December 21, 2010, 11:54:00 GMT

permalink Post: 6135331

A lot depends on how fast you were flying. You can get pretty good values of Lift/Drag ratio (that defines the potential glide slope with all engines operating, if that is not a contradiction in terms) from the Concorde B pages of the Concorde SST site. The actual glide slope with engines out would have been a lot worse than those numbers because of windmilling and (supersonically) intake spillage drag.

Nowhere near any subsonic values!

Clive

Subjects

Glide

Intakes

Lift Drag Ratio

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 21, 2010, 13:04:00 GMT

permalink Post: 6135427

Just for the record, the intake control system was designed to cope with a temperature shear of 21 deg C in one mile (about 3 seconds)

quote:Not meaning to go off onto a (yet another) tangent; Negative temperature shears, very common at lower lattidudes, always plagued the development aircraft; you would suddenly accelerate, and in the case of a severe shear, would accelerate and accelerate!! (Your Mach number, quite naturaly, suddenly increased with the falling temperature of course, but because of the powerplant suddenly hitting an area of hyper-efficiencey, the A/C would physically accelerate rapidly, way beyond Mmo). Many modifications were tried to mitigate the effects of severe shears, in the end a clever change to the intake control unit software fixed it. (Thanks to this change the production series A/C would not be capable of level flight Mach numbers of any more than Mach 2.13, remembering that Mmo was set at 2.04).unquote

Not temperature shears, and not AICU modifications (which I see has been discussed in a later posting). But back to the 'shears':

Most of Concorde's flight testing was, naturally, done out of Toulouse and Fairford, i.e. into moderate latitude atmospheres where the tropopause is normally around 36,000 ft so that the supersonic flight testing was done in atmosphers where the temperature doesn't vary with altitude. The autopilot working in Mach hold would see an increase in Mach and apply up elevator to reduce IAS and recover the macg setting. But at the lower latitudes around the equator the atmosphere is different in its large scale characteristics. In particular the tropopause is much, much higher and can get as high as 55,000 ft. Nobody had been up there to see what it was like! Now when the A/P applied up elevator to reduce IAS it went into a region of colder air. But the speed of sound is proportional to air temperature, so as the aircraft ascended the IAS dropped alright but since the ballistic (true) velocity of the aircraft takes a while to change and since the speed of sound had dropped the Mach number was increased, so the A/P seeing this applied more up elevator and the aircraft went up and the speed of sound dropped and ........

Like solving crossword clues, the answer is obvious once you have spent some time finding it!

This phenomenon rather than temperature shears (encountered mainly over the tops of Cb clouds) was the reason for the autopilot modifications which included that clever use of autothrottle (I can use that adjective since it was my French colleagues that devised it)

And before anyone asks; yes, the same problem would relate to subsonic aircraft operating in Mach hold driven by the elevators and flying below the tropopause, but:

a) Subsonic aircraft are old ladies by comparison with Concorde in that they fly at only half the speed. At Concorde velocities even modest changes in pitch attitude can generate some pretty impressive rates of climb or dive!

b) Subsonic aircraft are normally constrained by ATC to fly at fixed flight levels - the use of elevator to control Mach number is not really an option - you have to use an autothrottle.

There was that other problem, also described in later postings, where the aircraft regularly 'rang the bell' when passing through the Vmo/Mmo corner in the lower latitudes, but this was simply due to the additional performance one got in these ISA minus conditions in comparison to the temperatures encountered around the same corner in higher temperatures.

Anyway, the flight test campaign got me my first sight of sunrise over the Arabian desert and my first trip to Asia, so it goes into my Concorde memory bank.

Subjects

AFCS (Automtic Flight Control System)

AICU (Air Intake Control Computer)

Auto-pilot

Auto-throttle

Fairford

IAS (Indicated Air Speed)

