13th Aug 2010, 09:45

permalink Post: 2

Hi Stilton, that is a question that we all used to ask ourselves; not having an APU was a major pain in the butt for the fleet, particularly at charter destinations, where air start trucks, GPU's and air conditioning trucks would all have to be pre-arranged.

One problem with 'Conc' was always one of weight, (for every extra pound you carried, another pound of fuel was required) so any APU installation would have to have been light, and worth the extra weight. But the main problem was one of 'where to put the darned thing. The only suitable space available for an APU was in the tailcone, aft of the tail wheel. Now a ready supply of fuel would have been available either from the aft trim tank, #11, or from one of the two trim galleries. (For stability reasons, tank 11 was invariably left empty during ground transits). The real crunch however, was how to arrange pneumatic services from an APU: Tank 11 was directly forward of the tailcone, so this would have meant either ducting the pneumatics THROUGH the fuel tank (not a particularly good idea ) or externally around the fuselage, which would have been 'draggy' to say the least.

) or externally around the fuselage, which would have been 'draggy' to say the least.

You could still have had an APU powering hydraulics, and in essence electrics too (the emergency generator was powered from the Green System), but without pneumatics for engine starting and air conditioning, it would really have been a waste of weight. Still, it really is a shame that there was no APU.

Historically, there were 'sort of' aux power units fitted to development aircraft: The prototypes had two GTS's (Gas Turbine Starters), one in each nacelle pair, that could start the engines without an air start truck, but these never saw the light of day in later aircraft. The most unusual unit of all was the MEPU (Monogol Emergency Power Unit), located in the tail cone. This was manufactured by Sundstrand, and was fitted to all of the development aircraft. (A derivation of a unit fitted to the X-15!!). The idea was that if you had a four-engined flameout at Mach 2, this thing would fire up, power Green and Yellow hydraulics (plus the emergency generator, again from the Green system), and give you power and control down to a safe relight altitude. The MEPU was powered by Hydrazine rocket fuel (unbelievably unstable) and I seem to remember that the thing would run for about 8 minutes. There was no way that this monstrosity would ever be acceptable on a commercial aircraft, and so a conventional RAT was developed by Dowty for the production aircraft. (Also, the windmilling engines would give you full electrics down to Mach 1.1, and Hydraulics down to about Mach 0.7, so the thing had little practical use when supersonic anyway).

I hope this extended blurb helps answer your query Stilton.

One problem with 'Conc' was always one of weight, (for every extra pound you carried, another pound of fuel was required) so any APU installation would have to have been light, and worth the extra weight. But the main problem was one of 'where to put the darned thing. The only suitable space available for an APU was in the tailcone, aft of the tail wheel. Now a ready supply of fuel would have been available either from the aft trim tank, #11, or from one of the two trim galleries. (For stability reasons, tank 11 was invariably left empty during ground transits). The real crunch however, was how to arrange pneumatic services from an APU: Tank 11 was directly forward of the tailcone, so this would have meant either ducting the pneumatics THROUGH the fuel tank (not a particularly good idea

) or externally around the fuselage, which would have been 'draggy' to say the least.

) or externally around the fuselage, which would have been 'draggy' to say the least.

You could still have had an APU powering hydraulics, and in essence electrics too (the emergency generator was powered from the Green System), but without pneumatics for engine starting and air conditioning, it would really have been a waste of weight. Still, it really is a shame that there was no APU.

