concorde, so here are some 'facts' as far as I recall (Wrinkled old brain permitting).

Concorde was ALWAYS ground run in the detuners at the BA Engineering base at Heathrow, with the parking brake ON. (Save idle runs on the ramp after, say, replacing a PNC actuator etc. on departure. The required high power nozzle trim run could be deferred until the aircrafts return to LHR). Sadly I can confirm that the Concorde 'Hush House' was being demolished when I was last over the engineering patch a few weeks ago, and is probably all gone now.

The detuner chocks were like nothing else you could imagine. They were HUGE steel affairs that needed wheels to be wound down in order to move into position (took a couple of guys at least to move). Once in position forward and aft of the undercarriage, the wheels would be retracted and these 'chocks' would be tension chained together. Believe me, nothing was going to move these suckers!!

Engines WERE NOT run in symmetrical pairs, but the adjacent engine always was run at idle power. The reason for this was so that there was airflow over the T1 probe of the adjacent engine, a winding in this being used by the alternate engine control lane if needs meant it might be required if the main lane failed during the engine run. The way that the aircraft was tethered meant that symmetrical high power running was not any sort of issue.

We were very mean too. In the summer the hangar doors of TBK opposite would invariably be open during the day, the challenge was to see how long it took for us to make them close the doors to shut out the din. (Like I said, Concorde engineers were mean

).

).

Good to be back

Best regards to all

Dude

Last edited by M2dude; 4th Jun 2011 at 20:03 .

25th Jun 2012, 15:13

permalink Post: 1643

NHerby

WOW! Talk about asking the 64000$ question up front!

It would take a book to answer your questions properly. Luckily someone has already written it - try to get hold of Ken Owen's "Concorde New Shape in the Sky" ISBN 0 7106 0268 5. It is an excellent account of the genesis and development of the machine that drove my life for 25 years.

You are right - it was a political agreement, but politics after all the art of agreeing what is possible, and we are talking of the UK and France of the 1950s. No way that either of those two proud countries was going to let the other have the lion's share of the kudos and fun of developing and flying the world's first supersonic airliner. Fun? yes, exciting, challenging, exhausting but definitely fun. and no way it was going to be other than an equal split.

and no way it was going to be other than an equal split.

But one can easily argue that it was arranged so that each country contributed the best it had to offer. The actual split was 50/50 on total costs, but arranged so that the UK had 60% of powerplant and 40% airframe. At the time, France had nothing to compare with the Olympus as an engine suitable for supersonic cruise, so that was logical. Out of our 40% on airframe we had responsibility for the intake and for powerplant/airframe integration. But when it came down to brass tacks Onera had a more flexible intake design than anything we Brits had to offer, and later in the project the "TRA" nozzle also came from France. We can take a lot of credit for melding these into a very successful powerplant, but I think it fair to say that each country did, in fact, contribute the best it had to offer.

As for fair shares for all, well all I can say is that there was more than enough work to go around

Quote:

| The 1962 treaty talks about an equal share of work and expenditure between Fr and UK... That sounds very political and not very realistic! A more pragmatic way would have been to take the best each country had to offer. But, in the end, was the share really fair for everybody? |

It would take a book to answer your questions properly. Luckily someone has already written it - try to get hold of Ken Owen's "Concorde New Shape in the Sky" ISBN 0 7106 0268 5. It is an excellent account of the genesis and development of the machine that drove my life for 25 years.

You are right - it was a political agreement, but politics after all the art of agreeing what is possible, and we are talking of the UK and France of the 1950s. No way that either of those two proud countries was going to let the other have the lion's share of the kudos and fun of developing and flying the world's first supersonic airliner. Fun? yes, exciting, challenging, exhausting but definitely fun.

and no way it was going to be other than an equal split.

and no way it was going to be other than an equal split.

But one can easily argue that it was arranged so that each country contributed the best it had to offer. The actual split was 50/50 on total costs, but arranged so that the UK had 60% of powerplant and 40% airframe. At the time, France had nothing to compare with the Olympus as an engine suitable for supersonic cruise, so that was logical. Out of our 40% on airframe we had responsibility for the intake and for powerplant/airframe integration. But when it came down to brass tacks Onera had a more flexible intake design than anything we Brits had to offer, and later in the project the "TRA" nozzle also came from France. We can take a lot of credit for melding these into a very successful powerplant, but I think it fair to say that each country did, in fact, contribute the best it had to offer.

