October 11, 2010, 18:48:00 GMT

permalink Post: 5988337

If the charter flight did not involve a supersonic flight, then of course it wouldn't have been a problem, you would just have loaded enough fuel into that vast collection of tanks to maintain a 'subsonic' CG.

So, second answer, which is what I think you're thinking of: the case of a short charter with a supersonic "loop" over the Bay of Biscay, as both BA and AF did quite a number of times, with less fuel.

This is where I start thinking... and I admit I may be wrong.

Take a normal transatlantic flight, with all the tanks full at take-off.

By the time you started the supersonic acceleration (so with still a lot of fuel forward, only the fuel used in take-off and subsonic climb no longer there) the 10-odd tons in tank 11 (the trim tank in the tail) were already enough to shift the CG backwards to what was needed when supersonic.

So, with a smaller fuel load, getting the CG backwards to the right position would already be easier, even without fully filling tank 11. And of course no problem returning to the 'subsonic' CG.... plenty of space in the already partly empty tanks..

So I think the answer to your question is "no".

CJ

Subjects

Air France

British Airways

C of G

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

October 11, 2010, 18:59:00 GMT

permalink Post: 5988352

... on shorter charter flights was there a mininium ammount of fuel that had to be loaded just to always have enough fuel for CofG movement...

Yes, 35,000 kgs, at take-off, for a short supersonic flight. This would allow sufficient fuel to be transferred rearwards in order to achieve a CG approaching 59%.

If the flight was to remain subsonic, the fuel figure dropped to 25,000 kgs, as the required CG for subsonic cruise was 55% not 59%.

Both these figures were at take-off, so the estimated taxy fuel had to be added to these figures in order to arrive at the minimum fuel figure required to be loaded.

...was it possible to be in a position where trip fuel, fuel to an alternate etc was less than the fuel required for CofG movement after take off?...

No, at least it should not have been!

However, a situation was sometimes reached in flight, generally only towards the end of the planned supercruise portion of a LHR-BGI sector, where, with the aircraft at M2.00 and FL600, it was no longer possible to maintain a CG of 59%, as the "ballast" fuel, which had been transferred aft into tank 11, was now required forward again as "fuel" fuel, to top up other tanks which had reached their minimum permitted levels.

In this case, once the forward transfer of fuel had begun, the CG would also be slowly moving FWD, and one would be compelled to commence the decel and descent earlier than desired, something EXWOK touched on here much earlier in this thread.

Best Regards

Bellerophon

Last edited by Bellerophon; 11th October 2010 at 22:17 .

Subjects

C of G

FL600

LHR-BGI Route

Super-cruise

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

October 12, 2010, 03:44:00 GMT

permalink Post: 5989160

No, at least it should not have been!

I believe I heard that fuel was transferred during landing to partially counter this effect.

So my question is: Would it have been possible to land the Concorde with near zero fuel?

And a supplementary (

) Would it change the handling characteristics, and did this affect fuel calculations at all?

) Would it change the handling characteristics, and did this affect fuel calculations at all?

Subjects

C of G

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

October 30, 2010, 12:46:00 GMT

permalink Post: 6027195

Requirements :

- Manual landing, at V REF , only

- Minimum of one autothrottle operative at start of approach

- Contingency power available

- Specific fuel distribution achieved

- Record in Maintenance Log

Not permitted with :

- Slippery runway

- Precipitation covered runway

- 3-engine ferry

- 2-engine approach and landing

- Reduced noise approach

- Fuelled with wide-cut fuel

- Secondary nozzle locked out

- Brake unit isolated

- Total loss of Electric Trim

- Total loss of Pitch Stab

- Total loss of Electrical Signalling

- Suspected tyre failure

Notes

3-engine landings were permitted. For all landings the landing gear would be lowered earlier than normal to ensure the brakes were stone cold to start with, maximum reverse thrust would be used on landing, and braking modulated so as to use (nearly) all of the full length of the runway. Landing performance figures at 130,000 kgs were in the performance manual for most runways. Any runway for which this procedure had not been pre-authorised required some rather tedious calculations, using the generalised basic data and graphs found in the performance manual.