Intakes

Mmo

Temperature Shear

Toulouse

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 21, 2010, 16:53:00 GMT

permalink Post: 6135786

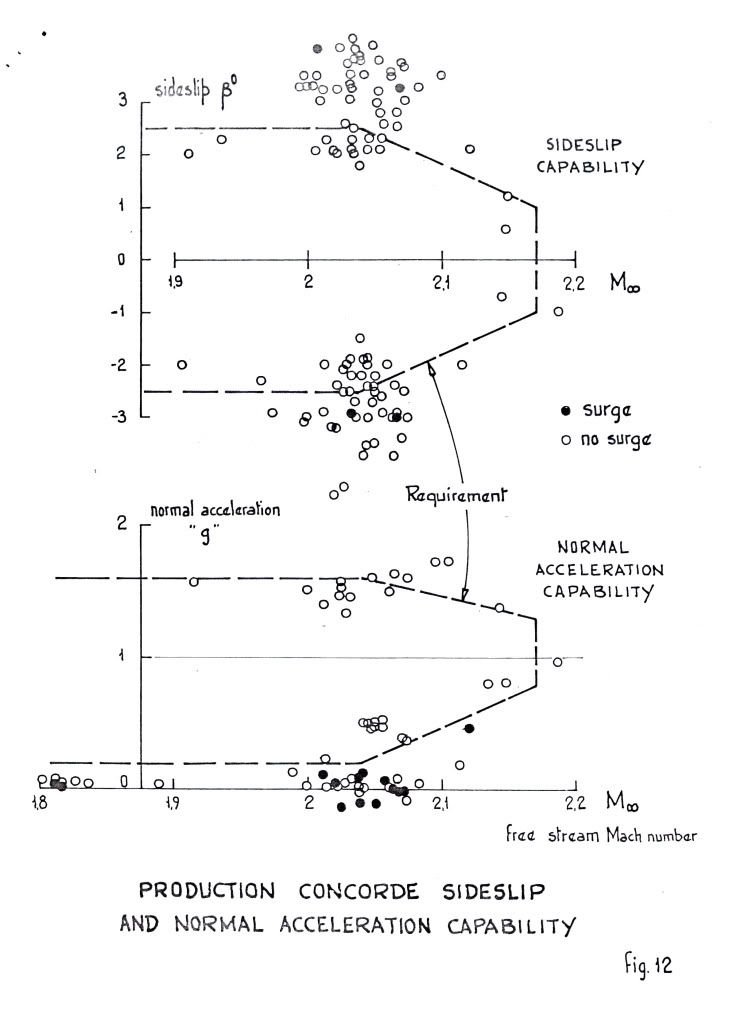

To rub it in, a typical double engine surge - they were nearly always double surges as the first surge expelled the ramp shock waves and turned the flow into a pitot with a large standing shock ahead of the intake that screwed up the flow into its neighbour - would produce about 1 degree sideslip and 2 deg bank. There would be a +/- 0.2g variation in normal acceleration and that was it! Through Christiaan's kind offices I am posting the records of such an event.

Hustler pilots eat your heart out!

CliveL

Subjects

Engine Failure

Engine Shutdown

Engine surge

Intakes

Sideslip

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 22, 2010, 20:40:00 GMT

permalink Post: 6138255

Closed loop

As an example, let's look (very simplified) at how the autopilot maintains a selected altitude.

On the one hand we have the desired altitude as selected on the autopilot controller (here 40,000 ft).

On the other hand we have the true altitude , as measured by the altimeter (let's say 39,000 ft).

We subtract the two to obtain the altitude error (in this case 39,000-40,000=-1,000 ft).

We 'multiply' the altitude error by a factor, the gain (for the discussion, let's assume this gain is 1 degree elevon per 1000 ft altitude error), and send the resulting elevon position command to the elevon.

So, the elevon moves 1\xb0 nose-up, the aircraft starts to climb, the altitude increases and the altitude error decreases until it becomes zero, by which time the elevon position has also returned to zero.

What we have now is a "closed loop" : any deviation from the selected altitude results in an elevon command in the opposite direction, until the deviation is again reduced to zero.

Another commonly used term is "feedback" : any error is fed back in the opposite sense until it's reduced to zero.

The significant figure here is the 'gain'.

If the gain is too small, the autopilot response to a disturbance (say turbulence) will be sluggish ; the aircraft takes too long to return to the desired altitude.

If the gain is too high, a small disturbance will cause the aircraft to start climbing too rapidly, and to overshoot the desired altitude, then descend to correct the new error, etc.

In other terms, the control loop is no longer stable, but starts to oscillate.

Both theory and practice show that the exact value of the gain is not all that critical, a few percent more or less do not markedly change the response of the loop.

Note: a "closed control loop" as described above can be implemented in just about any way you like.

It can be done purely mechanically, with a few clever clockwork mechanisms 'computing' the altitude error and controlling the elevator pneumatically or hydraulically. It's how the earliest autopilots worked.

After that came electromechanical systems, analogue computers and then digital computers... but the principle has remained unchanged.

Open loop

As already described in earlier posts, the situation with the automatic trim is the opposite.

We now need to compute a neutral elevon position from several data, such as Mach number or airspeed, but without any feedback as to whether our computations are correct.

We're now working in "open loop".

To complicate matters... that neutral elevon position is not a simple linear function of Mach and airspeed, but far more complex (see the earlier posted graphs).

And because of the large response of the aircraft to small changes in trim, in particular in the transonic regions, those computations have to be far more accurate : a one degree error is simply not acceptable.

In the end.....

The AICS (air intake control system) also uses several "open loop" functions.

The early development aircraft still had an analogue system, which proved all too soon to be inadequate, so, at a very late stage, it was replaced by a digital system (one of the rare digital systems on Concorde).

The "open loop" functions of the autotrim system initially had the typical "a few" percent" accuracy of the other flight control systems, which, for the autotrim, also proved inadequate.

We managed to "save the furniture" (as they say in French) by using 0.1% components in all the critical computing paths, so the autotrim computers remained analogue until the end.

But, a slide rule is not accurate to 0.1%... So that's when I had to buy my very first pocket calculator.

\xa342 at 1972 prices... just as well the firm paid.

CJ

Subjects

AICS (Air Intake Control System)

Auto-pilot

Auto-trim

Elevons

Intakes

Trim

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 23, 2010, 08:54:00 GMT

permalink Post: 6139001

Yes, of course (as ever

Yes, of course (as ever

) you are correct; it was technically a hybrid system: The servo loops, in terms of ramp and spill door demand signals and resolver position feedback signals etc. DID use conventional analogue drive and servo amplifiers within the AICU, it was the massive arithmetic computation UP-STREAM of these that was digital. I always used to like to refer to the AICS as 'an analog front end with a digital brain'. But that's just me

) you are correct; it was technically a hybrid system: The servo loops, in terms of ramp and spill door demand signals and resolver position feedback signals etc. DID use conventional analogue drive and servo amplifiers within the AICU, it was the massive arithmetic computation UP-STREAM of these that was digital. I always used to like to refer to the AICS as 'an analog front end with a digital brain'. But that's just me

.