As for fair shares for all, well all I can say is that there was more than enough work to go around

8th May 2013, 16:05

permalink Post: 1714

For the french speaking (or reading) people here, I just found a mine of very interesting informations about Concorde on this website:

Accueil

This site has a database of thousand of concorde flights with the following datas: Date and time of the flight, airframe used, technical and commercial crews, guests, departure/arrival airports and flight type (regular, charter world tour...).

On top of that, many infos and stories around Concorde can also be found there.

I can't resist to translate one of those stories (I'm far from being a native english speaker or a professional translator; so forgive me for the misspellings and other translation mistakes). It is a report about one of the biggest incident that happened to the prototype 001 during the flight tests:

Shock of shockwaves

We were flying with Concorde at Mach 2 since 3 month already on both side of the Channel. The prototype 001 did outstrip 002 which was supposed to be the first to reach Mach 2.

Unfortunately, a technical issue delayed 002 and Brian Trubshaw fairly let Andr\xe9 Turcat be the first to reach Mach 2 with the 001 which was ready to go.

The flight tests were progressing fast and we were discovering a part of the atmosphere that military aircrafts hardly reached before. With Concorde, we were able to stay there for hours although limited by the huge fuel consumption of the prototypes.

The Olympus engines did not reached their nominal performance yet and, most of the time, we had to turn on the reheat in supersonic cruise to maintain Mach 2.

The reheat is what we call afterburner on military aircrafts. Fuel is injected between the last compressor stage of the low pressure turbine and the first exhaust nozzle. This increases the thrust for the whole engine and its nozzle.

The 4 reheats, one for each engine, are controlled by the piano switches behind the thrust leavers on the center pedestal between the two pilots. Air was fed into the engines through 4 air intakes, one for each engine, attached 2 by 2 to the 2 engine nacelle, one under each wing. The advantage in terms of drag reduction was obvious.

However, tests in wind tunnel showed that, at supersonic speed, if a problem happens on one engine, there was a great chance for the adjacent engine to be affected as well by the shockwave interference from one air intake to the other despite the presence the dividing wall between the two intakes. So we knew that an engine failure at mach 2 would result in the loss of 2 engines on the same side, resulting in a lateral movement leading to a strong sideslip that would likely impact the 2 remaining engines and transform the aircraft into the fastest glider in the world.

This is why an automatic anti sideslip device was developed and installed on the aircrafts.

The air intakes are very sophisticated. At mach 2, it creates a system of shockwaves that slows down the air from 600 m/sec in front of the aircraft to 200 m/sec in front of the engine while maintaining a very good thermodynamic performance. In supersonic cruise, the engines, operating at full capacity all the time, were sensitive to any perturbation and reacted violently with engine surge: the engine refusing the incoming air.

Stopping suddenly a flow of almost 200kg of air per second traveling at 600m/sec causes a few problems. As a result, a spill door was installed under the air intake and automatically opened in such event.

To control the system of shockwaves and obtain an efficiency of 0,96 in compression in the air intake, 2 articulated ramps, controlled by hydraulic jacks, are installed on the top of the air intakes in front of the engines. Each ramp is roughly the size of a big dining room table, and the 2 ramps, mechanically synchronized, move up or down following the instruction of an highly sophisticated computer that adapts the ramp position according to the mach number, the engine rating and other parameters such as skidding.

At that time, it was the less known part of the aircraft, almost only designed through calculation since no simulator, no wind tunnel, did allow a full scale test of the system.

The control of the system was analog and very complex but it was not easy to tune and we were moving ahead with a lot of caution in our test at mach 2.

On the 26th of January 1971, we were doing a nearly routine flight to measure the effect of a new engine setting supposed to enhance the engine efficiency at mach 2. It was a small increase of the rotation speed of the low pressure turbine increasing the air flow and, as a result, the thrust.

The flight test crews now regularly alternate their participation and their position in the cockpit for the pilots.

