June 16, 2025, 01:57:00 GMT

permalink Post: 11903735

If the engine doesn't continue normal operation, that's considered a 'fail'. Plus, the engine reaction of an over-rotated inlet (inlet separation) is a surge - accompanied by big bang and a ball of flame out the back.

Nothing we know about this accident supports an over-rotation and related engine stall/surge.

Going back to your prior comments on FADEC and TCMA; these are independent systems to each engine, however the event indicates a symmetric loss, and the potential of water ingress from a failed E/E sealing from the main cabin services remains a single causation that could result in multiple failures at the same moment. The last time I assessed issues in the E/E bay related to unauthorised inflight access to the fwd E/E of a B777 it was sobering how many irreversible conditions could arise. The B744 water inundation cases I was involved in were both on TO, the QF event was during deceleration. We are looking at vectors that come from outside of the normal assumptions in the SSA's, water fits that bill.

Subjects

FADEC

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 16, 2025, 07:34:00 GMT

permalink Post: 11903745

Subjects: None

The thread is closed so there are no user likes are available and no reply is possible.

June 16, 2025, 07:44:00 GMT

permalink Post: 11903746

Source: https://www.thetimes.com/world/asia/...rash-vhqw6b7v3 (paywalled)

1250m from the end of the runway, between high speed C and D, adjacent to the closed high speed.

There is nothing unusual with the rate of acceleration that is observable ninth video. You can work that out using google earth and the Indian AIP and/or state airport charts. The weight of the plane can be estimated by the flight time and pax load and an allowance for cargo. The simplified TO performance is in the inflight performance section of the FCOM, which you may find a copy on line.

The aircrafts rotation has no obvious issues, until a few seconds after achieving an attitude that is consistent with the V2+15-25 range, at which point the ROC visibly starts to decay.

Subjects

FCOM

Takeoff Roll

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 16, 2025, 23:32:00 GMT

permalink Post: 11903843

Let me explain.

The consensus is that both engines quit shortly after liftoff (that assumes that the RAT did in fact deploy). At least one of the data recorders has battery backup, so it should have kept functioning when all aircraft power was lost.

However...

Over the years, I've looked at lots and lots of digital flight data recorder outputs when investigating some sort of incident or other engine anomaly, So I have become rather familiar with some of the interesting characteristics of DFDR data.

On the 767 and 747-400, when you shutdown an engine and the IDG goes offline, there is a momentary 'glitch' in the electrical power system as it reconfigures for the available power source - this is why you see the flight deck displays flicker and return, and the cabin lights momentarily flicker. As a result, most of the avionics boxes 'reset' - this is quick, but it's not instantaneous. This shows up in the FDR data - sometimes as 'no valid data' for a few seconds, or as garbage readings of zero or 'full scale'. Now, looking at the FDR data, it's easy to simply disregard the data, so normally no big deal.

Starting with the 777 (and on the 787 and 747-8), this electrical power glitch was 'fixed' - there is slight delay (~quarter of a second IIRC) before the fuel cutoff signal is sent to the engine - during which the electrical system reconfiguration takes place so no more 'glitch' during a normal engine shutdown...Except whatever happened to these engines wasn't 'normal'.

If there is a fuel cut at high power, the engine spools down incredibly rapidly - a second or two from max power to sub-idle. Assuming the fuel cut wasn't commanded by the flight deck fuel switches, the electrical system won't know it's coming, so it can't reconfigure until after the engine generators drop offline - and you're going to get that power glitch. Nearly every avionics box on the aircraft will reset due to this electrical glitch, and the FDR isn't going to get useful data for a few seconds (and then, only from the stuff that's on the battery bus).

Whatever happened, happened quickly - it's quite possible that whatever initiated the high-power fuel cut didn't get recorded.

If the cause is what I have suggested it will dificult to get direct evidence of that case, as it was for the QFA072 event as well. Like icing cases, a water ingress into the avionics is going to be a tough investigation, water would have been sprayed all over the wreckage in the aftermath. Dousing the E/E bay with 20 or 30 gallons of water will be an expensive investigative exercise to do in a real plane, with engines running. Would not want to be observing up close.