Historically, there were 'sort of' aux power units fitted to development aircraft: The prototypes had two GTS's (Gas Turbine Starters), one in each nacelle pair, that could start the engines without an air start truck, but these never saw the light of day in later aircraft. The most unusual unit of all was the MEPU (Monogol Emergency Power Unit), located in the tail cone. This was manufactured by Sundstrand, and was fitted to all of the development aircraft. (A derivation of a unit fitted to the X-15!!). The idea was that if you had a four-engined flameout at Mach 2, this thing would fire up, power Green and Yellow hydraulics (plus the emergency generator, again from the Green system), and give you power and control down to a safe relight altitude. The MEPU was powered by Hydrazine rocket fuel (unbelievably unstable) and I seem to remember that the thing would run for about 8 minutes. There was no way that this monstrosity would ever be acceptable on a commercial aircraft, and so a conventional RAT was developed by Dowty for the production aircraft. (Also, the windmilling engines would give you full electrics down to Mach 1.1, and Hydraulics down to about Mach 0.7, so the thing had little practical use when supersonic anyway).

I hope this extended blurb helps answer your query Stilton.

13th Aug 2010, 18:53

permalink Post: 4

Point taken GF, but it was discovered during development flying that that the Olympus 593 could be relit, given sufficient IAS, at almost any altitude within the normal flight envelope. The variable inlet would even be automatically scheduled, as a funcion of N1, in order to improve relight performance at lower Mach numbers. I certainly agree that you would decelerate and lose altitude fairly quickly under these conditions, however a multiple flame out was never experienced during the entire 34 years of Concorde flight testing and airline operation. There was, as a matter of interest an un-commanded deployment of a Concorde RAT AT MACH 2!! (The first indications of the event were when the cabin crew complained about 'a loud propeller sound under the rear cabin floor'. A quick scan of the F/E's panel revealed the truth of the matter). The aircraft landed at JFK without incident, and the RAT itself, apart from a very small leak on one of the hydraulic pumps, was more or less un-phased by the event. Although it sounds horrific, a prop rotating in a Mach 2 airstream, the IAS it 'felt' would be no more than 530 KTS at any time. The RAT was of course replaced before the aircraft flew back to LHR.

Not quite sure about your reference to the RAT on an F16 being Hydrazine powered; a Ram Air Turbine is just that, using the freely rotatting propellor to power hydraulics, electrics or both. Or do you mean the the F16 has an emergency power unit? Either way, it's fascinating stuff.

Yes, I do remember that the Germans used Hydrazine as a fuel during WW2: The father of one of our Concorde pilots was on an air raid to destroy one o the production plants there, this aviation business is such a small world.

Not quite sure about your reference to the RAT on an F16 being Hydrazine powered; a Ram Air Turbine is just that, using the freely rotatting propellor to power hydraulics, electrics or both. Or do you mean the the F16 has an emergency power unit? Either way, it's fascinating stuff.

Yes, I do remember that the Germans used Hydrazine as a fuel during WW2: The father of one of our Concorde pilots was on an air raid to destroy one o the production plants there, this aviation business is such a small world.

22nd Oct 2010, 09:26

permalink Post: 597

OK guys, here are the answers. If you disagree about any of them then fire away, the old memory certainly 'aint perfect.

As many of you have guessed, there were 22: The 14 production airframes, the 2 production series development aircraft (201 & 202), the 2 pre-production airframes (101 & 102) and the 2 prototypes 001 & 002. PLUS, the major fatigue test specimen at the RAE Farnborough and the static test specimen at CEAT in Toulouse. The CEAT tests actually tested the wing to destruction; I seem to remember it was something like a 200% overload before the wing failed at the root. And great but rather sad pictures

VOLUME

, never seen these before.

OK, from MY memory

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

11:15

The BA193 and BA 195.