Today, Gilbert Defer is on the left side, myself on the right side, Michel R\xe9tif is the flight engineer, Claude Durand is the main flight engineer and Jean Conche is the engine flight engineer. With them is an official representative of the flight test centre, Hubert Guyonnet, seated in the cockpit's jump seat, he is in charge of radio testing.

We took off from Toulouse, accelerated to supersonic speed over the Atlantic near Arcachon continuing up to the north west of Ireland.

Two reheats, the 1 and the 3, are left on because the air temperature does not allow to maintain mach 2 without them.

Everything goes fine. During the previous flight, the crew experienced some strong turbulence, quite rare in the stratosphere and warned us about this. No problem was found on the aircraft.

We are on our way back to Toulouse off the coast of Ireland. Our program includes subsonic tests and we have to decelerate.

Gilbert is piloting the aircraft. Michel and the engineers notify us that everything is normal and ready for the deceleration and the descent.

We are at FL500 at mach 2 with an IAS of 530 kt, the maximum dynamic pressure in normal use.

On Concorde, the right hand seat is the place offering the less possibility to operate the systems. But here, we get busy by helping the others to follow the program and the checklists and by manipulating the secondary commands such as the landing gear, the droop nose, the radio navigation, comms, and some essential engine settings apart from the thrust leavers such as the reheat switches.

The normal procedure consists in stopping the reheat before lowering the throttle.

Gilbert asks me to do it. After, he will slowly reduce the throttle to avoid temporary heckler. Note that he did advise us during the training on the air intake to avoid to move the thrust leaver in case of engine surge.

As a safety measure, I shut down the reheat one by one, checking that everything goes fine for each one. Thus I switch off the reheat 1 with the light shock marking the thrust reduction. Then the 3\x85

Instantly, we are thrown in a crazy situation.

Deafening noise like a canon firing 300 times a minute next to us. Terrible shake. The cockpit, that looked like a submarine with the metallic and totally opaque visor obviously in the upper position, is shaken at a frequency of 5 oscillation a second and a crazy amplitude of about 4 to 5 G. To the point that we cannot see anymore, our eyes not being able to follow the movements.

Gilbert has a test pilot reaction, we have to get out of the maximum kinetic energy zone as fast as possible and to reduce speed immediately. He then moves the throttle to idle without any useless care.

During that time, I try, we all try to answer the question: what is going on? What is the cause of this and what can we do to stop it?

Suspecting an issue with the engines, I try to read the indicators on the centre control panel through the mist of my disturbed vision and in the middle of a rain of electric indicators falling from the roof. We cannot speak to each other through the intercom.

I vaguely see that the engines 3 and 4 seem to run slower than the 2 others, especially the 4. We have to do something. Gilbert is piloting the plane and is already busy. I have a stupid reaction dictated by the idea that I have to do something to stop that, while I can only reach a few commands that may be linked to the problem.

I first try to increase the thrust on number 4 engine. No effect so I reduce frankly and definitively. I desperately look for something to do from my right hand seat with a terrible feeling of being helpless and useless.

Then everything stops as suddenly as it started. How long did it last, 30 seconds, one minute?

By looking at the flight data records afterward, we saw that it only last\x85 12 seconds!

However, I have the feeling that I had time to think about tons of things, to do a lot of reasoning, assumption and to have searched and searched and searched\x85! It looked like my brain suddenly switched to a fastest mod of thinking. But, above all, it's the feeling of failure, the fact that I was not able to do anything and that I did not understand anything that remains stuck in my mind forever.

To comfort me, I have to say that nobody among the crew did understand anything either and was able to do anything, apart from Gilbert.

The aircraft slows down and the engine 3 that seemed to have shut down restart thanks to the auto ignition system. But the 4 is off indeed.

Michel makes a check of his instruments. He also notes that the engine 4 has shut down but the 4 air intakes work normally, which makes us feel better. After discussing together, we start to think that we probably faced some stratospheric turbulence of very high intensity, our experience in this altitude range being quite limited at that time. But nobody really believes in this explanation. Finally, at subsonic speed, mach 0.9, with all instruments looking normal, we try to restart engine 4 since we still have a long way to go to fly back to Toulouse.

Michel launches the process to restart the engine. It restarts, remains at a medium rotation speed and shuts down after 20 seconds, leaving us puzzled and a bit worried despite the fact that the instrument indicators are normal.