.

But as you say Clive, none of the control law sophistication (including the synthesising the intake face total pressure and local Mach numbers from mainline aircraft raw air data) would have been possible using analog computation.

Best regards

Dude

Subjects

AICS (Air Intake Control System)

AICU (Air Intake Control Computer)

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 24, 2010, 13:02:00 GMT

permalink Post: 6141291

Christian asked if there was an aerodynamicist in the house - I guess that would be me!

Christian asked if there was an aerodynamicist in the house - I guess that would be me!

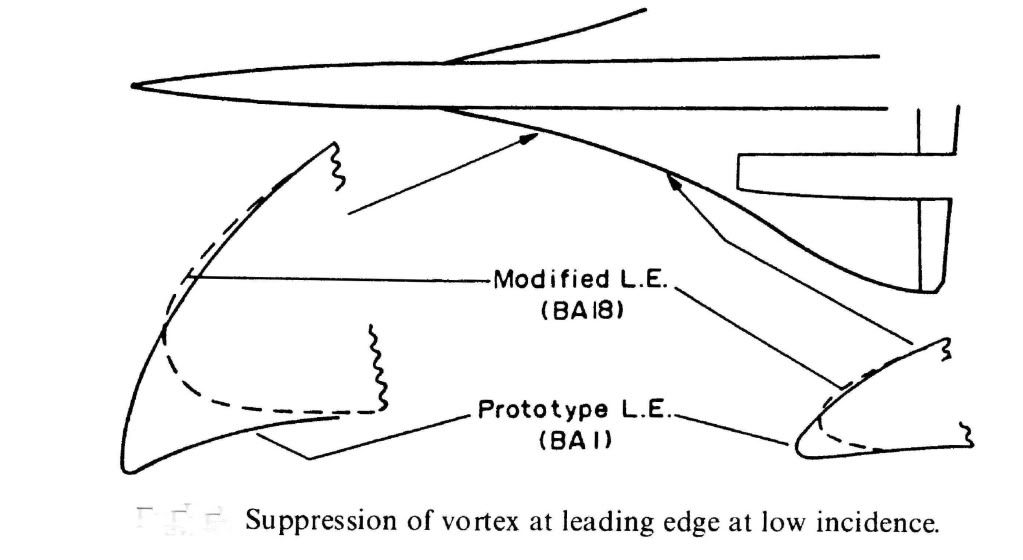

The original question was whether there was any vortex activity in subsonic cruise, but the discussion went on to ask about designing for subsonic drag I think.

The answer to the first bit is that the vortex flow started in a gentle manner from about 6 or 7 deg AoA and got steadily stronger. Depending on the chosen cruise speed and the aircraft weight, the subsonic cruise AoA would have been in the region of 4.5 to 5 degrees, i.e. below any significant vortex development. 6/7 deg would correspond to something in the range 250 to 280 kts probably (I haven't done the sums)

What we were trying to do for subsonic cruise was to have what is known in the trade as 'leading edge suction' acting on a nice bit of forward facing area so that it tried to drag the aircraft forwards as it were. As you can see from the diagram the prototype aircraft had a much more cambered LE so that both suction and forward facing area were very reasonable. This prototype shape was nicely rounded so that LE separation and top surface vortex generation started at a higher AoA than on the production aircraft. Unfortunately this shape, which featured a rather sharp LE on the undersurface, generated a vortex on the undersurface of the wing in supersonic flight and low AoA (near zero 'g'). This vortex got into the intake and caused the engine to surge, so we had to redesign the LE ahead of the intakes as shown. This cost us a little subsonic drag, so you can see from the diagram what you need to do to keep subsonic cruise drag down.

Hope this answers the questions

CliveL

Subjects

AoA

Engine surge

Intakes

Vortex

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 24, 2010, 21:35:00 GMT

permalink Post: 6142030

In my case, it's easier... I've become bitten by the Concorde bug again over the last ten years or so, and pulled dozens of similar diagrams from the documentation to refresh my memory.

Op-amps also were used for other functions such as demodulators (converting AC signals to DC) or comparators and level detectors.

I still mean to write some posts on "how to compute without a digital computer", but it'll have to wait until after the holidays.

In the 'olden' days we'd draw block diagrams like the one for the SFC, and once we agreed about all the functions we wanted, we just drew the schematics for each of the functions.

No sequencing, no real-time clock, no A/D or D/A conversion, no worries about cycle time or memory allocation. No programming-language issues, no naming of variables, no compiler faults, no software to debug.

You should try it sometime......

The major issue was, of course, that you ended up with a lot more hardware for the same functionalities, hence more weight, and more power consumption.

And the other issue, already alluded to in earlier posts, is that analogue computing is inherently not highly accurate.

In many cases of system control, a percent or two of precision is perfectly acceptable. But if a far higher precision is needed, like for instance in the intertial navigation system, or the core computing for the air intakes, only digital computing can do the job.

Seasons greetings to everyone on this thread from me too.

