June 29, 2025, 20:57:00 GMT

permalink Post: 11913194

Can anything so closely placed together be considered separate when looking at an outlier event?

Everyone is looking for something that would shut off both engines at the exact same time. This installation could, it is the closest the 2 systems get in proximity, physically and electrically, at least and it seems we don\x92t know a whole lot about it.

Obviously, since the thrust levers are placed next to each other - the separation that's available in the center console is limited, but as soon as the wiring exits that constrained area, the separation increases. Furthermore, the same engine-to-engine wiring separation also applies to channel A/B FADEC channels, as well as the fuel switch/fire handle wiring.

All these requirements are documented in the Boeing DR&O (Design Requirements and Objectives) - and there is an audit done late in the design process to insure compliance.

In short, you're barking up a tree stump - there is nothing there.

Subjects

FADEC

Fuel (All)

Fuel Cutoff

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 30, 2025, 04:42:00 GMT

permalink Post: 11913342

That's a pretty big "if" but here's the patent drawing:

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 30, 2025, 07:32:00 GMT

permalink Post: 11913383

I expect that this is also true for the 787. Can anyone confirm this?

Subjects

FDR

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 30, 2025, 10:56:00 GMT

permalink Post: 11913487

Subjects

Fuel (All)

Fuel Cutoff

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

June 30, 2025, 14:59:00 GMT

permalink Post: 11913644

There are several ways that the HPSOV can close:

An EEC (engine ECU) can close the upstream Fuel Metering Valve (FMV) electronically, so the HPSOV will lose its opening pressure.

The HPSOV can be acted on by a Shutoff Solenoid Valve (which directs fuel pressure in an opposite manner to the pressure coming from the Fuel Metering Valve).

Unfortunately, the diagram I am using is truncated, and I can't see if the Shutoff Solenoid Valve is magnetically latched in its last commanded position like typical fuel shutoff valves. Nor can I see what controls it. I suspect things like the respective cockpit fire handle and fuel cutoff lever, but also EEC commands.

There is probably a copyright on the diagram, so I won't post it here. Perhaps someone can fill in the gaps for me?

Subjects

FCOM

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

GEnx (ALL)

High Pressure Shutoff Valve

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 01, 2025, 13:55:00 GMT

permalink Post: 11914255

Not really relevant to what you quoted though, as the scenario in question requires:

-

Engines running on centre tank fuel during takeoff

while the aircraft is operating normally

- We don't know for certain if this is the case. It seems to be but it's not something that happens on other families.

- Then, total AC failure stopping fuel boost pumps.

- Engines suction feed from contaminated/full-of-water wing tanks.

The aircraft has two engines and should be able to climb out on one, plus it dropped like a rock . 'Significantly degraded' thrust isn't really compatible with what we saw. You'd also expect the engines to recover pretty quickly as it leveled off.

The limitations at high altitude are primarily air/volatiles degassing out of the fuel. That's not going to be much of an issue at sea level, even if the engines are a bit higher up during rotation.

APU is a nice-to-have; it's on the MEL. If you lose all four generators, it's because of some major carnage in the electrical software/hardware and chances of putting the APU on line even if it's operating are very slim.

- The specific 248-day integer overflow was patched, and before the fix was rolled out, the AD required this system to by power cycled every 120 days to prevent overflow

- The PCU software still has the functional requirement to be able to command all AC GCUs to enter failsafe mode, this means that while the initial bug was fixed, the ability for this particular software system to command the same result is still a functional part of the architecture - presumably for safety management of the AC system

- This was not the first or last "software overflow error" issue in Boeing or even in the 787

I do agree that the engine driven pumps should be able to provide fuel alone, the whole point of these pumps is to keep the plane flying within some limitations, high altitude is one of those limitations, I propose that there may be others based on the following:

- Some more knowledgable people here have proposed or countered vapour lock, fuel contamination and automatic fuel cut-off theories to various degrees - even if these are not enough on their own, loss of electrical during rotation at high temperature could combine with these in a way we have not yet considered

- Thrust is nonlinear, and while I'm not qualified to say how much loss of fuel flow or loss of thrust would be critical in this scenario we do know that it was a hot takeoff with significant weight and gear remaining down - I know others here have run sims but I don't think anyone has focused on specific thrust / fuel flow params

- While electric fuel pumps might not be physically necessary for takeoff, my final point is: why are they required for takeoff? Is it not to mitigate cavitation, fuel sloshing at rotation, or any other kind of problem that might be relevant here?