Gilbert then decide to give up and won't try to restart this engine anymore and Claude leaves his engineer station to have a look in a device installed on the prototype to inspect the landing gear and the engines when needed: an hypo-scope, a kind of periscope going out through the floor and not through the roof.

After a few seconds, we can hear him on the intercom:

"Shit! (stuttering) we have lost the intake number 4."

He then describes a wide opening in the air intake, the ramp seems to be missing and he can see some structural damages on the nacelle.

Gilbert reacts rapidly by further reducing the speed to limit even more the dynamic pressure.

But we don't know exactly the extent of the damage. Are the wing and the control surfaces damaged? What about engine 3?

We decide to fly back at a speed of 250 kts at a lower altitude and to divert toward Fairford where our british colleagues and the 002 are based. I inform everybody about the problem on the radio and tell them our intentions. However, I add that if no other problems occur, we will try to reach Toulouse since we still have enough fuel.

Flying off Fairford, since nothing unusual happened, we decide to go on toward Toulouse. All the possible diversion airport on the way have been informed by the flight test centre who follows us on their radar.

At low speed, knowing what happened to us and having nothing else to do but to wait for us, time passes slowly, very slowly and we don't talk much, each one of us thinking and trying to understand what happened. However, we keep watching closely after engine 3.

Personally, I remember the funny story of the poor guy who sees his house collapse when he flushes his toilets. I feel in the same situation.

Gilbert makes a precautionary landing since we don't rely much on engine 3 anymore. But everything goes fine.

At the parking, there is a lot of people waiting for us and, as soon as the engines stop, we can see a big rush toward the nacelles of the right hand side engines.

Gilbert and myself are the first to get off the plane and we are welcomed down the stairs by Andr\xe9 Turcat and Jean Franchi who came out from the crowd watching at the right hand side nacelle.

They both behave the same way, with a slow pace attitude, the same look, a mix of disbelief and frustration.

Andr\xe9 is the first to speak: "I can't believe we were not on this flight, really unlucky\x85". Yes, this flight was supposed to be just a routine flight\x85!

The condition of the nacelle is impressive. We come closer and everybody move aside for us with a look of disbelief and respect as if we were hell survivors.

The ramps of the intake 4, those 2 "dining tables", have completely disappeared leaving a hole where we can see the hydraulic jacks and the stub rod where the ramps were attached.

Indeed, only the ramps were missing, apparently ejected forward which was unbelievable knowing how fast we were flying. The ramp slipped under the nacelle causing some damages on it and on the hood of one of the elevon's servo control. Fortunately, the control did not suffer any damage.

What is left of the rear ramp seems to be blocked down inside the intake in front of the engine and we can see behind it the first blades of the compressor, or what is left of it, not much.

The engine swallowed a huge amount of metal but no vital parts of the aircraft has been damaged, no hydraulic leaks, no fuel leaks. I remembered at that time the stories of some B58 Hustler accident where the loss of an engine at mach 2 almost certainly ended with the complete loss of the aircraft. Our Concorde has only been shaken. This incident strengthened the trust I had in this plane. And I was not unhappy to have experienced this ordeal, especially when I saw the frustration on the face of Andr\xe9 Turcat and Jean Franchi.

But we had to understand what happened and how; and also why the ramp's fixing broke.

It didn't take much time to get the answers.

I unintentionally triggered the problem when shutting down the reheat of engine 3. The sudden stop of the fuel flow did of course stop the combustion and the back pressure behind the low pressure turbine. But, probably because of the modification made on the engine before the flight, the stop of the reheat has not been followed by the normal closing movement of the primary nozzle to compensate the pressure drop. So the low pressure turbine ran out of control, dragging down the low pressure compressor which reacts by surging.

Despite the opening of the spill door, the engine surge led to a sudden movement of the shockwaves in the air intake creating a surge in the intake itself. A similar surge happened in the adjacent intake 4 followed by a surge of the corresponding engine. This caused an excessive pressure above the ramps and the fixings of the intake 4 did not hold.

Since it was the first time we experienced a surge in the air intake, we had little knowledge of the stress it would create on the ramps. This led to miscalculation of the strength of the ramps's frames and they did brake.