OK, there were 12 engine feed pumps (3 per engine) 8 main transfer tank pumps (2 each for the transfer tanks 5, 6, 7 & 8), 4 'A' tank pumps (2 each for 5A & 7A), 8 trim-transfer tank pumps (2 electric pumps each for tanks 9, 10 & 11 PLUS 2 hydraulically driven pumps for tank 9), 4 electric engine start pumps (there was a single electric start pump per engine that delivered fuel to it's own dedicated start atomiser in the combustion chamber. The pump automatically ran when the engine HP valve was set to OPEN and would continue running for 30 seconds after the DEBOW switch was returned to the 'normal' position), 4 engine first stage pumps (a single mechanically driven pump per engine), 4 second stage pumps (a single pneumatically driven pump, sometimes termed 'the turbopump, per engine. This would cut out at around 20,000'), our scavenge tank pump (triggered automatically when there was 7 US gallons in the tank; pumping it back into tank 2. This pump was identical to an 'A' tank transfer pump), and FINALLY, a single de-air pump for tank 10. The pump would drive the fuel through a mesh, removing air bubbles from the fuel. Tank 11 used the L/H trim pump for de-air (similar principle)and would be switched on during take-off. This is why the tank 5 trim inlet valve being set to over-ride OPEN would result in the tank being highly pressurised in the case of the Gonesse disaster; the pump would obviously pressurise the L/H trim gallery and any tank on that side with an open inlet valve!!!

G-AXDN, aircraft 101. (A production wing, fuselage, droop nose and intakes, but with the short tail section and secondary nozzles of the prototypes.

Ready ChristiaanJ? There were 18....Yes, the single SFENA standby horizon, 9 INS gyros (one per X,Y and Z platform in each of the 3 INUs), 8 autostab' rate gyros (one per axis for each of the 2 autostab' computers PLUS a monitor gyro for the pitch axis). The radar by the way used attitude signals from the INS.

9. One per main wheel plus the single 'in flight braking' nose wheel brake.

Mach 0.7!!! Between this and Mach 1.26 the intake surfaces were positioned as a function of engine N1 if the engine was shut down for any reason. (Otherwise of course the intake surfaces were fully up). You needed a sub idle N1 of 57% and below for all this to happen, and it was to assist relight performance and reduce buffet. Between Mach 1.26 and 1.32 the ramps were driven down slightly to about 5%, full supersonic scheduling itself commencing at Mach 1.32.

Already brilliantly answered by Brit312 (as well as the FSLabs diagram). Yep, Geen GO, T/O monitor armed, fuel flow and P7 at or above datum, A/C on ground, reverse not selected and CON light not on. Amber CON (Reheat selected and not detected, N1 OK or reverse selected and primary nozzle (Aj) not at minimum. Blue REV; steady buckets at reverse, flashing buckets in transit.

Fairford, followed by Brize Norton, and then a host of airfields from Prestwick and Shannon to Chateauroux.

OK, probably no surprises now:

Landing - 27L & R, 9L & R (prior to LHR mag' deviation update were 28L & R & 10L & R) together with 23/05.

Take off - 27L (28L), 9R (10R) and 9L. (10L never happened as take offs on this runway only occurred in 2003).

It was FedEx, they planned to operate two stripped out aircraft, leased from BA, between Shannon and JFK as high value parcel carriers. The idea was that parcels would be flown in from all over Europe by small FedEx feeder aircraft and the parcels transferred to Concorde which would then speed on to JFK in around 2 1/2 hours. It never happened because of a combination of economics appraisal by FedEx and BA deciding that it could would not release the aircraft anyway.

A/C 101, G-AXDN first flew on 17th December 1971 with FIXED INTAKES!! (101 was going to be the launch vehicle for the new digital intake control system, but the 'boxes' were still being designed). This placed an operating limit of Mach 1.5 on the aircraft, limiting her ability with such a restricted flight envelope. She returned to Filton in late 1972 for installation of the system, as well as the new Olympus 593-602 engine. (The engine, very similar to the production Mk 610 version, used a quite revolutionary annular combustion chamber, and eliminated at a stroke the thick smoke exhaust that had up to then been Concorde's unwanted visual signiture). The aircraft flew more or less smokeless on 15 March 1973, achieving Mach 2 soon afterwards. As ChristiaanJ pointed out, the British prototype 002 had a similar gap, actually significantly higher, of 19 months. (The French aircraft 001 had an even longer gap of some 20 months).