Christian

Subjects

Fuel Burn

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

December 27, 2010, 14:04:00 GMT

permalink Post: 6145144

This actually is interesting in that the n umbers show one of the fundamental features that made the Ol 593 such a good choice. If you look closely at the TO and cruise values you will find that at TO the overall compressor pressure ratio is 13.5 the compressor exit temperature 460 degC and the turbine inlet temperaure is 1152 degC. In cruise the pressure ratio is 10.5, the compressor exit is 565 degC and the TET 1100 degC.

Somebody, I can't find the exact post, was asking whether the elevated cruise total temperatures affected engine life, and here we see why this is so. As Christian said in another posting, when you compress air it gets hotter - from 21 degC to 460 degC at take off and from 127 degC to 565 degC in cruise. A fundamental limit on engine operation is the turbine entry temperature. Not only does it affect the maximum TO thrust you can get but also the continued exposure to cruise TETs has a very big effect on engine fatigue life, and engine manufacturers have shown extremes of ingenuity when developing new materials and ways of cooling the blades to increase allowable TET.

The problem with supersonic operations is that you start from an elevated intake delivery temperature so that when the flow exits the compressor it is already very hot 565 instead of 460 to be exact. But the maximum temperature one can stand for fatigue reasons is limited, therefore the amount of fuel you can pour in must be limited also, and the thrust you can develop per pound of airflow is roughly proportional to the fuel input/temperature rise. To get any sensible cruise thrust then one must squeeze the cruise TET as high as you dare for fatigue reasons but also you need to keep the compression ratio down so that the temperature going into the combustion chambers is as low as you can get away with. This tend to drive engines designed for extended supersonic operations to having a low pressure ratio. This is against the trend in subsonic operations where compression ratios have been steadily increasing along with bypass ratios.

The net result then is that the engine must be designed with a low OPR and must operate with cruise TET much closer to its TO TET value than would be necessary, or indeed desirable, on a subsonic design.

I was not even aware of this A33/340 similarity, sounds yet another case of Airbus using Concorde technology. (Immitation still is the greatest form of flattery I guess). As far as I am aware Concorde had none of the lubrication issues that you describe. M2Dude

Actually, here, as on some other apparent carry-overs, one should look at the equipment supplier rather than the aircraft manufacturer to trace continuity. Here we have Messier supplying Concorde's gear and Dowty (OK they are now part of Messier) supplying the A330. And having worked on both, I seem to remember that the means of doing the shortening are quite different.

Yes, they both came out of the Bristol drawing office. One minor anecdote: the 'ramshorn' stick was a novelty to the Concorde flight test crews but they got to like it, or at least put up with it. All went well until it came to the time when Dave Davies, the ARB Chief Test Pilot, came to put his rubber stamp on the aircraft.

Concorde's seats, just like those on your car, could be moved back and fore to get your legs on the pedals and up and down so you could see over the bonnet (sorry, instrument panel). The control column of course stayed in one place, so the relationship of the 'horns' to ones thighs varied with ones height. Andre Turcat was about 6ft 2in, Trubbie and the others of average height. The smallest regular pilot was Jean Franchi at, I suppose, about 5ft 7 or 5ft 8. No problems. But Dave Davies was short like me and he found that he could not get full back stick and full aileron because the ramshorn fouled his thighs.

Consternation! Completely unacceptable! I don't know what arguments they used to convince him it was all OK really, but it got through certification. I would certainly be interested to learn from the pilots in this group as to whether it was ever a problem.

I can't resist this one!. Has anyone ever noticed/wondered about the tiny bit of the outer elevon that has been chopped off? That was my first real input into the design as a young erk looking at variability of touchdown conditions and coming to the conclusion that if the pilot got into trouble and was trying to pick up a trailing wing with too much AoA as well then he was likely to hit the ground with the downgoing elevon. I persuaded my boss that this was so and we made a small adjustment.

In self defence I am going to plead that this was well before the days of the Type 28 nozzle, so the issue of buckets contacting the ground first never came up!

To the point where an American Airline maintainance engineer, watching a prototype taking off and with full benefit of being located strategically for maximum sideline noise, remarked on what he described as 'visible acoustic radiation'

On another occasion, it was reputed that Stanley Hooker, watching a TO in the company of HRH the Duke of Edinburgh, remarked that "You know Sir that that noise represents less energy than it takes to boil an egg". to which he got the reply "Then I must congratulate you Sir Stanley, on producing so much noise for the expenditure of so little energy".

There was an effect and in consequence the aircraft performance brochures were formally calculated for north/south flight. Pity really, it would sometimes have been nice to be able to fly guarantee performance demonstrations in the most favourable direction

That's enough for today!

CliveL

Subjects

Afterburner/Re-heat

Airbus

Andre Turcat

AoA

Boeing 747

D. P. Davies

Elevons

Fatigue

Intakes

Nozzles

Olympus 593

Radiation Exposure

Rolls Royce

Sir Stanley Hooker

Thrust Reversers

Visor

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 02, 2011, 16:17:00 GMT

permalink Post: 6155241

And of course a happy 2011 to all!

CliveL

Last edited by CliveL; 2nd January 2011 at 16:25 . Reason: Additional information

Subjects

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 04, 2011, 11:58:00 GMT

permalink Post: 6158425

.

.

CliveL

Poornamechoice

(But I am so glad that you are enjoying this wonderful thread).

(But I am so glad that you are enjoying this wonderful thread).