If manual performance calculations were necessary, the F/E and I usually seemed to find that another problem that required our urgent and undivided attention had come up, and we would reluctantly be compelled to hand over all the manuals, charts and graphs for the F/O to perform the calculations!

If the aircraft had an AFT ZFW CG (perhaps loaded with a lot of heavy bags in the rear hold), and given the specific fuel distribution requirements for a fuel saving landing, it was possible that the landing weight might have to be reduced below 130,000 kgs, in order to achieve a landing CG of 53.5%.

After landing, record the actual landing weight in the Maintenance Log using code 2899XXOO, sign it, and then leg it swiftly, to avoid M2Dude and the boys, who somehow always managed to imply that you were responsible for anything that had gone wrong with their pride and joy since they last handed her over to you!

Reasons

The clue is in the name! A possible saving of roughly 5,200 gallons of fuel, nearly 19,000 kgs, which need not be jettisoned, thus reducing the time spent in the air before re-landing, fuel costs and pollution.

Best Regards

Bellerophon

Subjects

Auto-throttle

Braking

C of G

Fuel Saving Landing

Landing Gear

Manuals

Nozzles

Reverse Thrust

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

November 24, 2010, 21:47:00 GMT

permalink Post: 6082336

When still in the skies us as operations loadcontroler on a different station but able to browse through the CDG passenger lists often checked for "the famous pax" on board the Lady (what was the nick for her at AF as someone (ChristiaanJ?) mentioned at AF the Concorde was a "he"?) I learned that a Concorde flight needed more than one loadsheet for the flight due to the complex fuelling system and the extreme move of the CG. Don't know if this is gossip or there's a true part in it. Did you get, except from the standard MACs for ZFW, TOW and LAW also a TOC MAC (maybe?).

Just wanted to say thanks to you all for the great time reading this thread.

Trabbi

Subjects

Air France

C of G

CDG

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 08, 2010, 18:05:00 GMT

permalink Post: 6110672

howiehowie93

Tom355UK

).

).

Jeepers Tom that is one hell of a question. Assuming there was a market for such a venture (personally not sure right now) I think you are looking at BILLIONS of $, and for this reason alone I think you'd find that a multi-national/continental effort would be required. There is little doubt that technology is not the major barrier here, but economics and political will. (Nice thought though, I do agree).

As far as a powerplant goes, well the PW5000 is a really superb engine, although well down on the thrust requirement for an 'NG' SST. More likely I would have thought would be e development of the Olympus, there was/is still such an enormous amount of potential in this basic design. (But who knows, this is all pure speculation anyway).

And have no fears about posting here Tom, most of us are quite happy to answer away (We've said before that there is no such thing as a stupid question; you are most welcome here

).

).

DavvaP

I am honoured to say that I was lucky enough to be onboard G-BOAF for that flight from LHR-BZZ and as far as I could tell, the liners had no impact whatsoever. One amusing

part of the flight was when we deliberately allowed tank 3 to run dry and see just what the indicated fuel quantity was as #3 engine flamed out (we were subsonic at this point of course). The gauge slowly crept down (in order for the tank to to run dry, the tank 7 & 8 transfer pumps were switched off) and we all watched in eager anticipation/dread....... as the counters reached zero weeeeeee... the engine flamed out. I am being completely honest here, the engine wound down EXACTLY at

ZERO

indicated contents).

part of the flight was when we deliberately allowed tank 3 to run dry and see just what the indicated fuel quantity was as #3 engine flamed out (we were subsonic at this point of course). The gauge slowly crept down (in order for the tank to to run dry, the tank 7 & 8 transfer pumps were switched off) and we all watched in eager anticipation/dread....... as the counters reached zero weeeeeee... the engine flamed out. I am being completely honest here, the engine wound down EXACTLY at

ZERO

indicated contents).