I hope you guys had fun with this one, regards to all

Dude

Quote:

| 1) How many Concorde airframes were built? |

Quote:

| 2) As far as the British constructed aircraft went, name the destinations that were served?. Regular flight numbers only, excludes charters etc. |

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

, we have: London LHR (duhhh!!), Bahrein BAH, Singapore SIN, New York JFK, Washington IAD, Dallas DFW, Miami MIA, Toronto YYZ, Barbados BGI, and Riyadh RUH. As well as charters being ommited, so are some of the special 'surprise' shuttle appearances that Concorde would make, substituting a subsonic to and from destinations such as Manchester and Edinburgh.

Quote:

| 3) What was the departure time for the ORIGINAL morning LHR-JFK Concorde services? (Not called the BA001 then either). |

Quote:

| 4) Further to question 3 above, what WERE the original flight numbers for the BA001 and BA003? (The morning and evening LHR-JFK services?). |

Quote:

5) There were no less than FORTY SIX fuel pumps on Concorde. What was the breakdown for these? (Clue; don't forget the scavenge pump

).

).

|

Quote:

| 6) What was the only development airframe to have a TOTALLY unique shape? |

Quote:

| 7) This one is particularly aimed at ChristiaanJ. What was the total number of gyros on the aircraft? |

Quote:

| 8) How many wheel brakes? |

Quote:

| 9) What Mach number was automatic engine variable intake control enabled? |

Quote:

| 10) Above each bank of engine instruments were three lights, a blue, a green and an amber. What did they each signify? |

Quote:

| 11) At what airfield were the first BA crew base training details held? |

Quote:

| 12) What LHR runways did Concorde use for landing and take-off? (Trick question, not as obvious as it might seem). |

Landing - 27L & R, 9L & R (prior to LHR mag' deviation update were 28L & R & 10L & R) together with 23/05.

Take off - 27L (28L), 9R (10R) and 9L. (10L never happened as take offs on this runway only occurred in 2003).

Quote:

| 13) What operator had serious plans to operate Concorde from SNN to JFK in the early 1980's? |

Quote:

| 14) What development aircraft did not exceed Mach 2 until fifteen months after her maiden flight? |

I hope you guys had fun with this one, regards to all

Dude

Last edited by M2dude; 22nd Oct 2010 at 11:21 . Reason: oops, misssed out question 2

24th Oct 2010, 23:08

permalink Post: 604

Effect on range of single reheat failure to light on T/O

I understand that you could continue the takeoff if one reheat failed to light, but two questions. if you will:

TC

- Typically, would the balky reheat light on the next event requiring additional thrust, the transonic acceleration?

- In the event it did not relight for the transonic climb, what was the impact on range with only three afterburners available for acceleration?

TC

21st Nov 2010, 18:21

permalink Post: 753

QUOTE]I'm wonder if all 4 Olympus 593 all died in flight and unable to restart. Is it

possible to be able to land at the nearest airport[/QUOTE]

As CristiaanJ says , it depends on how far the nearest airfield was away, but given that there was one close enough then yes in theory it was possible.

On Concorde there were two checklist to cater for a four engine failure that assumes the engine have flamed out but not seized thus the system can be fed by windmilling engines. The two drills are

4 ENGINE FAILURE ABOVE MACH 1.2

4 ENGINE FAILURE BELOW MACH 1.2

When above M1.2 the windmilling speed of the engines should keep the engine generators on line and you should have good hyd pressure also.

Therefore the main point of the drill at this speed is to try and relight the engines, by selecting relight on all 4 engines at the same time. You normally got the chance to go through 2 and some times 3 relight sequences before the speed dropped to Mach 1.2

At mach 1.2 with no engines then the windmilling speed is reaching a point where it is not sufficent to hold the generators on line so the drill concentrates on switching as much of the systems onto essential electrics which will be supplied by the hydraulically driven emergency generator.