Another mistake: instead of installing the motion detectors on the ramp itself, to make the production easier, they have been placed on the arms of the hydraulic jacks. This is why Michel R\xe9tif thought that the position of the ramps were correct. The hydraulic jacks did not suffer any damage and were still working normally even if the ramps were missing.

All the data recorded during this event helped us in redesigning the air intakes and the flight test program resumed three month later.

After this, we deliberately created dozen and dozen of air intake surge to fine tune the way to regulate them with digital calculator this time.

From now on, even if it was still very impressive, it was safe and their intensity was not comparable with what we experienced with the missing ramps.

However, a french president may kept a lasting memory of this, much later, during a flight back from Saudi Arabia. This time, I was on the left side, Gilbert on the right and Michel was still in the third seat\x85 But that's another story.

For me, the lasting impression of failing and being helpless during this incident made me wonder what a commercial pilot would have done in this situation. This plane was designed to be handled by standard commercial pilots and not only by the flight test pilots.

At that time, I was interested in taking in charge the management of a training center for the pilots of the future Airbus's clients. This event pushed me that way and I made it clear that I wanted to add the flight training on Concorde in this project. This has been agreed and I did it.

And the Concorde training program now covers the air intake surges and how to deal with them.

Jean PINET

Former test pilot

Member and former president of the Air and Space Academy

Accueil

This site has a database of thousand of concorde flights with the following datas: Date and time of the flight, airframe used, technical and commercial crews, guests, departure/arrival airports and flight type (regular, charter world tour...).

On top of that, many infos and stories around Concorde can also be found there.

I can't resist to translate one of those stories (I'm far from being a native english speaker or a professional translator; so forgive me for the misspellings and other translation mistakes). It is a report about one of the biggest incident that happened to the prototype 001 during the flight tests:

Shock of shockwaves

We were flying with Concorde at Mach 2 since 3 month already on both side of the Channel. The prototype 001 did outstrip 002 which was supposed to be the first to reach Mach 2.

Unfortunately, a technical issue delayed 002 and Brian Trubshaw fairly let Andr\xe9 Turcat be the first to reach Mach 2 with the 001 which was ready to go.

The flight tests were progressing fast and we were discovering a part of the atmosphere that military aircrafts hardly reached before. With Concorde, we were able to stay there for hours although limited by the huge fuel consumption of the prototypes.

The Olympus engines did not reached their nominal performance yet and, most of the time, we had to turn on the reheat in supersonic cruise to maintain Mach 2.

The reheat is what we call afterburner on military aircrafts. Fuel is injected between the last compressor stage of the low pressure turbine and the first exhaust nozzle. This increases the thrust for the whole engine and its nozzle.

The 4 reheats, one for each engine, are controlled by the piano switches behind the thrust leavers on the center pedestal between the two pilots. Air was fed into the engines through 4 air intakes, one for each engine, attached 2 by 2 to the 2 engine nacelle, one under each wing. The advantage in terms of drag reduction was obvious.

However, tests in wind tunnel showed that, at supersonic speed, if a problem happens on one engine, there was a great chance for the adjacent engine to be affected as well by the shockwave interference from one air intake to the other despite the presence the dividing wall between the two intakes. So we knew that an engine failure at mach 2 would result in the loss of 2 engines on the same side, resulting in a lateral movement leading to a strong sideslip that would likely impact the 2 remaining engines and transform the aircraft into the fastest glider in the world.

This is why an automatic anti sideslip device was developed and installed on the aircrafts.

The air intakes are very sophisticated. At mach 2, it creates a system of shockwaves that slows down the air from 600 m/sec in front of the aircraft to 200 m/sec in front of the engine while maintaining a very good thermodynamic performance. In supersonic cruise, the engines, operating at full capacity all the time, were sensitive to any perturbation and reacted violently with engine surge: the engine refusing the incoming air.

Stopping suddenly a flow of almost 200kg of air per second traveling at 600m/sec causes a few problems. As a result, a spill door was installed under the air intake and automatically opened in such event.