Those 7 aircraft really did look magnificent I know, it was just sad as to the reason they were all lined up there.

Mr.Vortex

Best regards to all

Dude

Subjects

AICU (Air Intake Control Computer)

Afterburner/Re-heat

Air France

British Airways

C of G

Elevons

G-BOAF

Intakes

N1 (revolutions)

Nozzles

Olympus 593

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 18, 2010, 15:20:00 GMT

permalink Post: 6129540

Speedbird 2, cleared take-off 31L.

You call 3-2-1 Now , start your stopwatch, pre-set to countdown from 58 seconds, and slam the throttles fully forward till they hit the stops. Four RR Olympus engines start to spool up to full power and four reheats kick in, together producing 156,000 lbs of thrust, but at a total fuel flow of 27,000 US gallons per hour. A touch of left rudder initially to keep straight, as the #4 engine limiter is limiting the engine to 88% until 60 kts when it will release it to full power. The F/O calls Airspeed building, 100 kts, V 1 , and then, at 195 kts, Rotate . You smoothly rotate the aircraft, lift-off occurs at around 10\xb0 and 215 kts. You hear a call of V 2 but you keep rotating to 13.5\xb0 and then hold that attitude, letting the aircraft accelerate.

The F/O calls Positive Climb and you call for the Gear Up . On passing 20 feet radio height, and having checked the aircraft attitude, airspeed and rate of climb are all satisfactory, the F/O calls Turn and you slowly and smoothly roll on 25\xb0 left bank to commence the turn out over Jamaica bay. Some knowledgeable passengers will have requested window seats on the left side of the aircraft at check-in, and are now being rewarded with a very close look at the waters of Jamaica Bay going by very fast! As you accelerate through 240 kts, the F/O calls 240 and you pitch up to 19\xb0 to maintain 250 kts and keep the left turn going to pass East of CRI.

54 seconds from the start of the take off roll you hear the F/O counting down 3-2-1 Noise whereupon the F/E cancel the re-heats and simultaneously throttles back to noise abatement power, around 96% as you pitch the nose down to 12\xb0 to maintain 250 kts. It is less than a minute from start of roll and already 435 US gallons of fuel have been used.

Speedbird 2, contact departure, so long.

Turning through heading 235\xb0M, the F/E quickly re-applies full dry power as you pitch up to 17\xb0 to maintain 250 kts, but simultaneously reduce the left bank to 7.5\xb0, in order to increase both the radius of turn (to stay on the optimum noise abatement track) and the rate of climb (less bank, higher RoC).

On climbing through 2,500 ft you increase the bank angle back to 25\xb0 left bank and as you approach the 253\xb0 radial JFK, you hear 3-2-1 Noise from the F/O for the second time. The F/E actions the second noise-abatement power cut back, you pitch down to 12\xb0 and, if not in cloud, sneak a quick peek out of your left hand window, looking for the car park by the Marine Parkway bridge, as you would ideally like to pass right over the car park, if possible, as we tip-toe quietly across the Rockaway Beaches, in order to minimise the noise impact on the residents.

Keep the left turn going and intercept the 176\xb0 radial outbound from CRI, and at 5 miles DME from CRI, call for the F/E to slowly re-apply full climb power as you pitch up to maintain 250 kts. We are still in US territorial airspace, below 10,000 ft, and subject to statutory speed control.

Speedbird 2, present position direct to SHIPP, climb FL230, no speed control.

The F/O selects direct SHIPP in the INS and tells you that she has selected that information into your Flight Director. Having checked that the gear lever is at neutral, you call for the Nose Up , and then the Visor Up . Flight deck noise levels drop dramatically as the Visor locks up. Now more than 12 miles away from the coast, we are clear of US speed control requirements so lower the attitude to 9\xb0, accelerate to V MO , currently 400 kts, and ask for the After Take Off Checks.