Subjects

CVR

DFDR

FDR

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Generators/Alternators

RAT (All)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 17, 2025, 10:44:00 GMT

permalink Post: 11904149

so nothing to contribute but a query. I've read the first thread since it started and then this one and the best suggestions I've seen which seem to fit multiple failures at rotate and shortly after (gear mid cycle or failed hydraulics, RAT out, emergency lights on, lack of thrust) involve some catastrophic failure in the electrical systems. My query is will the investigators be able to establish this, are there environmental sensors in the EE bays which might detect and record water presence (steam, excessive humidity) before there are cascading and otherwise unrelated failures in a variety of systems.

Obviously a long term leak would leave corrosion residue but a recent burst build-up with a dam overwhelmed at rotate might be more difficult.

Re E/E environmental, no sensors incorporated, and they probably would not help in the type of problem that I have concerns with. The crew get an idea of a problem as multiple systems fail at the same time from water inundation. This is way outside of the DO-160-G requirements taht the electronics are certified to. Pouring a kiddy pool worth of water that is sitting above the bay in the moisture barrier awaiting a suitable opportunity to become evident is outside of expected behaviour, but has happened at least 3 times with major impacts on other aircraft.

Subjects

RAT (All)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 17, 2025, 11:12:00 GMT

permalink Post: 11904166

....

Rotate vs. Air/Ground Switching Vs Pilot action

(This is my take, it might seem counterintuitive, if you know better help) On a normal takeoff at rotation, liquids don't slide backward any more than they do during the takeoff roll itself. They slide back during the takeoff roll, and at rotation, there's actually a slight reduction in those backward forces. The main force is still pushing them back, but because the wings are now generating lift, there's more drag than when the plane was just rolling on its wheels. So, if liquids have pooled at the back of something at rotation, during and just after that maneuver, they'll actually ease forward a bit. The main force is still pushing them back, but it's less so. My take is if something sudden happens around rotation, I think it's probably more connected to something like the air/ground sensing or pilot action, but it is still possible that pooled liquids sloshing forward a little could also cause it.

Pilots have to do a few things at rotate time, pull back in the controls, not the thrust levers in error and then move the landing gear lever. Over the years there's been a few action slips, so unintended control movements.

Subjects

Action slip

FDR

Gear Lever

Takeoff Roll

V2

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 18, 2025, 13:59:00 GMT

permalink Post: 11905220

The Boeing 787 has (I read) over 30 million accumulated flight hours on the fleet. And just the one accident in which there was a lack of adequate thrust after TO. Whatever happened is, just from these two numbers alone, "extremely remote" in Lloyd and Tye's ageless words from 43 years ago. Trying to perform any kind of probabilistic assessment on that is for the birds (to use my ageless words).

For those who wish for a bit more:- Twenty-two years ago, Kevin Driscoll (Honeywell's bus guru and Byzantine failure guru, now retired) and his coauthors published an account of a Byzantine failure mode on a common transport aircraft (unnamed, but it is one that many people here fly) which almost led to its grounding. A relevant quote from Section 5.4: "I n this case, each Byzantine fault occurrence caused the simultaneous failures of two or three “independent” units. The calculated probability of two or three simultaneous random hardware failures in the reporting pe riod was 5 x 10^(-13) and 6 x 10^(-23) respectively. After several of these incidents, it was clear that these were not multiple random failures, but a systematic problem. The fleet was just a few days away from being grounded, when a fix was identified..... " Note those were tiny tiny probabilities derived by engineers who specialise in such calculations from hardware reliability data. Even when you are very, very good at it, probabilistic reasoning of this sort is not necessarily a helpful guide to predicting or analysing "extremely remote" but actual events.

PBL is a globally recognised authority on complex faults, and his teams papers are great reading. He is also associated with the Functional Resonance work from Erik Hollnagel. FRAM does not reduce the workload for SMS managers, but it has the potential to increase the reliability through understanding how our systems work. PBL W-B analysis is elegantly simple but gives complex system understanding in a logical manner.

Subjects: None

The thread is closed so there are no user likes are available and no reply is possible.

June 20, 2025, 05:31:00 GMT

permalink Post: 11906581

The state is not yet required to report more than the preliminary report IAW Annex 13, however, the observations that are readily available to the investigators and the OEM teams will not be conducive to good nights sleep by any of them.