ChristiaanJ

Speaking for myself, no, it's not a void, it's a highlight, that I now like passing on, in the hope other generations will find inspiration in the 'Concorde Story' for their own endeavours.

).

).

What is gratifying though, is the enormous amount of interest that there still is for Concorde; both in this thread and in the world at large. I guess she lives on after all.

These pictures of 101 etc are absolutely marvellous; I really like the 'sexy' wing shape photo's. One little unique point about 102; she flew with a different intake control system to any other Concorde, being an 'improved' Ultra Electronics analog system. (Although the intake itself was aerodynamically the same as the later aircraft). Never really understood why our French friends chose this particular path with this aircraft. (Perhaps CliveL can shed some light on this??).

Very best regards to all.

Dude

Last edited by M2dude; 5th January 2011 at 16:54 . Reason: Still can't spell

Subjects

British Airways

Intakes

Nozzles

Thrust Reversers

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 06, 2011, 19:02:00 GMT

permalink Post: 6163302

One little unique point about 102; she flew with a different intake control system to any other Concorde, being an 'improved' Ultra Electronics analog system. (Although the intake itself was aerodynamically the same as the later aircraft). Never really understood why our French friends chose this particular path with this aircraft. (Perhaps CliveL can shed some light on this??)

One of the things I like about this thread is the way in which it reminds me of things I had forgotten about the design phase - or in this case informs me of things I maybe never knew! I just do not remember any improved Ultra AICU design. So far as the French 'choice' on the matter, they probably weren't given one. Like the rear fuselage alterations referred to in another posting , it was all a matter of timing. 102 came after 101 so 102 got the lengthened rear fuselage (which was done to improve the 'area rule' distribution and gave about 2.5% drag reduction). We (BAC) were going to do the AICU development so it made sense for 101 to get the early hybrid units. [If you were cynical you might equally say that there was no way we were going to let AS have them first!].

CliveL

Subjects

AICU (Air Intake Control Computer)

Area Rule

Filton

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 06, 2011, 21:06:00 GMT

permalink Post: 6163491

"We (BAC) were going to do the AICU development so it made sense for 101 to get the early hybrid units. [If you were cynical you might equally say that there was no way we were going to let AS have them first!]."

Is that a typo and did you mean "it made sense for 102 to get the early hybrid units."?

I think M2dude had more fun with the air intakes at the time than I had with the AFCS, although getting MAX CLIMB and MAX CRUISE to work was, to say the least, "interesting".

Christian

Subjects

AFCS (Automtic Flight Control System)

AICU (Air Intake Control Computer)

Climb Performance

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 07, 2011, 13:13:00 GMT

permalink Post: 6164710

Gentlemen, I think you will find that 102 did indeed have a totally 'unique' analog intake control system. Not only were the RDCUs (not AICUs in this case chaps) totally different, there were major architectural changes over the prototype system too. Also, although the basic intake structure was the same as 101 and all subsequent aircraft, there was still the prototype approach to local pressure sensing adapted, ie. Intake face total pressure P∞ sensed directly via the infamous 'magic holes' rather than using digitally synthesised values based on mainline aircraft manometric probe, total (pitot)pressure. As 101's intakes only went 'live' in mid-march 1973, I assumed that maybe they (AS) wanted an operative intake system from the outset on 102 when it first flew in January of that year. What puzzled me was why they went for this seemingly enhanced (and expensive) analog system on 102 and not the original system. (As 102 used a production type intake, I guess that they would have to have at least made some changes to the control system ; there was no exotic double hinged 'Dump Door', but the far simpler and elegant 'Spill Door' with integral Aux' Inlet Vane that was known and loved by us all). Rumour had it that AS still wanted to pursue the 'magic holes' solution and were dead against the decision to go digital. (This particular decision was taken in October 1970, which makes the 102 AICS route seem all the more strange).

And ChristiaanJ; what you guys achieved with the MAX CLIMB/MAX CRUISE was nothing short of remarkable. Just about the most exotic (and complex) autopilot mode that I've ever seen, that solved so MANY problems.

(Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

(Still the only A/P mode I've ever seen where the Autothrottle is engaged in a speed mode at the same time as the AUTOPILOT

).

).

Best regards

Dude

Last edited by M2dude; 8th January 2011 at 09:58 . Reason: 'All I want for Christmas is the ability to spell'

Subjects

AICS (Air Intake Control System)

AICU (Air Intake Control Computer)

Auto-pilot

Auto-throttle

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 13, 2011, 09:45:00 GMT

permalink Post: 6176684

Really an answer for CliveL, but I'll have a go. The short answer to your question is 'oh yeah, big time'. Total temperature varies with the SQUARE of Mach number and static temperature. Depending on the height of the tropopause itself as well as other local factors, there can be little or no significant variation of static temperature between FL600 and FL700. The 400\xb0K (127\xb0C) Tmo limit was imposed for reasons of thermal fatigue life, and equates to Mach 2.0 at ISA +5. (Most of the time the lower than ISA +5 static air temperatures kept us well away from Tmo). In a nutshell, flying higher in the stratosphere gains you very little as far as temperature goes. (Even taking into account the very small positive lapse above FL 650 in a standard atmosphere). As far as the MAX SPEED bit goes, Concorde was as we know flown to a maximum of Mach 2.23 on A/C 101, but with the production intake and 'final' AICU N1 limiter law, the maximum achievable Mach number in level flight is about Mach 2.13. (Also theoretically, somewhere between Mach 2.2 and 2.3, the front few intake shocks would be 'pushed' back beyond the lower lip, the resulting flow distortion causing multiple severe and surges).