Speedbird 2, present position direct to LINND, climb in the block FL550-600, accelerate Mach 2.0

Call for the Climb Checklist at Mach 0.7, which will trigger the F/E to start pumping fuel rearwards to move the CG aft, then when he's done that, straight into the Transonic Checklist . Maintain 400 kts IAS, and around 24,500 ft, at M0.93, ask for the re-heats back on, in pairs, and raise the nose by 3\xb0 to maintain 400 kts as they kick in.

Precise, smooth flying is required through the high drag transonic region, as the mach meter creeps up towards Mach 1. A sudden flicker on the VSI and Altimeter confirms that the shock wave has just passed over the static ports, and the aircraft is now supersonic. A quick glance at the elapsed time indicator shows that you\x92ve been hand flying for just over 9 minutes since the start of the take off roll.

Another fun start to a day in the office, and to think we got paid for doing it!

Best Regards

Bellerophon

Subjects

Afterburner/Re-heat

C of G

Checklists

Fuel Burn

Hand Flying

IAS (Indicated Air Speed)

INS (Inertial Navigation System)

JFK

Noise Abatement

Rolls Royce

Rudder

Static Ports

V1

V2

Visor

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 19, 2010, 18:24:00 GMT

permalink Post: 6131750

Sure the autopilot made it superfluous to some extent, but to certificate the aircraft it had to be conventionally stable when flow manually, and applying a nose down command to get a speed increase is a basic airworthiness requirement for all aircraft.

Subjects

Auto-pilot

C of G

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 19, 2010, 18:48:00 GMT

permalink Post: 6131785

After about half an hour we came to the conclusion that provided we put certain checks in place, and still retaining the 'classic' performance in the Flight Manual, we could insert a special TO technique using a single point CG which would give, from memory, about 1.5 tonnes more TO weight - something not to be sneezed at when your payload fraction is as low as Concorde. Needless to say this 'special' soon became the norm. I doubt if we could get agreement on such a topic in that timescale today!

I noted in another post that memory was blurring after seven years from active flying. I am writing about events thirty or even forty years ago, but I still have my notes.

Subjects

C of G

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 19, 2010, 19:13:00 GMT

permalink Post: 6131827

One of the major challenges was to match the fuel transfer rate and initiation point to the aircraft performance. Once started the fuel pumps change the rate of CG shift in a more or less constant manner, but the aircraft acceleration through the transonic range is very dependent on weight and OAT, so the actual CG at any one mach number will vary from flight to flight. But it must be possible to make an emergency deceleration form any point in the acceleration backdown to subsonic conditions where the aerodynamic centre will be further forward and hence there is a risk that the aircraft might get into unstable conditions.

A lot of work went into this problem and the allowable CG boundaries reflect thsi to some extent.

CliveL

Subjects

C of G

Fuel Pumps

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 21, 2010, 11:34:00 GMT

permalink Post: 6135285

So you need to know where the payload is going to be. Sud did flirt wit a 'bumsonseatometer' but eventually settled for allocated seating and simple preflight calculations (by the dispatcher I think, but ex-pilots would be able to help out on that)

Clive

Subjects

C of G

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 21, 2010, 12:09:00 GMT

permalink Post: 6135352

Sorry EXWOK, but I just don't agree that the aircraft was statically unstable in pitch at approach. When I think of the hours we put in trying to straighten that damned pitch curve!

It WAS designed to operate with low CG margins on approach, and that meant that the elevator (elevon) deflection needed to trim any desired incremental 'g' was quite small. On the other hand the pitch inertia was high and the elevon moment arm low, so if you just applied the elevon needed for the final state the pitch response would have been pathetic. This meant that the elevon needed to be 'overdriven' to get the aircraft moving and then backed off to hold it to the desired final state. Maybe the apparent reversals you are seeing in the video come from this source.

