June 13, 2025, 21:30:00 GMT

permalink Post: 11900873

When designing anything you need to account for unintended consequences and the possibilities for that system adversely affecting safety if it were to malfunction. If you introduced a system designed to prevent flap retraction 20 to 30s after liftoff, what if failure in a channel of that system then prevents flap retraction required to achieve a MACG with critical terrain on departure. We could 'why don't they do this / why don't they do that' until eventually we end up with not flying at all.

On your point of integrated scales, there is a far easier way to cross check actual aicraft weight with calculated weight: a computer that cross references acceleration data on the takeoff run with known values from lookup tables based on specific environmental conditions and engine thrust settings. If you're not accelerating at a normal rate expected for the calculated thrust and weight a warning can be triggered. This was a recommendation echoed by the AAIB following the incident with a Jet2 aircraft getting airborne at only 70% thrust. I believe Airbus and Boeing are looking into the potential implementation of such a safety system.

https://asn.flightsafety.org/wikibase/388602

https://simpleflying.com/aaib-report...f-runway-10ft/

It\x92s worth noting that the acceleration rate was exceptionally low in the TUI event based on the average for that airport. I refer you to my initial post on this thread, it\x92s a risk that there is no config warning horn (to my knowledge) on the B737-800 that will alert the crew, upon selection of TOGA, that the performance solution entered into the FMC does not agree with the actual config. In the case of flap setting, it will only alert if a non standard take-off flap setting is selected. If in the unlikely event TOGA is not pressed at all then\x85..

Airbus have added something of an FWC to their 321NEO aircraft that will alert crew to this - something I\x92d heard from bus mates but wasn\x92t 100% certain on so thanks to those on here that confirmed.

Sorry for further thread derailment, however felt it might be of interest. 787 rated crew on this thread suggest this would form part of the electronic checklist on the aircraft so in the case of the event at hand a red herring.

Last edited by pug; 13th June 2025 at 22:29 .

Subjects

AAIB (All)

Honeywell

TOGA

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 16, 2025, 10:34:00 GMT

permalink Post: 11903315

Quick example, EK 521 accident in DXB:

Subjects

AAIB (All)

AAIB (India)

CVR

DFDR

EAFR

Honeywell

NTSB

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 02:30:00 GMT

permalink Post: 11905658

The main gear retraction/extension is controlled by the center hydraulic system.

It is apparent that the hydraulics failed when the engines shut down after breaking the down-locks and leaving the Main Landing gear bogeys in the tilt position, ready for a next step internal stowage and door closure (that was now never to happen). It is therefore apparent that the dual engine failure and consequent automated RAT extension was precipitated by this gear selection or retraction cycle and thus likely to be either WoW micro-switch or 5G Radar altimeter-effect associated. Due to accumulator depletion, the electric pump load would have spiked to replenish it. This may have precipitated the dual engine shutdown due to an unfiltered electrical surge affecting the Ground/Air microswitches (or a local 5G transmission affecting the RADALT) and resetting the TCMA.

The RADALT? Another plausibility? Because of the furore over a spasticated frequency allocation by the US FCC, the US FAA had finally “bought in” and declared that individual nations and their airline operators were responsible for their own 5G frequency spectrum allocations and for taking essential steps to ensure mitigation of the interference effects upon aircraft automated landings and other critical systems caused by their own national approved 5G spectrum decisions. It was admittedly a situation calling for extensive modifications to (and shielding for) the three radar altimeters fitted for redundancy considerations to all modern airliners... for Category 3 ILS approach and landing in zero/zero visibility conditions. The RADALT also features in many air-ground sensing applications. (eg the 747-8).

This was an unusual FAA “passing of the buck” to manufacturers such as Honeywell etc. (to sort out with client operators). But then again, it was not the US FCC’s right to dictate the specific 5G frequencies internationally. These spectrum allocations now vary over the wide selection of 5G phones available (and also nationally). 5G Radar Altimeters constitute a part of the ground/Air sensing that changes the TCMA from ground mode (able to fuel-chop engines) to the air mode (inhibited from doing so)... Ground activation is acceptable ...where fuel chopping of uncommanded thrust can prevent runway sideways excursions or runway length overruns. The question now becomes: “Is it more (or less) safe having an automated fuel-chopping capability on BOTH your left and right, rather than leaving it to the pilot to react via his center console fuel cut-off switches... in the unlikely event of a runaway engine after landing (or during an abandoned take-off)?