Subjects

APU

Air Worthiness Directives

Centre Tank

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Generators/Alternators

MEL

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 01, 2025, 14:08:00 GMT

permalink Post: 11914265

- The specific 248-day integer overflow was patched, and before the fix was rolled out, the AD required this system to by power cycled every 120 days to prevent overflow

- The PCU software still has the functional requirement to be able to command all AC GCUs to enter failsafe mode, this means that while the initial bug was fixed, the ability for this particular software system to command the same result is still a functional part of the architecture - presumably for safety management of the AC system

- This was not the first or last "software overflow error" issue in Boeing or even in the 787

- Some more knowledgable people here have proposed or countered vapour lock, fuel contamination and automatic fuel cut-off theories to various degrees - even if these are not enough on their own, loss of electrical during rotation at high temperature could combine with these in a way we have not yet considered

- Thrust is nonlinear, and while I'm not qualified to say how much loss of fuel flow or loss of thrust would be critical in this scenario we do know that it was a hot takeoff with significant weight and gear remaining down - I know others here have run sims but I don't think anyone has focused on specific thrust / fuel flow params

- While electric fuel pumps might not be physically necessary for takeoff, my final point is: why are they required for takeoff? Is it not to mitigate cavitation, fuel sloshing at rotation, or any other kind of problem that might be relevant here?

Cavitating destroys pumps rapidly - someone upthread said replacing the fuel pump immediately is SOP if it has suction fed. Expect end of life in tens of hours rather than tens of thousands.

Some aircraft have switched to using jet/venturi pumps powered by returned fuel, like the A220. The electric boost pumps there are mainly for redundancy and are shut down in cruise; only one in each wing tank. Some A320s replace the centre override pumps with venturi transfer pumps.

Subjects

APU

Air Worthiness Directives

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 09, 2025, 20:05:00 GMT

permalink Post: 11918581

Edit: And here it is:

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 09, 2025, 22:34:00 GMT

permalink Post: 11918651

Edit: And here it is:

For those unfamiliar with cockpit controls in general, I\x92ll leave my \x93schematic\x94 image to show the principle of \x93lift-and-move\x94 the toggle vice just pushing the toggle in a desired direction.

Cheers,

PJ2

Last edited by PJ2; 9th July 2025 at 22:45 . Reason: for context

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Honeywell

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 09:26:00 GMT

permalink Post: 11918827

I'm not saying that this happened to this crew but it certainly could happen to someone. People do weird !!!! under high stress. There is an initial "oh !!!!, what's going on" then the training kicks in. Often at super fast rate and the challenge becomes slowing it all down.

The bloody master warning on the Airbus for smoke in the forward Lav used to get me everytime. Was always at night over the ocean too.

Subjects

Dual Engine Failure

Engine Failure (All)