CliveL

Subjects

Auto-stabilisation

C of G

Elevons

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 21, 2010, 12:21:00 GMT

permalink Post: 6135362

Yup, I agree with that. I did the original control hinge moment calculations before we joined up with Sud, and the static hinge moments generated are quite impressive!

In fact the most critical zone is the transonic region and some (most) of the CG boundaries in the 'transonic corridor' are defined by hinge moment capability to provide the necessary manoeuvre 'g', especially with one system inoperative. The control rates aren't all that demanding, but the static hinge moment definitely was critical, and as you say, frontal area is everything and the jacks lie outside the wing section profile.

CliveL

Subjects

C of G

Shockwave

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 22, 2010, 21:43:00 GMT

permalink Post: 6138360

You've pretty much worked HLI out. No particular special requirements, it was normally associated with 54% CG departures, since that was the norm with high fuel loads.

Contacts were bridged which allowed some of the tanks to operate at a higher level before shut-off. Sounds simple, doesn't it? But it was a pain in the a***.

The tanks were first filled to normal level (this got tank 11 filled) then a metered amount was uplifted with the bridges in place to those tanks with HLI (M2dude will remind me which they were.....I'm guessing 5,6,7,8 and maybe 9&10?????). It could take ages.

It was invariably followed by a taxy with a Pre Take Off Burn Off to get the CG to its correct position, so you now had the problem that you had to burn enough fuel from tanks 1-4 to allow them to be topped up by tanks 5 & 7 to the extent that 5 & 7 could accept fuel from tank 11 to bring the CG fwd to 54%. Because they were so full it could take ages to get 5 & 7 to accept fuel and then any bump or turn would shut them off. So overall you've filled the tanks, presumably because you need the fuel, but because you've done this you have to burn loads of fuel taxying while you get the CG sorted out.

As you guess, it was mainly a LHR-BGI thing, or a JFK with weather problems, and more often than not you gained very little.

Subjects

C of G

JFK

LHR-BGI Route

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 26, 2010, 08:21:00 GMT

permalink Post: 6143472

Generally speaking the region from say 0.98 to 1.2M is one to pass through and be thankful!

CliveL

Subjects

C of G

FL600

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 26, 2010, 18:47:00 GMT

permalink Post: 6144161

One would expect a curve for constant alpha max against IAS and altitude, not the staircase in the diagram.

Was this for simplicity of use of the diagram?[quote]

I don't have a complete explanation for all the regions - it was a long time ago and I'll need to dig, but:

Below 16000 ft Vla obviously needs to go as low as Vref to cover landing at elevated airfield altitudes. At present I don't have a satisfactory explanation for 250 kts between 16000 ft and about 45000 ft (250kts/Mach 1.0) A constant value in IAS is what you would get for a constant CLmax (the alphamax is not really the driver). Vla should give a margin above stall, and a quick sum suggests that 250 kts would be consistent with a 1.3Vs condition and a CLmax of about 0.8 up to Mach 1.0, which is not unreasonable, but I am not saying that is the correct interpretation.

From 45000 ft to 60,000 ft I think Vla may be set by manoeuvre requirements. Certainly the forward CG envelope boundary between 1.0M and 1.5M discussed in earlier posts is very close to the requirement to be able to pull 1.2g with half hinge moment available at Vla and heavy weights. Again not certain, but best guess at the moment.

This is the 'simplest' one: it was the highest 'safe' altitude from which an emergency descent could be made, in the case of a window blowing out, without having the blood of the pax boil....

Test flights (without pax, and with the crew pressure-breathing oxygen) did go as high as 69,000ft.

[quote ]Mmo (max operating Mach number)

Mach 2.04 is usually quoted as having been chosen to assure an adequate life of the airframe.

But what effect does a higher Mach number as such have?