The regulator is not in a position to make an EAD or other airworthiness directive without a justifiable basis, and the very fact this is suggestive of a failure mode that is catastrophic, even though obviously low probability doesn't permit the risk to be accepted. With the system architecture on the B787, if viewed as a Bayesian assessment, the highest probability remains an environmental item outside of the design as approved. The problem with that area as we have seen before, it is very difficult to prove events with icing (Roselawn etc) or moisture ingress in most cases, it will likely require a forensic teardown of the control systems of the engine to determine what damage may have occurred before impact. That is a daunting proposition when the area involved has been at the center of the impact and post impact fire. I have more confidence in the systems engineers and software than the ability to maintain an environment that does not cause adverse outcomes.

Subjects

Annex 13

Preliminary Report

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 21, 2025, 02:04:00 GMT

permalink Post: 11907425

My airline\x92s manuals don\x92t go into much detail, but I read on another site that if both the center tank pumps fail, the engine driven pumps aren\x92t able to suction feed well enough from the center tanks to sustain engine operation. If there was fuel in the center tanks, a complete electrical failure would soon lead to center tank fuel pumps failure (all fuel pumps failure as stated previously) and fuel starvation of both engines. A rescue from this situation would be an immediate selection of both center tank fuel pumps OFF (not if my airline\x92s non-normal checklists) and waiting for successful suction feed from the L and R main tanks to occur, this would take a number of seconds.

If you go and chat to the engineers, have a look in the IPC or MM I Ch 28, you should find a good description of the fuel boost pumps. It's been a while but I recall they are Eaton designs, the general arrangement is similar to the B777. They both have a suction feed that permits fuel feed in the event of a loss of all boost pumps. The only impact of that arises at high altitude and high thrust levels, where the engine driven fuel boost pumps may capitate and reduce the available fuel feed resulting in a lower thrust level.

Refer page 12.20.02 in the TBC's B787 FCTM, or search for "SUCTION FEED".

At sea level, full thrust will be achieved without any boost pump on the aircraft. Recall that the CWT boost pumps are known as Override boost pumps, they are feeding from the CWT when there is fuel and they are running, as the output pressure is higher from these pumps than the 2 wing boost pumps. Whether there is fuel in the CWT or not, or the CWT pumps are energised, is immaterial to whether fuel will be supplied to the engine driven fuel pumps.

Note that with BA038, the fundamental problem was blockage of wax/ice formed in the piping that blocked the FOHE, and that will cause a problem with those engines that have such architecture, but is not associated with the availability of the boost pumps themselves. Even then, the engines did not technically fail, as they have both done simultaneously with the B788 of AI 171, BA's engines were running but not able to provide significant thrust due to the FOHE blockages.

Subjects

Centre Tank

Electrical Failure

Fuel (All)

Fuel Cutoff

RAT (All)

RAT (Deployment)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 22, 2025, 01:10:00 GMT

permalink Post: 11908171

On departure at these weights the aircraft would have some assumed temperature thrust reduction from max available on the GEnx -1B70, Unless they were carrying lead, they were around 30,000 or more below the limit weight for a flaps 5 TO. At that weight, around 440k lbs, they would have had a fair OEI climb gradient on one engine, certainly a positive gradient with the gear down, so they lost more than 50% of total thrust. There is no yaw or roll, or inputs to counter a yaw or roll moment so the aircraft was symmetrical at all times, that means losing absolutely no less than 50% of total available thrust at that point on each engine. At 50% reduction. the aircraft would have continued a positive gradient with the gear down and the flaps at the TO setting. It did not, it decelerated at around 1meter sec, or 0.1g deceleration for just maintaining level flight, but it also had to descend and that was worth around 0.05g as well. Instead of having any positive thrust margin, the guys were needing to descend to balance the decrement in thrust of around 0.15g, and that means it has negligible to no thrust from the engines. The full analysis takes more effort as the AOA has increased over the 15-20 seconds to impact, which is increasing the drag of the aircraft rapidly towards the end. For the first 5-10 seconds however, it is not such a great change, but it is still increasing.