To control the system of shockwaves and obtain an efficiency of 0,96 in compression in the air intake, 2 articulated ramps, controlled by hydraulic jacks, are installed on the top of the air intakes in front of the engines. Each ramp is roughly the size of a big dining room table, and the 2 ramps, mechanically synchronized, move up or down following the instruction of an highly sophisticated computer that adapts the ramp position according to the mach number, the engine rating and other parameters such as skidding.

At that time, it was the less known part of the aircraft, almost only designed through calculation since no simulator, no wind tunnel, did allow a full scale test of the system.

The control of the system was analog and very complex but it was not easy to tune and we were moving ahead with a lot of caution in our test at mach 2.

On the 26th of January 1971, we were doing a nearly routine flight to measure the effect of a new engine setting supposed to enhance the engine efficiency at mach 2. It was a small increase of the rotation speed of the low pressure turbine increasing the air flow and, as a result, the thrust.

The flight test crews now regularly alternate their participation and their position in the cockpit for the pilots.

Today, Gilbert Defer is on the left side, myself on the right side, Michel R\xe9tif is the flight engineer, Claude Durand is the main flight engineer and Jean Conche is the engine flight engineer. With them is an official representative of the flight test centre, Hubert Guyonnet, seated in the cockpit's jump seat, he is in charge of radio testing.

We took off from Toulouse, accelerated to supersonic speed over the Atlantic near Arcachon continuing up to the north west of Ireland.

Two reheats, the 1 and the 3, are left on because the air temperature does not allow to maintain mach 2 without them.

Everything goes fine. During the previous flight, the crew experienced some strong turbulence, quite rare in the stratosphere and warned us about this. No problem was found on the aircraft.

We are on our way back to Toulouse off the coast of Ireland. Our program includes subsonic tests and we have to decelerate.

Gilbert is piloting the aircraft. Michel and the engineers notify us that everything is normal and ready for the deceleration and the descent.

We are at FL500 at mach 2 with an IAS of 530 kt, the maximum dynamic pressure in normal use.

On Concorde, the right hand seat is the place offering the less possibility to operate the systems. But here, we get busy by helping the others to follow the program and the checklists and by manipulating the secondary commands such as the landing gear, the droop nose, the radio navigation, comms, and some essential engine settings apart from the thrust leavers such as the reheat switches.

The normal procedure consists in stopping the reheat before lowering the throttle.

Gilbert asks me to do it. After, he will slowly reduce the throttle to avoid temporary heckler. Note that he did advise us during the training on the air intake to avoid to move the thrust leaver in case of engine surge.

As a safety measure, I shut down the reheat one by one, checking that everything goes fine for each one. Thus I switch off the reheat 1 with the light shock marking the thrust reduction. Then the 3\x85

Instantly, we are thrown in a crazy situation.

Deafening noise like a canon firing 300 times a minute next to us. Terrible shake. The cockpit, that looked like a submarine with the metallic and totally opaque visor obviously in the upper position, is shaken at a frequency of 5 oscillation a second and a crazy amplitude of about 4 to 5 G. To the point that we cannot see anymore, our eyes not being able to follow the movements.

Gilbert has a test pilot reaction, we have to get out of the maximum kinetic energy zone as fast as possible and to reduce speed immediately. He then moves the throttle to idle without any useless care.

During that time, I try, we all try to answer the question: what is going on? What is the cause of this and what can we do to stop it?

Suspecting an issue with the engines, I try to read the indicators on the centre control panel through the mist of my disturbed vision and in the middle of a rain of electric indicators falling from the roof. We cannot speak to each other through the intercom.

I vaguely see that the engines 3 and 4 seem to run slower than the 2 others, especially the 4. We have to do something. Gilbert is piloting the plane and is already busy. I have a stupid reaction dictated by the idea that I have to do something to stop that, while I can only reach a few commands that may be linked to the problem.

I first try to increase the thrust on number 4 engine. No effect so I reduce frankly and definitively. I desperately look for something to do from my right hand seat with a terrible feeling of being helpless and useless.

Then everything stops as suddenly as it started. How long did it last, 30 seconds, one minute?

By looking at the flight data records afterward, we saw that it only last\x85 12 seconds!

However, I have the feeling that I had time to think about tons of things, to do a lot of reasoning, assumption and to have searched and searched and searched\x85! It looked like my brain suddenly switched to a fastest mod of thinking. But, above all, it's the feeling of failure, the fact that I was not able to do anything and that I did not understand anything that remains stuck in my mind forever.