Or are Mmo and Tmo (127\xb0C) directly related?[quote]

I have always been puzzled by this statement as one does not normally associate Mach Number with a life limit. Going through my collection of lectures I found another, more plausible explanation:

quote" The scheduled cruise mach Number was 2.0. associated with a structural total temperature of 400 degK. Above ISA +5 Mc was cut back to maintain 400 degK.

To cope with variations of flight mach Number about Mc associated with often rapid and significant changes in wind and temperature which occur particularly in the vicinity of the tropopause (which can of course be as high as 60,000 ft in the tropics) a maximum operating Mach Number (Mmo) of 2.04 is selected" unquote [Leynaert, Collard and Brown, AGARD Flight Mechanics Symposium October 1983]

This is much more in line with my memory on this subject.

I suppose this is related to structural limits (qmax)?

What is the limiting factor here (other than qmax)?

What is the limiting factor here? The answer will no doubt also explain why this is slightly weight-dependent.

Why the sudden change below 5,000ft?

a) there is absolutely no advantage is having a high Vmo at low altitudes as it could not be exploited even if one wanted to because of ATC limitations to 250 kts below 10,000 ft (in the USA at least)

b) there are a lot of things that get rapidly worse if you encounter them at high speed and which are anyway more likely at low altitude - hail, birds etc.

So why store up trouble for yourself!

CliveL

Subjects

C of G

Depressurisation

IAS (Indicated Air Speed)

Mmo

TMO (Temprature Max Operating)

Vmo

Vref

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 14, 2011, 08:29:00 GMT

permalink Post: 6178845

The prototype had even more 'droop' in front of the intakes, but that produced a vortex at low incidence (near zero 'g') that went down the intakes and provoked surge.

Cheers

Clive

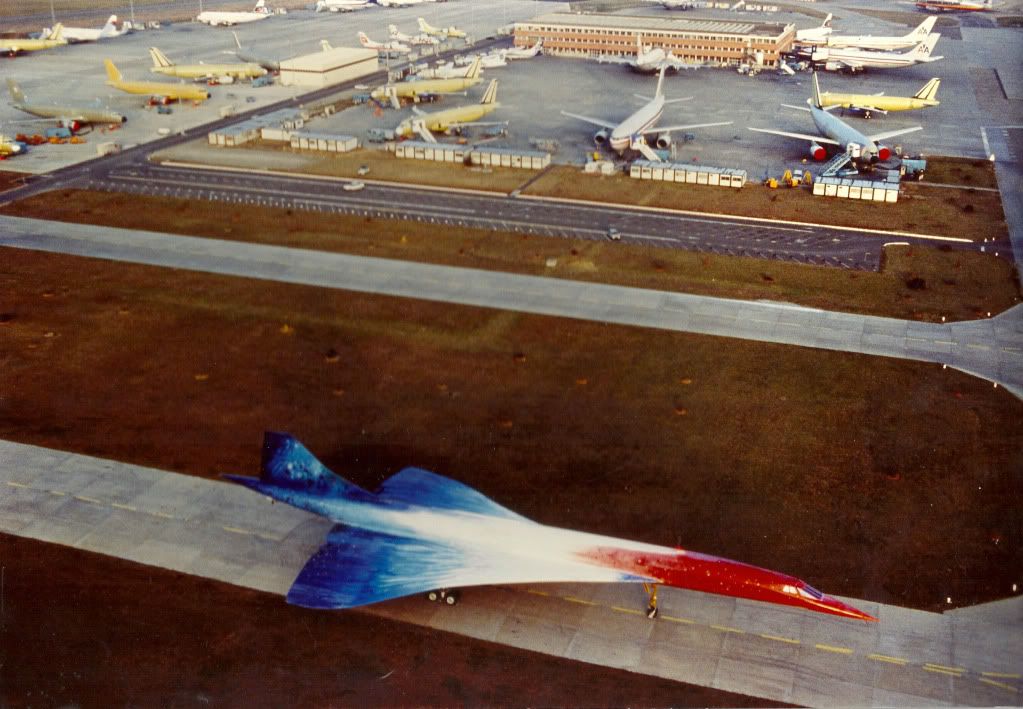

PS: Everyone seems to be adding their favourite Concorde photograph so I thought I would be different and add my LEAST favourite