In level flight, the aircraft would accelerate level at around 0.3-0.4g gear down with both engines running at max chuff. Lose one, and you are back to 0.05-0.1g or so. These guys had far less than one engine remaining, gravity was all that they had going for them.

To that end, there is no requirement to have the EAFR readout of the N1, N2, FF, or EGT, the video shows they had no puff going worth a darn. That is basic back of the envelope physics and anyone who does aircraft performance testing would be able to get that answer straight from the video without using a calculator, by the time they had watched the video a couple of times in replay.

I have no qualms on stating that the engines are not operating, the RAT, gear tilt are consistent with the dynamics of the aircraft. This is far simpler to determine the energy state than that of the B738W at Muan, the lack of early video required a couple of iterations of the kinetic energy of the aircraft at Muan to end up with a probable flight path, and most likely estimate of the thrust remaining for those most unfortunate souls.

regards,

FDR

Last edited by fdr; 22nd June 2025 at 16:01 .

Subjects

EAFR

FDR

GEnx (ALL)

RAT (All)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 30, 2025, 04:37:00 GMT

permalink Post: 11913337

The 787 batteries are also in separate EE bays. Main one in the front and the dedicated APU battery in the power electrics bay aft of the landing gear.

They are both contained in fireproof boxes that will vent to atmosphere in the event of a thermal runaway.

I have been working on 787s for over a decade and leaks from gallies and lavs has not once been on my list of snags.

When pax flush clothing and other rubbish down a vacuum toilet system, the potential for stuff to not work as advertised is not zero.

Subjects

APU

Air Worthiness Directives

Condolences

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 01, 2025, 00:39:00 GMT

permalink Post: 11913950

Subjects

Dual Engine Failure

Engine Failure (All)

FADEC

RAT (All)

RAT (Deployment)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 01, 2025, 00:59:00 GMT

permalink Post: 11913958

- There is zero reason for the engines to have to be DOA before rotate. A point of note will be a close look at the elevator deflection at rotate, and that alone would put paid to such a position.

- The engines being lost shortly after rotate is consistent with the video from the NE met sensor camera.

- Determining the liftoff point by ADSB without adding a correction for the flow change at the PS sensor due to AOA is going to give nonsense, and that appears to be the case. The video gives a fair, not brilliant geometry to shoot a transit sighting of the aircraft at liftoff, and that is before the point that GT states.

- I am impressed that GT has the deceleration rates for a B787 gear down, flaps at 5, for zero thrust. I know what it is for gear up, gear down, not so much, but it will be on the prompt side of ugly.

- Undertaking an MLE estimate of the kinematics, do add the change for AOA if assuming a deceleration rate. You can get away with a rough overall estimate, but then lets not "gild the Lilly" by assuming accuracy at the decimal point level.

- Every sensor has measurement errors, position errors, and granularity factors when converting to an output, accuracy to multiple decimal points just looks tacky.

- The weight of the aircraft, if it is within +/-2% of the actual is doing pretty well, we have analysed baby puppy FAA aircraft that alter their actual weight by over 6% depending on whether they are using EASA weights for PLD, or FAA, or maybe the aircraft just happen to suffer from Coriolis.

- GT's heart is in the right place, I don't agree with much of what he says, but then my wife doesn't agree with me often either, so maybe that is inconclusive.

For the past 30 years, we have collectively bagged Boeing in increasing measure, for doing what all corporations are obliged to do; the board is answerable to the investors, and the investors have a "10-second Tom" event horizon when it comes to their earnings. It is little wonder that the race to the bottom is being won by Boeing, it is what Wall Street demands, and in the end, after the bones of the OEM are picked clean by those that do such things on the carcasses of once great US engineering giants, then they will bitch and moan about the losses to shareholders while they pocket the profit of their profession, fleecing the investors. L-M has been better in managing the milking of the public purse, and maybe that is the way it should be.

Subjects

ADSB

FAA

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 17:34:00 GMT

permalink Post: 11919133

- There is no thrust lever interlock to the fuel control switch function. Don't know of any Boeing design that has that, nor Airbus, but the comment on the MD11 may or may not be valid. MDD had some odd functions in different systems, some good, some, less so.