To comfort me, I have to say that nobody among the crew did understand anything either and was able to do anything, apart from Gilbert.

The aircraft slows down and the engine 3 that seemed to have shut down restart thanks to the auto ignition system. But the 4 is off indeed.

Michel makes a check of his instruments. He also notes that the engine 4 has shut down but the 4 air intakes work normally, which makes us feel better. After discussing together, we start to think that we probably faced some stratospheric turbulence of very high intensity, our experience in this altitude range being quite limited at that time. But nobody really believes in this explanation. Finally, at subsonic speed, mach 0.9, with all instruments looking normal, we try to restart engine 4 since we still have a long way to go to fly back to Toulouse.

Michel launches the process to restart the engine. It restarts, remains at a medium rotation speed and shuts down after 20 seconds, leaving us puzzled and a bit worried despite the fact that the instrument indicators are normal.

Gilbert then decide to give up and won't try to restart this engine anymore and Claude leaves his engineer station to have a look in a device installed on the prototype to inspect the landing gear and the engines when needed: an hypo-scope, a kind of periscope going out through the floor and not through the roof.

After a few seconds, we can hear him on the intercom:

"Shit! (stuttering) we have lost the intake number 4."

He then describes a wide opening in the air intake, the ramp seems to be missing and he can see some structural damages on the nacelle.

Gilbert reacts rapidly by further reducing the speed to limit even more the dynamic pressure.

But we don't know exactly the extent of the damage. Are the wing and the control surfaces damaged? What about engine 3?

We decide to fly back at a speed of 250 kts at a lower altitude and to divert toward Fairford where our british colleagues and the 002 are based. I inform everybody about the problem on the radio and tell them our intentions. However, I add that if no other problems occur, we will try to reach Toulouse since we still have enough fuel.

Flying off Fairford, since nothing unusual happened, we decide to go on toward Toulouse. All the possible diversion airport on the way have been informed by the flight test centre who follows us on their radar.

At low speed, knowing what happened to us and having nothing else to do but to wait for us, time passes slowly, very slowly and we don't talk much, each one of us thinking and trying to understand what happened. However, we keep watching closely after engine 3.

Personally, I remember the funny story of the poor guy who sees his house collapse when he flushes his toilets. I feel in the same situation.

Gilbert makes a precautionary landing since we don't rely much on engine 3 anymore. But everything goes fine.

At the parking, there is a lot of people waiting for us and, as soon as the engines stop, we can see a big rush toward the nacelles of the right hand side engines.

Gilbert and myself are the first to get off the plane and we are welcomed down the stairs by Andr\xe9 Turcat and Jean Franchi who came out from the crowd watching at the right hand side nacelle.

They both behave the same way, with a slow pace attitude, the same look, a mix of disbelief and frustration.

Andr\xe9 is the first to speak: "I can't believe we were not on this flight, really unlucky\x85". Yes, this flight was supposed to be just a routine flight\x85!

The condition of the nacelle is impressive. We come closer and everybody move aside for us with a look of disbelief and respect as if we were hell survivors.

The ramps of the intake 4, those 2 "dining tables", have completely disappeared leaving a hole where we can see the hydraulic jacks and the stub rod where the ramps were attached.

Indeed, only the ramps were missing, apparently ejected forward which was unbelievable knowing how fast we were flying. The ramp slipped under the nacelle causing some damages on it and on the hood of one of the elevon's servo control. Fortunately, the control did not suffer any damage.

What is left of the rear ramp seems to be blocked down inside the intake in front of the engine and we can see behind it the first blades of the compressor, or what is left of it, not much.

The engine swallowed a huge amount of metal but no vital parts of the aircraft has been damaged, no hydraulic leaks, no fuel leaks. I remembered at that time the stories of some B58 Hustler accident where the loss of an engine at mach 2 almost certainly ended with the complete loss of the aircraft. Our Concorde has only been shaken. This incident strengthened the trust I had in this plane. And I was not unhappy to have experienced this ordeal, especially when I saw the frustration on the face of Andr\xe9 Turcat and Jean Franchi.