5G Frequency Variations

The frequencies of 5G phones vary nationally based on the frequency bands allocated and used by different carriers in each country. In the United States, for example, carriers such as AT&T, Verizon, T-Mobile, and others use a combination of low-band, mid-band, and high-band 5G frequencies. Low-band 5G frequencies typically range from 600 MHz to 1 GHz, mid-band 5G frequencies range from 1.7 GHz to 2.5 GHz, and high-band 5G (mmWave) frequencies start at 24 GHz and go up to 40 GHz . These frequencies are allocated by regulatory bodies such as the Federal Communications Commission (FCC) and can vary between countries based on spectrum availability and regulatory decisions. In other countries, the specific frequency bands used for 5G may differ, leading to variations in the frequencies supported by 5G phones. Additionally, the deployment of 5G networks can also influence the frequencies used, with some countries focusing more on sub-6 GHz bands while others prioritize mmWave technology.

5G interference? It may be an avenue worth exploring?

Subjects

Dual Engine Failure

Engine Failure (All)

Engine Shutdown

FAA

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

RAT (All)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 12:01:00 GMT

permalink Post: 11905926

Subjects

Condolences

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 12:21:00 GMT

permalink Post: 11905944

Subjects

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 15:52:00 GMT

permalink Post: 11906088

For the avoidance of doubt, the above is a technical observation on the switch type NOT a causation theory for this accident.

Subjects

Condolences

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 17:05:00 GMT

permalink Post: 11906149

Not looking over my shoulder here but I should add that I know and respect Honeywell switches. Those I have worked with are well designed and well made plus Honeywell incorporate improvements based on field experience. As posted by another contributor upthread I am puzzled by the odd ‘down’ = engine off configuration though.

Last edited by Europa01; 19th June 2025 at 17:36 .

Subjects

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 17:12:00 GMT

permalink Post: 11906161

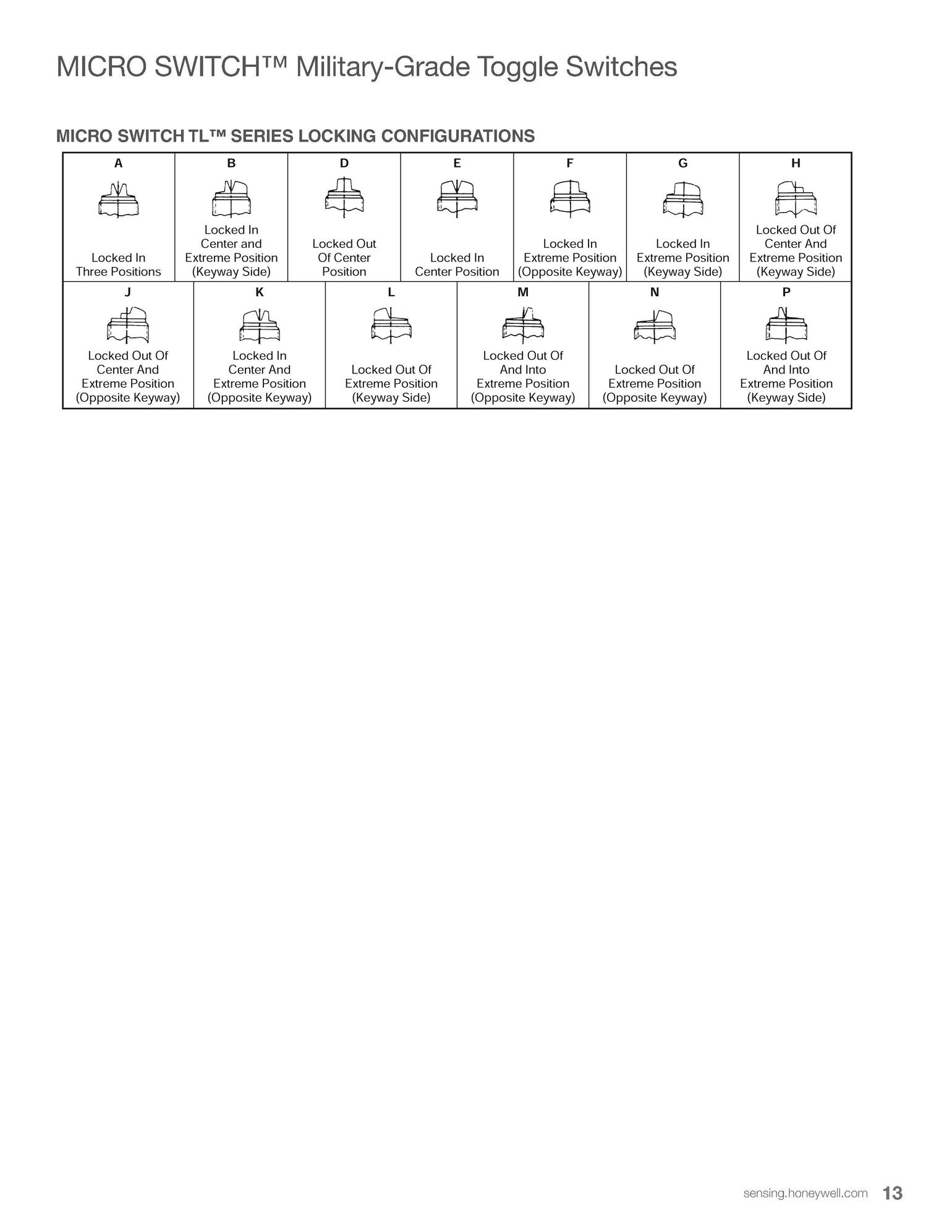

That's a TL series switch with 4 poles (the "4" in "4TL"), a "type D" lock (meaning locked out of centre position per the Honeywell data sheet - the "D" in "3D." This is a photo of one:

You can find the manufacturer's datasheet here: https://octopart.com/datasheet/4tl83...ywell-25749542

Problems with critical switches aren't new on 787-8s. For instance, in addition to the SAIB above, there's this AD: https://www.federalregister.gov/docu...pany-airplanes

Looking at the photo above, it isn't just wear that's potentially an issue, but foreign object impingement. There don't appear to be gaitors fitted to these switches in the 788, so the locking mechanisms are potentially susceptible to a build-up of material if not kept clean. There are a range of other failure modes possible, whilst the SAIB specifically describes found-in-the-field problems with these switches.

Yes, they're chunky, and very positive when new. That doesn't mean they shouldn't be discussed.

Subjects

Air Worthiness Directives

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 20:01:00 GMT

permalink Post: 11906272

Not looking over my shoulder here but I should add that I know and respect Honeywell switches. Those I have worked with are well designed and well made plus Honeywell incorporate improvements based on field experience. As posted by another contributor upthread I am puzzled by the odd \x91down\x92 = engine off configuration though.

Subjects

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 19, 2025, 21:52:00 GMT

permalink Post: 11906364

That's a TL series switch with 4 poles (the "4" in "4TL"), a "type D" lock (meaning locked out of centre position per the Honeywell data sheet - the "D" in "3D." This is a photo of one:

You can find the manufacturer's datasheet here: https://octopart.com/datasheet/4tl83...ywell-25749542

Problems with critical switches aren't new on 787-8s. For instance, in addition to the SAIB above, there's this AD: https://www.federalregister.gov/docu...pany-airplanes

Looking at the photo above, it isn't just wear that's potentially an issue, but foreign object impingement. There don't appear to be gaitors fitted to these switches in the 788, so the locking mechanisms are potentially susceptible to a build-up of material if not kept clean. There are a range of other failure modes possible, whilst the SAIB specifically describes found-in-the-field problems with these switches.

Yes, they're chunky, and very positive when new. That doesn't mean they shouldn't be discussed.

Subjects

Air Worthiness Directives

Honeywell

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 09, 2025, 20:05:00 GMT

permalink Post: 11918581

Edit: And here it is:

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 09, 2025, 22:34:00 GMT

permalink Post: 11918651

Edit: And here it is:

For those unfamiliar with cockpit controls in general, I\x92ll leave my \x93schematic\x94 image to show the principle of \x93lift-and-move\x94 the toggle vice just pushing the toggle in a desired direction.

Cheers,

PJ2

Last edited by PJ2; 9th July 2025 at 22:45 . Reason: for context

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 11, 2025, 23:17:00 GMT

permalink Post: 11919895

The Boeing Company (Boeing) received reports from operators of Model 737 airplanes that the fuel control switches were installed with the locking feature disengaged. The fuel control switches (or engine start switches) are installed on the control stand in the flight deck and used by the pilot to supply or cutoff fuel to the engines. The fuel control switch has a locking feature to prevent inadvertent operation that could result in unintended switch movement between the fuel supply and fuel cutoff positions. In order to move the switch from one position to the other under the condition where the locking feature is engaged, it is necessary for the pilot to lift the switch up while transitioning the switch position. If the locking feature is disengaged, the switch can be moved between the two positions without lifting the switch during transition, and the switch would be exposed to the potential of inadvertent operation. Inadvertent operation of the switch could result in an unintended consequence, such as an in-flight engine shutdown.

...The table below identifies the affected airplane models and related part numbers (P/Ns) of the fuel control switch, which is manufactured by Honeywell.

...787-8, -9, and -10

Last edited by 13 others; 12th July 2025 at 02:40 . Reason: Bold emphasis mine, fixed link

Subjects

Engine Failure (All)

Engine Shutdown

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

SAIB NM-18-33

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 00:28:00 GMT

permalink Post: 11919993

Why don't you read the data sheet for the switch series and count the number of references to "toggle switch" in the description.

https://octopart.com/datasheet/4tl83...ywell-25749542

Subjects

Fuel (All)

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 00:40:00 GMT

permalink Post: 11920009

Subjects

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 10:01:00 GMT

permalink Post: 11920385

Honeywell Switch Gate Configurations (Ref: honeywell_hwscs06627_1-1735572)

This extract from the datasheet of the Honeywell switch installed in the B787 for switching between Cut Off and Run shows the various gates that can be incorporated in such a switch. I suspect that it is Configuration D which allows the switch to be in one or other of only 2 positions. But the centre gate has a relatively wide flat table on which the switch can rest if it is not moved correctly to either the Run or Cut Off position. I therefore think that it is not beyond the realm of possibility that both switches may have initially been resting on the gate and then slipped into the cut off position during take off. However, what militates against this theory are the words of the challenge, "Why did you do that?" suggesting that one pilot had seen the other pilot actually flip the switches.