- Switching off the fuel control switches gives an immediate shutdown, at any time.

- The rumour seems to be quite bizarre, as it presumes that as the aircraft is being rotated, (it still has symmetric thrust at that point) presumably someone with extra sets of hands turns off both fuel control switches, simultaneously. That is a 2 handed action. We are to assume that someone leans over and grabs both switches without the knowledge of the pilot who has at a minimum one hand but procedurally two hands on the control column?

I am no longer interested in being a witness to the abuse of anonymity that arises on this thread.

cheers

Subjects

Fuel (All)

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 13, 2025, 03:44:00 GMT

permalink Post: 11920995

There is one known inadvertent shutdown with this type of switch, on a B744, many years ago, when the Rosen visor fell from the upper sun visor rail when being relocated. That managed to turn off 1 fuel switch.

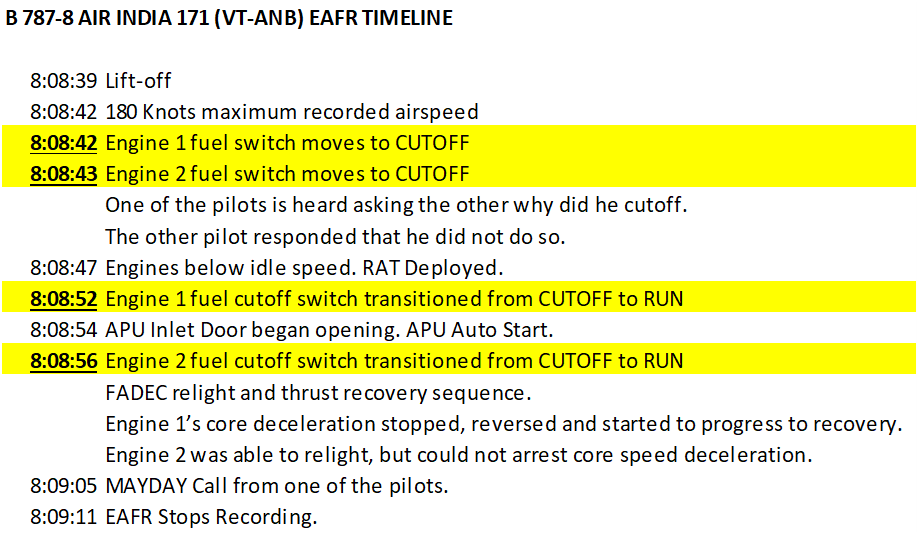

The report is quite comprehensive for an interim report, and it does not draw any conclusions as yet as to how or why the fuel control discrete is recorded as OFF, however, it is troubling. I would reserve opinion until there is a clear spectral analysis that shows the selection of the fuel switches off, and then back on.

As to the time to react, the crew in this case if unaware of the causation will have a fair recognition time to assimilate the information that is presented, and then to determine that the cause is the switches being off is going to take some time to process, discover the system status and respond, if that is what happened. I remain concerned with liquid ingress to the control system, giving a change in the sensed switch position rather than the selected position. That is looking like a long shot, but then this event is way outside of the normal box.

Subjects

AAIB (All)

FADEC

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 13, 2025, 18:40:00 GMT

permalink Post: 11921477

I have a couple of questions. Forgive me for being late into this thread if any of them is already discussed:

1) I just read this in a Boeing manual:

- They send signals to the remote data concentrators (RDC) and the spar valve start switch relays.

- The spar valve start switch relays use these signals to control the spar valve and the high pressure shut off valve (HPSOV) in the fuel metering unit (FMU).

- The RDCs send the signals to the common data network (CDN) and then to the electronic engine control (EEC) to operate the FMU fuel valves (FMV and HPSOV).

The fuel control switches have 2 positions:

- RUN

- CUTOFF.

You must pull the switch out of a detent to select a position.

2) Looking at the incident timeline, one of the pilots takes corrective action to reswitch to RUN position 10 seconds after maximum air speed is reached and 5 seconds after RAT is deployed. Is this normal?

It's not clear however that whether their conversation is after or before the RAT is deployed.

(No visual or auditory cues in the cockpit for a critical fuel switch action? Not hearing the engines shutting down?)