On C of A renewal test flights (what I always called the 'fun flights') we DID used to do a 'flat' acceleration to Mach 2.1 quite regularly, as part of the test regime, and the aircraft used to take things in her stride beautifully. (And the intakes themselves were totally un-phased by the zero G pushover that we did at FL630). This to me was an absolute TESTAMENT to the designers achievement with this totally astounding aeroplane , and always made me feel quite in awe of chaps such as CliveL.

Shaggy Sheep Driver

So glad you are enjoying the thread, and absolutely loved the description of your flight in OAD and your photo is superb. I don't think it is possible to name a single other arcraft in the world that could be happily flown hands off like this, in a turn with 20\xb0 of bank at Mach 2. (One for you ChristiaanJ; The more observant will notice that we are in MAX CLIMB/MAX CRUISE with the autothrottle cutting in in MACH HOLD. Oh, we are in HDG HOLD too

).

).

Now for your question

As far as your air conditioning question goes, you needed an external air conditioning truck to supply cabin air on the ground. Not needed in the hangars of course, but come departure time if these trucks were not working, then the cabin could become very warm/hot place indeed (depending on the time of year). Oh for an APU

Best regards

Dude

Subjects

AICU (Air Intake Control Computer)

APU (Auxiliary Power Unit)

Anti-skid

Auto-throttle

Braking

Depressurisation

Engine surge

FL600

Fatigue

Intakes

Landing Gear

N1 (revolutions)

TMO (Temprature Max Operating)

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 13, 2011, 11:10:00 GMT

permalink Post: 6176851

On C of A renewal test flights (what I always called the 'fun flights') we DID used to do a 'flat' acceleration to Mach 2.1 quite regularly, as part of the test regime, and the aircraft used to take things in her stride beautifully. (And the intakes themselves were totally un-phased by the zero G pushover that we did at FL630)

As usual Dude you beat me to it! I really must give up having another life

As Dude says, the 'cruise' condition was set by the aircraft specification for transatlantic range on an 85% (ISA +5) day and the chosen mach Number was 2.0 (of which more anon). This gives a Total Temperature of 400.1 deg K. [Dude, I know your pipe-smoking thermodynamicist and he was having you on - he is quite capable of memorising the square/square root of 407.6 or whatever!]

To give margins for sudden changes in ambient temperature (we had to cater for a 21 deg change in one mile) the Mmo was set at 2.04 which matches 400 degK at ISA +1. In theory then we could have flown faster than our chose Mmo at anything colder than this, but there are two limits:

1) The object is not to fly as fast as you can but to fly with minimum miles/gallon. If you have a nice cold day and enough thrust to go either faster or higher which do you choose? For best specific range you go higher every time.

2) The thing that everyone forgets is that civil aircraft have to have margins around their authorised envelope. In Concorde's case these were set principally by the intake limits and engine surge.

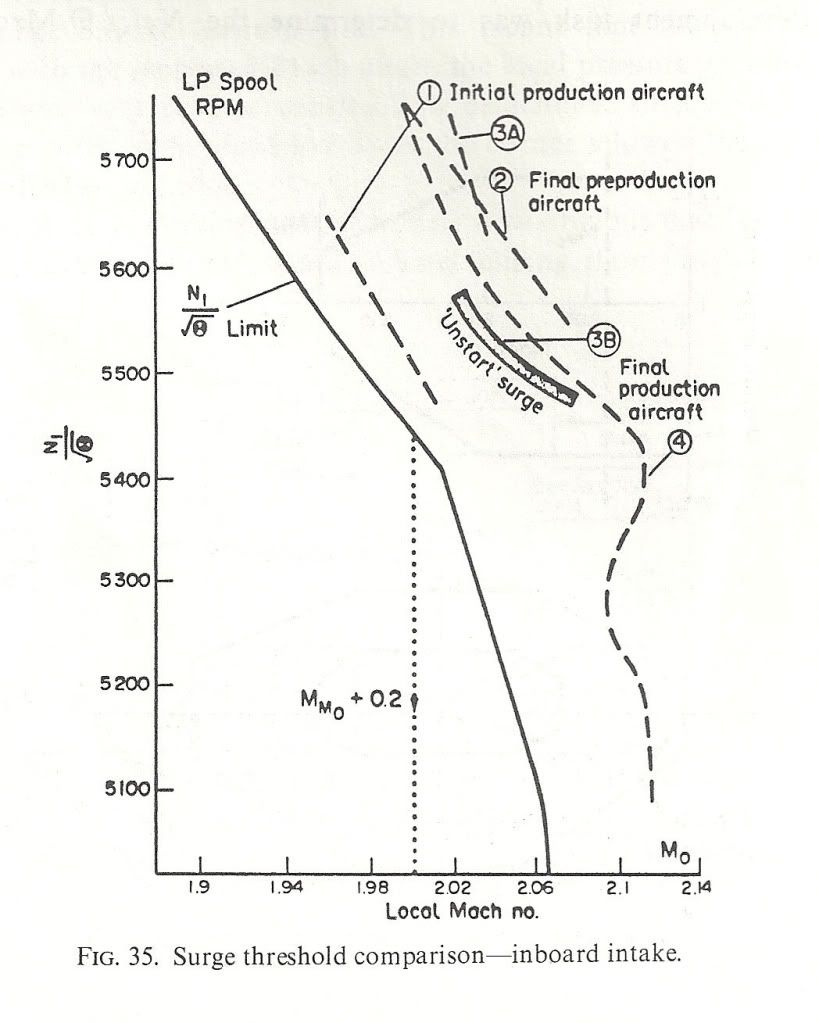

Dude also says quite correctly that 101 flew to 2.23M but the production aircraft was limited to 2.13M. Now you may not believe this, but 101 could fly faster than the production aircraft because she (101) leaked like a sieve!.