To help support the yellow and green hyd system below M1.2 the ram air turbine is lowered. Engine relights will continue to be attempted but as you are on essential electrics now they can only be attempted individually.

If no relights and below 10,000ft then the c/list tells you to prepare the aircraft for landing by lowering nose/visor and gear by emergency systems with speed reduced now to 270 kts. To conserve hyd pressure being mainly derived now from the RAT for the flying controls the emerg gen is switched off during the approach and approch speed is 250 kts with min landing speed

of 200kts

During this all this descent the aircraft had to be flown and navigated, radio calls made along with PA and cabin briefing and all the normall descent checklist complied with so you can imagine it was quite a busy time

This drill used to be practised on the sim ,but the crew would normally find the engines started to relight before 10,000ft so as to give the crew confidence that the drill worked.

However after many years of operation there was some talk about doing away eith the drill as no one could envisage it ever happening. then the BA 747 lost all 4 engines in the volcanic ash cloud and all such talk stopped

possible to be able to land at the nearest airport[/QUOTE]

As CristiaanJ says , it depends on how far the nearest airfield was away, but given that there was one close enough then yes in theory it was possible.

On Concorde there were two checklist to cater for a four engine failure that assumes the engine have flamed out but not seized thus the system can be fed by windmilling engines. The two drills are

4 ENGINE FAILURE ABOVE MACH 1.2

4 ENGINE FAILURE BELOW MACH 1.2

When above M1.2 the windmilling speed of the engines should keep the engine generators on line and you should have good hyd pressure also.

Therefore the main point of the drill at this speed is to try and relight the engines, by selecting relight on all 4 engines at the same time. You normally got the chance to go through 2 and some times 3 relight sequences before the speed dropped to Mach 1.2

At mach 1.2 with no engines then the windmilling speed is reaching a point where it is not sufficent to hold the generators on line so the drill concentrates on switching as much of the systems onto essential electrics which will be supplied by the hydraulically driven emergency generator.

To help support the yellow and green hyd system below M1.2 the ram air turbine is lowered. Engine relights will continue to be attempted but as you are on essential electrics now they can only be attempted individually.

If no relights and below 10,000ft then the c/list tells you to prepare the aircraft for landing by lowering nose/visor and gear by emergency systems with speed reduced now to 270 kts. To conserve hyd pressure being mainly derived now from the RAT for the flying controls the emerg gen is switched off during the approach and approch speed is 250 kts with min landing speed

of 200kts

During this all this descent the aircraft had to be flown and navigated, radio calls made along with PA and cabin briefing and all the normall descent checklist complied with so you can imagine it was quite a busy time

This drill used to be practised on the sim ,but the crew would normally find the engines started to relight before 10,000ft so as to give the crew confidence that the drill worked.

However after many years of operation there was some talk about doing away eith the drill as no one could envisage it ever happening. then the BA 747 lost all 4 engines in the volcanic ash cloud and all such talk stopped