3) The same pilot that turns on Engine 1's fuel switch, turns on Engine 2's switch 4 whole seconds later. Why not consecutively, right one after the other, just like they were turned off one second apart?

If only he had done so the second engine might have recovered in time as well.

4) This aircraft's TCM has been replaced in 2019 and 2023, not related to a fuel switch issue. And there had been no fuel switch defect reports since 2023. One begs to ask if there had been a fuel switch defect report back in 2023 and what was the nature of it?

Are TCM's replaced as a whole, including the switches, twice? If so, why wouldn't they install a TCM version at least in 2023 with redesigned switches (w/ enhanced locking mechanism) mentioned in the FAA SAIB? Have they installed old/used TCM's manufactured prior to 2018 SAIB?

Please note that the RH and LH GE engines of the aircraft were only installed in March 2025 and May 2025 respectively, but they were used and dating from 2013 and 2012. Is this normal for a 12 year old Boeing aircraft to change so many mission critical components?

Electronic parts somehow, but how durable are those GE engines?

Thanks,

C.A.

When reading any of the data when it comes out, pay some attention to the sampling rate of the data being provided, it is quite possible to make erroneous assumptions where that is not taken into consideration. The data buses used to get data from the aircraft system to the recorder, and the recorders themselves use sequential sentences, and varyious rates.

IMHO.

Subjects

FAA

Fuel (All)

Fuel Cutoff Switches

Fuel Cutoff Switches (detent)

High Pressure Shutoff Valve

RAT (All)

RAT (Deployment)

RUN/CUTOFF

Spar Valves

Special Airworthiness Information Bulletin

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 14, 2025, 01:33:00 GMT

permalink Post: 11921803

Thrust lever position post-accident - it takes very little force to move the thrust levers, a little more than one pound-force at the knob. I'd be very surprised if the post impact position was the same as pre-impact (and lever angle is recorded on the FDR, so the investigators know where they were). In short - the post-accident lever position is not meaningful.

Fuel condition switch position detents - if the Indian investigators had any reason to believe that a failed or inoperative detent was a contributing fact, the authorities would have ordered a fleet-wide inspection (especially since it literally takes only seconds to do the inspection - the paperwork would take many times longer than the actual inspection).

Engine restart (i.e. "Quick Windmill Relight"): Even if the igniters were firing, at high power they won't actually spark (the electrical resistance or the air at several hundred psi prevents a spark) - so they won't spark until you get down somewhere near idle if you're close to sea level. Once the engine has dropped below the min idle, it takes a long time for it accelerate back to even an idle condition. At takeoff power, the compressor components get very hot - do a power cut the air coming in the compressor gets heated by the residual heat in the compressor. This in turn limits how fast you can add fuel in the burner without excessively back pressuring the compressor and causing a compressor stall. So it actually takes longer for the engine to accel to idle that it would during a normal (cold engine) start. The 5 seconds to 95% accel requirement referenced earlier is from a stable 'high' idle (we typically call it 'approach idle' since it's automatically selected when landing flaps are selected). Approach idle is ~10% N2 higher than the in-flight minimum idle, so that takes several more seconds. Bottom line, after initiating the Quick Windmill Relight, you're not going to have usable thrust for at least 30 seconds - probably closer to 60 seconds.

For all the complaining about this preliminary report, it actually goes into more detail than is typical.

BTW, my money is still on the 'muscle memory/action slip' or whatever you want to call it. I can easily imagine a scenario along the line of 'why did you turn off the fuel' - 'I didn't - oh wait - oh

...

...

The last line, is not a zero possibility, but at present the whole wiring system for the fuel control switches would need to be evaluated for any potential common fault that may be intermittent before I would lean towards the cognitive slip type error. The poor old FO would have both hands on the yoke from V1, irrespective of the company's SOP and so would have been rather unpleasantly surprised by the loss of performance. I think the 10 seconds in this case is remarkably fast observation-orientation-decision-action sequence, and that one engine had already started to recover towards operation is a credit to the design of the engine.