I doubt I will get away with that without some explanation

Once you get past a certain Mach Number the airflow into the intake is fixed. The performance (intake pressure recovery and engine face flow distortion) then depends on how this air is shared between the engine and the throat 'bleed'. This bleed was ducted over the engine as cooling air and then exhausted (in principle) throught the annulus formed between the expanding primary jet and the fixed walls of the con-di nozzle. But if you took, or tried to take, more bleed air the intake pressure recovery went up and the primary jet pipe pressure went up with it. This meant that the primary jet expanded more and squeezed the available annulus area which restricted the amount of bleed air one could take.

Obviously if there are alternative exit paths between intake and final nozzle then you can take more bleed air off and the engine face flow distortions will benefit along with the surge margin. 101 was fairly 'leaky' in this respect, particularly around the thrust reverser buckets on the original nozzle design. This meant that 101's intake distortions were lower than the production aircraft so she could fly faster without surge - at least with the first attempt at intake control 'laws'. We managed to tweak most of the margin back eventually. Engine bay leaks were good for surge margin but VERY bad news for m.p.g.!

Here are a couple of diagrams to show what I mean. the first shows the surge lines for the various aircraft variants and also the N1 limiter Dude was talking about. NB: the X-axis is LOCAL Mach Number not freestream. The difference comes from the compression of the underwing flow by the bit of the wing ahead of the intake. Mmo + 0.2 is shown

">The next shows the surge free boundaries in sideslip and normal acceleration. You can see the zero 'g' capability Dude was enthusing over.

">The next shows the surge free boundaries in sideslip and normal acceleration. You can see the zero 'g' capability Dude was enthusing over.

">

">

As for 'high speed stall', I don't think we ever contemplated trying it! Our requirements in 'g' capability were defined and that was it. Besides, the aircraft would fly like the proverbial stone-built outbuilding at those sorts of conditions so I don't think one would have been able to get anywhere near a stall in the conventional sense. Stall as commonly defined for subsonics (deterrent buffet) might have been another matter, but I don't remember anything.

Cheers

Last edited by CliveL; 13th January 2011 at 11:17 . Reason: additional explanation

Subjects

AICU (Air Intake Control Computer)

Bleed Air

Engine surge

FL600

Fatigue

Intakes

Mmo

N1 (revolutions)

Nozzles

Sideslip

TMO (Temprature Max Operating)

Thrust Reversers

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 13, 2011, 20:12:00 GMT

permalink Post: 6177922

There really isn't any significant maintenance on the LE apart from de-icing mats ahead of the intake and they are all inboard of the kink

Subjects

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 13, 2011, 20:23:00 GMT

permalink Post: 6177940

From the angle the 'kinky' photo was taken the outer sweep of the ogee wing is towards the camera before sweeping aft to the drooped and washed-out tips and it looks like a kink in the LE sweep. The actual shape is seen better in the picture above. I've spent hours studying our G-BOAC at Manchester and to me the wing is a complex and lovely blend of curves and slopes, with no sudden changes such as a kink would require. Standing under the wing and observing it closely, no kink is apparent.

The wash-out on the tips shows particularly well in the above photo (washout is a forward twist of the wing at the tips to reduce the angle of attack of the tips compared to the rest of the wing, to prevent tip-stalling).

A question I have, relating to the photo above, is about the LE. The LE definately 'droops' in the area ahead of the intakes (it doesn't do so nearer the roots or tips). Is this to provoke a clean flow-breakaway in this area at high angles of attack to encourage the votices to form at this point as the wing transitions to vortex lift?

M2Dude Thanks for the kind words and careful explanations. I take it from your description of the anti-skid that once the mains start to rotate the brakes can be used, as the anti-skid comes 'off' (mains no longer think they are skidding).

I thought there was protection to prevent brake use until the nose wheels have landed, else brake application with the nose high would cause a rapid nose-down pitch, slamming the nosewheels on! Is there any such protection?

Last edited by Shaggy Sheep Driver; 13th January 2011 at 21:41 .

Subjects

Anti-skid

Braking

G-BOAC

Intakes

Vortex

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 14, 2011, 08:29:00 GMT

permalink Post: 6178845

The prototype had even more 'droop' in front of the intakes, but that produced a vortex at low incidence (near zero 'g') that went down the intakes and provoked surge.