">

">

Last edited by CliveL; 14th January 2011 at 08:43 . Reason: adding a photo and additional remarks

Subjects

C of G

Engine surge

Intakes

Trim

Vortex

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 18, 2011, 09:30:00 GMT

permalink Post: 6186581

Clive, you really surprise me when you say you don't think that composites would be used from a future SST, is there a material reason for this? (I'm curious because being of a simple avionic brain, I always assumed composites would be used. But if anyone knows this stuff, you certainly would Clive

).

).

To answer Mike-Bracknell's original query, as far as avionics goes we can really go to town. For her age Concorde had some truly amazing aircraft systems, for instance the flying controls. To enable mechanical control (both FBW channels failed) there was a highly complex and heavy mixing unit under the rear floor. (To mix pitch and roll pilot mechanical demands into differential elevon demand inputs). This of couse would have to be done away with, as well as the relay jacks and replaced with a pair of side-sticks. (See posts on previous page). A 2 crew operation would obviously be the way to go, but neither desirable or possible in my view when Concorde was designed.

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

Best regards

Dude

Subjects

ADC (Air Data Computer)

AICU (Air Intake Control Computer)

Afterburner/Re-heat

Avionics

C of G

Elevons

FBW (Fly By Wire)

Intakes

Nozzles

Thrust Reversers

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

April 12, 2011, 05:47:00 GMT

permalink Post: 6364687

On the planned test profile, we entered a programmed 35-deg. bank turn to the right. An immediate unstart occurred on the right engine, forcing the aircraft to roll further right and start to pitch up. I jammed the control stick as far left and forward as it would go.

No response. I instantly knew we were in for a wild ride.

The cumulative effects of system malfunctions, reduced longitudinal stability, increased angle-of-attack in the turn, supersonic speed, high altitude and other factors imposed forces on the airframe that exceeded flight control authority and the Stability Augmentation System's ability to restore control.

The next day, our flight profile was duplicated on the SR-71 flight simulator at Beale AFB, Calif. The outcome was identical. Steps were immediately taken to prevent a recurrence of our accident. Testing at a CG aft of normal limits was discontinued, and trim-drag issues were subsequently resolved via aerodynamic means. The inlet control system was continuously improved and, with subsequent development of the Digital Automatic Flight and Inlet Control System, inlet unstarts became rare.

Subjects

Air France 4590

C of G

Intakes

SR-71

Simulator

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

June 21, 2011, 15:45:00 GMT

permalink Post: 6527294

I'd still personally like to know how the sidestick was integrated into the flying control system, I've been thinking and can not now believe that sidestick inputs could be simply input to the flying control system 'at resolver level'. Remember that the concept of the FBW system on Concorde was that resolvers were utilised as simple 4 wire synchros, and the pitch and roll axis utilised a CX/CDX/CT chain, which produced the error signal to the ESA's in the Autostab computers. Using a sidestick completely breaks up the chain, and my guess is that a seperate digital unit contained the flight rules which were summed against PFCU CT position and sidestick input would have been necessary. It is possible then that an analog output from this 'box' could be fed to the Autostab Computer ESAs and hence drive the elevons. I'm probably completely wrong, but I'd surely still love to know the truth. As you say Clive, ideal stuff for Concorde 2.

Best regards

Dude

Last edited by M2dude; 21st June 2011 at 18:53 . Reason: A fine wine may improve with age... my spelling however doesn't

Subjects

Auto-stabilisation

C of G

Elevons

FBW (Fly By Wire)

PFCU (Powered Flying Control Units)

Sidestick

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.