26th Dec 2010, 16:32

permalink Post: 1018

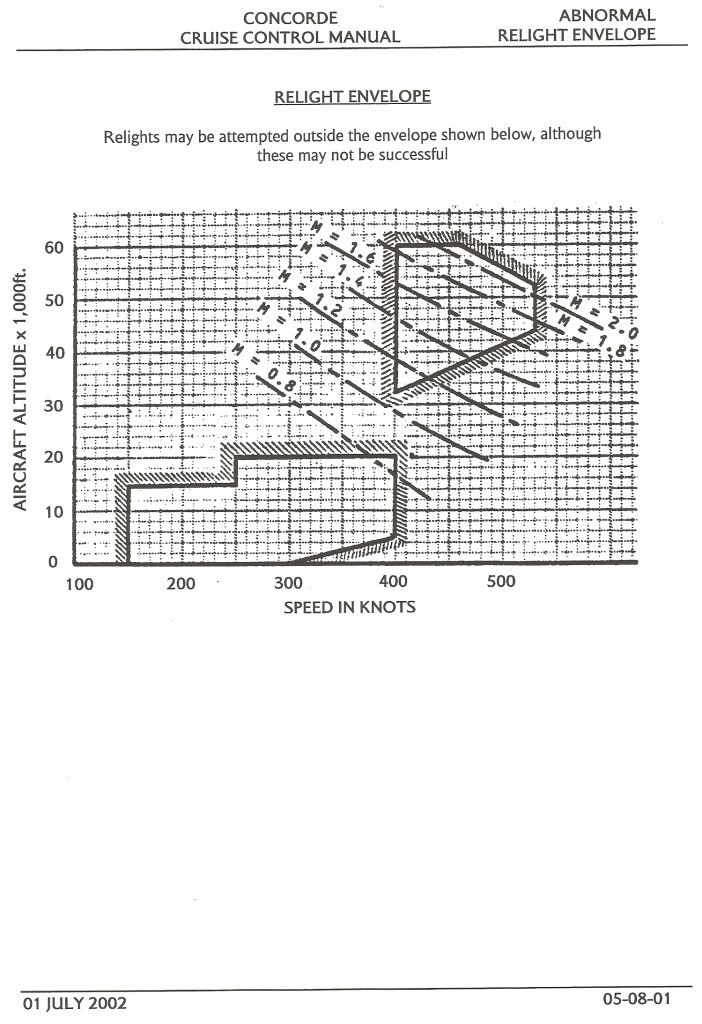

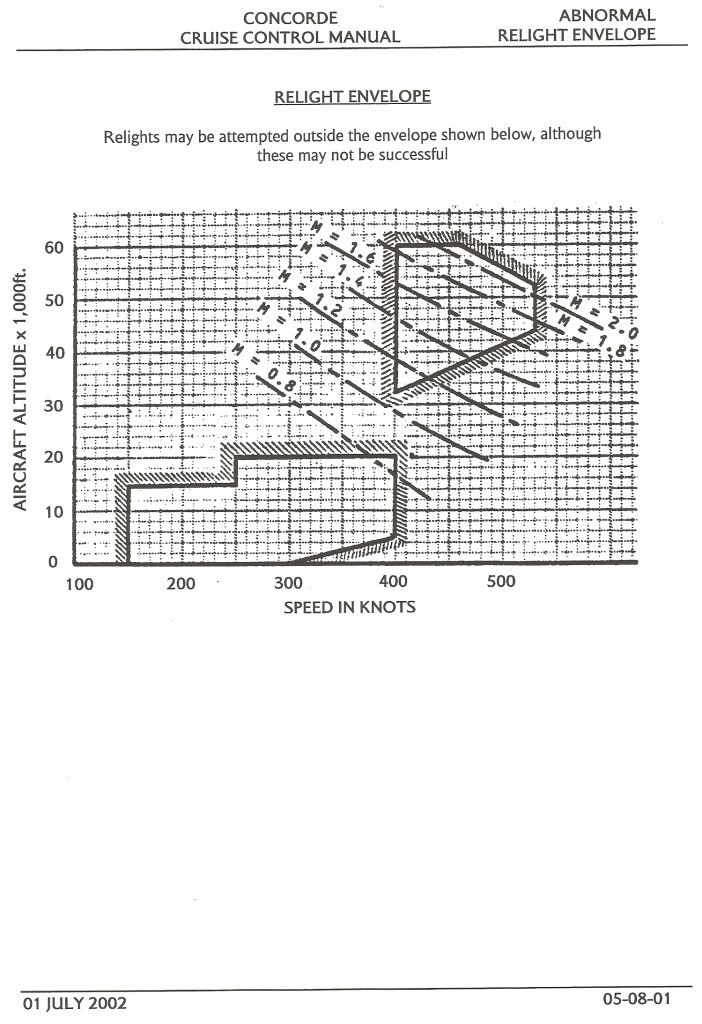

ChristiaanJ - The general shape of the limitations looks very much like the Olympus Relight Envelope.