Cheers

Clive

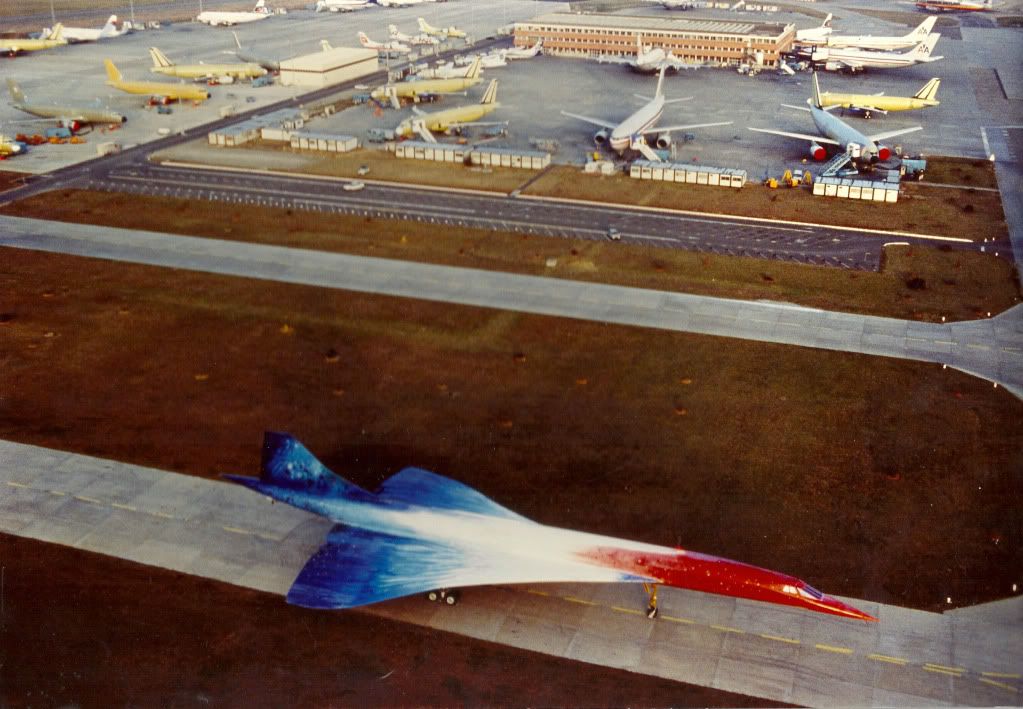

PS: Everyone seems to be adding their favourite Concorde photograph so I thought I would be different and add my LEAST favourite

">

">

Last edited by CliveL; 14th January 2011 at 08:43 . Reason: adding a photo and additional remarks

Subjects

C of G

Engine surge

Intakes

Trim

Vortex

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 18, 2011, 07:50:00 GMT

permalink Post: 6186441

I spent a lot of time on this in the 80s, but really one has to assume that Sir Lancelot put the Philosopher's Stone in the Holy Grail and buried it under the (other) end of Finnegan's rainbow and that YOU KNOW WHERE TO DIG!

When I left it the project looked a lot like this photograph that Christiaan found and posted on another site:

About 200 PAX, area ruled fuselage, new wing planform, flaps maybe, canard/foreplane, new shorter/lighter intake design,separate nacelles, new materials (probably not composites), digital avionics etc. but most of all a revolutionary new engine concept that nobody has invented yet. This engine has to produce lots of quiet thrust for airfield operation (low specific thrust) and lots of thrust with low frontal area for cruise (high specific thrust). Any takers?

Cheers

CL

Subjects

Avionics

Intakes

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

January 18, 2011, 09:30:00 GMT

permalink Post: 6186581

Clive, you really surprise me when you say you don't think that composites would be used from a future SST, is there a material reason for this? (I'm curious because being of a simple avionic brain, I always assumed composites would be used. But if anyone knows this stuff, you certainly would Clive

).

).

To answer Mike-Bracknell's original query, as far as avionics goes we can really go to town. For her age Concorde had some truly amazing aircraft systems, for instance the flying controls. To enable mechanical control (both FBW channels failed) there was a highly complex and heavy mixing unit under the rear floor. (To mix pitch and roll pilot mechanical demands into differential elevon demand inputs). This of couse would have to be done away with, as well as the relay jacks and replaced with a pair of side-sticks. (See posts on previous page). A 2 crew operation would obviously be the way to go, but neither desirable or possible in my view when Concorde was designed.

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

A triplex or quadruplex flying control system (possibly even integrating autoflight) would replace the Concorde collection of several analog boxes with a very small handful of lightweight digital units.. The powerplant control will have major weight savings, just take a look at this lot. 8 Engine Control Units, 4 Bucket Control Units, 2 Nozzle Angle Scheduling Units, 4 Reheat Amplifiers, 8 AICUs, 4 Air Intake Sensor Units and a single Air Intake Test Unit could potentially be replaced by just 4 multi-channel EEC type units. (On subsonic aircraft the EECs are mounted on the engine itself, not sure if that's a good idea for an SST, given the operating environment. Air Data and Navigation systems take a major simplification and weight saving, the 3 INUs and 2 ADCs (All of them straight from the 'rent a hernia' store as far as weight goes), could be replaced by a single ADIRU and a SAARU. The fuel indication/management side of things (2 FQI packs, 2 level switching packs and 3 CG computers) would probably be replaced by a single Fuel Processing unit. Ahhhh perchance to dream

Best regards

Dude

Subjects

ADC (Air Data Computer)

AICU (Air Intake Control Computer)

Afterburner/Re-heat

Avionics

C of G

Elevons

FBW (Fly By Wire)

Intakes

Nozzles

Thrust Reversers

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.