Subjects

Fuel (All)

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 10:41:00 GMT

permalink Post: 11920436

Subjects

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 11:26:00 GMT

permalink Post: 11920464

I could hardly figure what the "disengaged" word meant in this context, so I did a Google search for the switch part numbers (especially "766AT614-3D") to figure the difference between them, and a page from this chinese web site was part of the results.

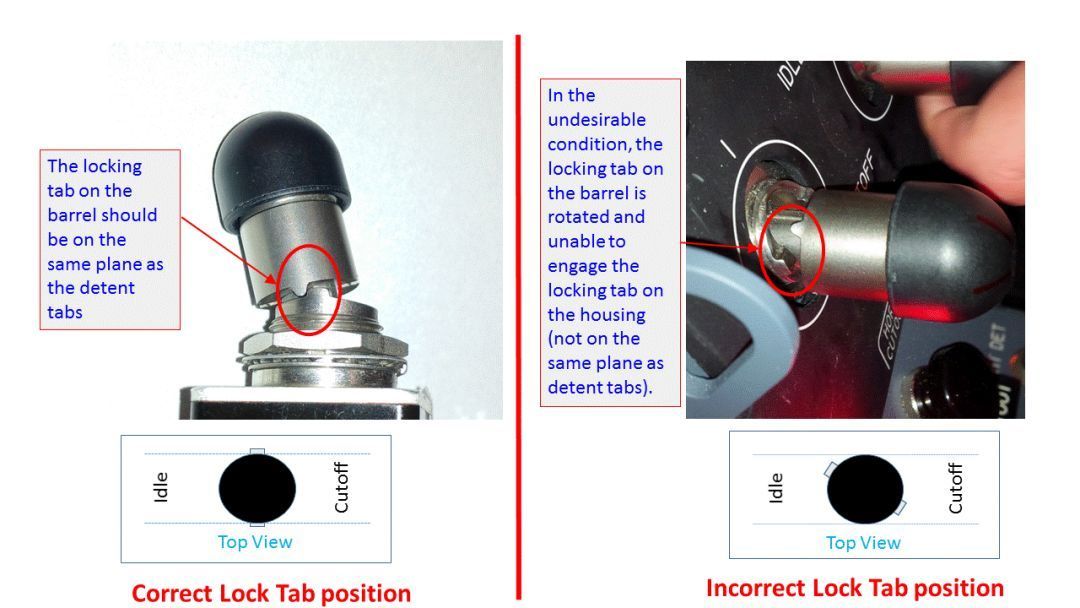

And while I was painfully crawling the thread, I noticed the following picture about an "undesirable condition":

Incorrect lock tab position on fuel cut-off switch

If this incorrect mounting is actually possible, it would possibly remain unnoticed from the pilots (normal "pull-up then move" action is unaffected), but it would cancel the protective function of the so-called "locking tab", and even limit the travel of the switch handle in both directions, making it more vulnerable to an undesired change of state.

The photos above seem convincing enough, but I'd be very grateful for an informed opinion on this assembly mistake. Even if this is possible, the probability of both switches being unexpectedly snapped seems very remote to say the least, but not as remote as previously estimated.

One other useful thing from that web site is a partial schematic which shows the connection of the 4 poles in the switch. I believe this is from a 737NG but it should be the same idea.

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

SAIB NM-18-33

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 11:43:00 GMT

permalink Post: 11920472

One other useful thing from that web site is a partial schematic which shows the connection of the 4 poles in the switch. I believe this is from a 737NG but it should be the same idea.

If any of that were true why would it happen after Vr and why would one pilot ask: \x93why did you go to cutoff\x94. That is an observed deliberate action. Cmon folks enough with the nonsense!

Why are people shying around the truth!?

Subjects

Honeywell

SAIB NM-18-33

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 12, 2025, 21:04:00 GMT

permalink Post: 11920795

One other useful thing from that web site is a partial schematic which shows the connection of the 4 poles in the switch. I believe this is from a 737NG but it should be the same idea.

b79edb16af_5b3bb7a57d07fbf3c85529ab3f52308b609d82a3.png.webp

Last edited by RomeoTangoFoxtrotMike; 12th July 2025 at 21:28 .

Subjects

Honeywell

SAIB NM-18-33

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.