Subjects

FDR

Fuel (All)

Fuel Cutoff Switches

Fuel Cutoff Switches (detent)

Preliminary Report

Quick Windmill Relight

Relight

V1

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 16, 2025, 06:25:00 GMT

permalink Post: 11923431

With the image of the aircraft from the SE corner of the airport, it is pretty clear that the aircraft was performing admirably in compliance with Part 25 Subpart B up until the time that the music stopped. The rotate rate in the earlier video from the NE camera is nominal, and the SE camera shows a height and position along the runway that would have been appropriate for the certified performance. The operation was nominal until it went pear shaped, and at that point, even ol' Chuck Yeager hisself would have had a bad day too.

Lots of stiff competition for "most implausible theory" going on but I think my favourite so far is "could've mistakenly moved fuel control switches to cutoff when going for gear up selection". Geezus. 🤦♂️ Plenty of others, including engineering related ones, around this level of plausibility too. The phrase recorded on the CVR by one of the pilots involving questioning why the fuel control switches were moved to cutoff needs to be taken very, very seriously.

Last edited by fdr; 16th July 2025 at 06:41 .

Subjects

CVR

Fuel (All)

Fuel Cutoff Switches

Preliminary Report

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 17, 2025, 04:29:00 GMT

permalink Post: 11924113

Subjects

Fuel (All)

Fuel Cutoff Switches

Pilot "Why did you cut off"

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

August 06, 2025, 16:02:00 GMT

permalink Post: 11934214

Our training assumes that we always act in the manner that we trained, and that is an optimistic view of life. A review of most serious incidents and accidents leaves an impression that we are all subject to error and action slips. It is also quite true that in more events, the human is the variable that is able to adapt due to the ability to apply heuristics and occasionally intuitive responses to a condition that is outside of their training. Those are the saves, and they tend to be overlooked in our rush for judgement and certainty, and to have some level of assurance that an event cannot occur to us. The defence against error is monitoring system performance, to confirm that when we turn off a say, fuel pumps on an A340-300 to balance fuel (needless action, but sometimes eyepleasing is assumed to be better than leaving stuff alone) and accidentally turn off the HYD pumps, leading to a wild ride, our deliberate actions and cross checking of our movement of any switch, lever, coffee cup etc., is followed by the correct response. All of that is fine, until we do not have time to correct an accidental movement of a system control. FCS are considered to be "irreversible" due to the time to correct an action, and the criticality of the response to the system change, and so we have great checklists and design to ensure that procedurally we check before actioning a switch. That kind of works for engine failure and fire checklists, it gives little comfort to the case of selecting the gear up instead of flaps up, etc., and here is my concern with our assumption of intent from evidence of action.

It may well be that the investigation provides irrefutable and overwhelming proof that the FCS were placed to cutoff. That is looking likely. That in itself does not give the reasoning as to why that occurred.

Collectively we have been flicking the wrong switches (A340 wild rides) and levers, (DC8 etc.,) with lousy outcomes, for quite some time, presumably that is why we take inordinate efforts to check/verify actioning of irreverible systems, and yet, we also misplace keys, put wallets into fridges, etc as we are human. It is one thing to be human, most (not all of us) are, but it is another to understand what the intent of the person involved was, and that means we are a long way from assuming malfeasance or deliberate aforethought.

I do a fair amount of flight testing, and that involves some odd activity, and I don't trust myself to not make slips or errors, to the extent that for one aircraft, I carry a tennis ball that fits neatly over the end of the emergency shutdown handle of the engines that I am not intending to shutdown and subsequetly relight. I don't expect that alone stops making an error, it is simply a procedural step and an opportunity to differentiate between systems that may be worthwhile. We have had similar guards on FCS in the past, due to congnitive lapses leading to red faces, the P3 fuel and ignition switches being an elegant example. The intent of a guard that takes deliberate action is to increase the time available to comprehend what is about to occur, just as putting a post-it note over the LEM jettison is not a bad idea for the late senator of Colorado to have done on Apollo 13.

Just because something happened, doesn't give the reason why, and without that, there can be no "mens rea". It is appropriate to work to understand the why, that is the whole intent of Annex 13.

Subjects

Action slip

Annex 13

CVR

Engine Failure (All)

Fuel (All)

Fuel Cutoff Switches

Relight

Switch Guards

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.