26th Dec 2010, 17:30

permalink Post: 1019

CAAAD

,

LOL.....

If so, same question.

Can you explain the boundaries of the Olympus Relight Envelope?

Cheers,

CJ

PS : If you have a graph for that, it would be most gratefully received here, I'm sure!

LOL.....

If so, same question.

Can you explain the boundaries of the Olympus Relight Envelope?

Cheers,

CJ

PS : If you have a graph for that, it would be most gratefully received here, I'm sure!

Last edited by ChristiaanJ; 26th Dec 2010 at 18:07 . Reason: Added 'PS'

26th Dec 2010, 21:15

permalink Post: 1021

ChristiaanJ - Upon reflection, I'm not sure that it was the Relight Envelope, but the shape is similar to an engine performance relationship where the 'horse's neck' was referred to.

But the Relight Envelope was established by demonstrating relights during flight testing, on the basis of a theoretical envelope.

There would have been much discussion on the build standard and state of deterioration of engines involved and so on.

Sorry I haven't a copy of the Envelope, but I'm sure it will be in the Flight Manual.

But the Relight Envelope was established by demonstrating relights during flight testing, on the basis of a theoretical envelope.

There would have been much discussion on the build standard and state of deterioration of engines involved and so on.

Sorry I haven't a copy of the Envelope, but I'm sure it will be in the Flight Manual.

27th Dec 2010, 10:38

permalink Post: 1023

CAAAD

From the Cruise Control Manual:

Best Regards

Bellerophon

From the Cruise Control Manual:

Best Regards

Bellerophon

31st Oct 2012, 22:58

permalink Post: 1692

593 smoke reduction

ref question from Joliste

As I was working my way from 1 to 85 I read the above which reminded of a paper I filed 35 years ago:

"Development of Pollution Controls for Rolls-Royce RB211 and Olympus 593 Engines" by A B Wassall. I have picked out stuff relevant to the question:

The engines of the day generated smoke in the primary zone and partially consumed it in the rest of the combustor.

It was easier to reduce the production than increase the consumption but leaning the primary zone had an adverse effect on relight capability which then needed its own corrective action as was done on the 211. Metal temperatures went up with the leaning (as intimated by Joliste)

The 593 did not have the leaning option as it had to maintain an over-rich primary zone at TO to ensure an adequate weak extinction margin when throttled back at completion of supersonic cruise when the combustor had to operate at A/F ratios over 180.

In addition to the smoke problem the combustor weight and pressure loss had to be reduced.

These other two requirements led to the annular combustor and vaporizers which also reduced the smoke substantially. These three benefits were expected based on Pegasus experience.

Quote:

|

why were the Olympus 593 s so smoky to start with, did they use excess fuel to help with cooling as some petrol engines do or was there some design feature which caused the smoke. It seeems to have been cured in later engines

rod |

"Development of Pollution Controls for Rolls-Royce RB211 and Olympus 593 Engines" by A B Wassall. I have picked out stuff relevant to the question:

The engines of the day generated smoke in the primary zone and partially consumed it in the rest of the combustor.

It was easier to reduce the production than increase the consumption but leaning the primary zone had an adverse effect on relight capability which then needed its own corrective action as was done on the 211. Metal temperatures went up with the leaning (as intimated by Joliste)

The 593 did not have the leaning option as it had to maintain an over-rich primary zone at TO to ensure an adequate weak extinction margin when throttled back at completion of supersonic cruise when the combustor had to operate at A/F ratios over 180.

In addition to the smoke problem the combustor weight and pressure loss had to be reduced.

These other two requirements led to the annular combustor and vaporizers which also reduced the smoke substantially. These three benefits were expected based on Pegasus experience.