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Memory Items

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 12:42:00 GMT

permalink Post: 11918961

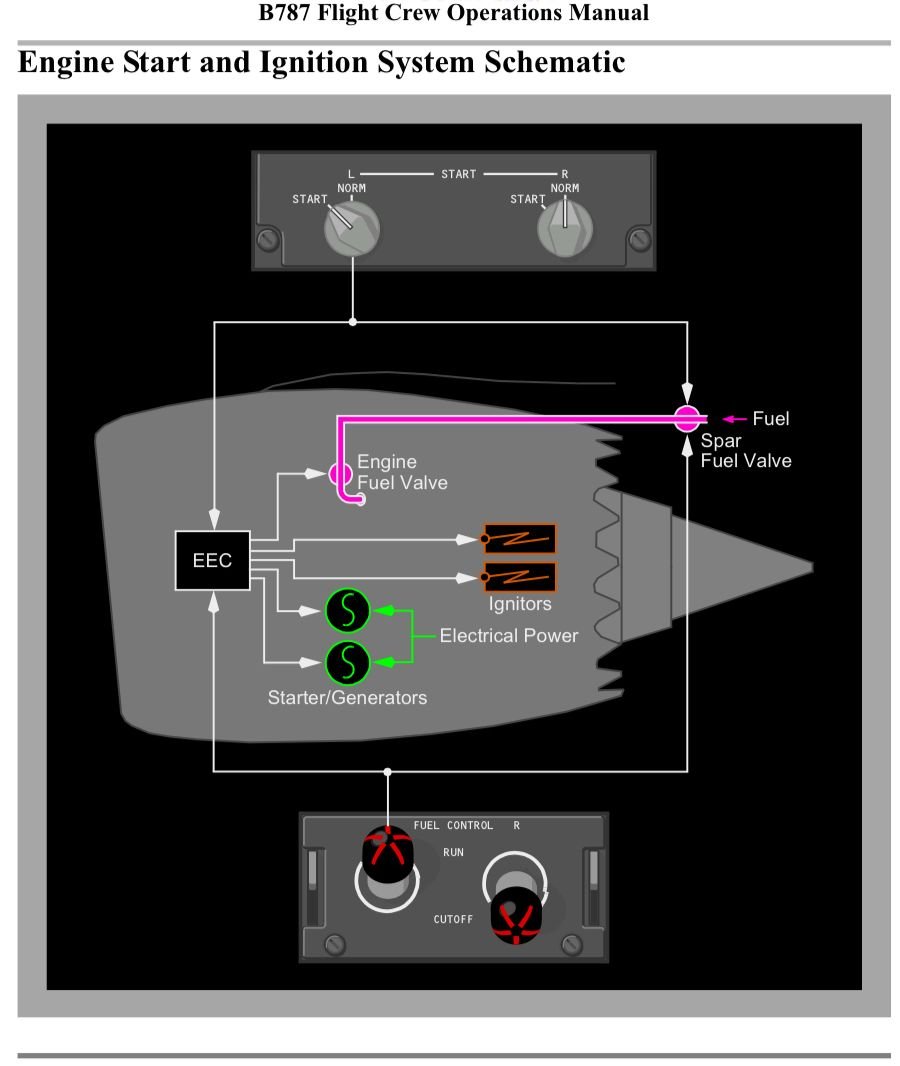

The above checklist procedure implies throttle lever angle and cutoff switches are independant for resetting FADECs.

If so, is it time for this convention from the days where throttles and cutoffs were mechanical systems, not resolvers and switches, to end?

Risk vs reward? Requires more coordination between PF and PM in cases where cutoff is not desired by PF- keep throttle/s up, cannot be surprised by a fuel cutoff.

Last edited by moosepileit; 10th July 2025 at 12:53 .

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 12:53:00 GMT

permalink Post: 11918969

The above checklist procedure implies throttle lever angle and cutoff switches are independant for resetting FADECs.

If so, is it time for this convention from the days where throttles and cutoffs were mechanical systems, not resolvers and switches, to end?

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 12:58:00 GMT

permalink Post: 11918976

The above checklist procedure implies throttle lever angle and cutoff switches are independant for resetting FADECs.

If so, is it time for this convention from the days where throttles and cutoffs were mechanical systems, not resolvers and switches, to end?

Risk vs reward? Requires more coordination between PF and PM in cases where cutoff is not desired by PF- keep throttle/s up, cannot be surprised by a fuel cutoff.

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Spar Valves

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 13:31:00 GMT

permalink Post: 11918989

The switch itself is 4-pole, or a double-on, double-on switch, capable of independentently signaling whrough completely isolated poles. The plot thickens. IF the switches really are involved, there is either some kind of shortcut in within the LRU/very messed up witing harness, some freak automated muscle memory thing or deliberate action.

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Muscle Memory

Spar Valves

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 14:04:00 GMT

permalink Post: 11919015

Changes:

- Built the thread up to July 10, 2025, 12:31:00

- Add subjects: Relight, 51 Day Issue, Fuel Cutoff Switches (detent), ICAO, Fuel Cutoff Switches, Memory Items, Annex 13, Simulation Scenarios.

- Various technical fixes should give a better/more accurate presentation.

Raise issues here https://github.com/paulross/pprune-threads/issues or PM me.

Subjects

Annex 13

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Fuel Cutoff Switches (detent)

ICAO

Memory Items

Relight

Simulation Scenarios

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 14:45:00 GMT

permalink Post: 11919035

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Spar Valves

TLA (Thrust Lever Angle)

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 16:10:00 GMT

permalink Post: 11919084

I'm trying to mix the best of the old and the new.

Fast, erroneous, uncoordinated or nefarious- gives a way to intervene, without changing the standards.

Throttles are no longer mechanical. Keep them forward off idle and the cutoff switch does nothing.

Fire/fail/flameout/stall- PM takes the confirmed bad throttle to idle. Then, if appropriate, fuel cutoff and then continue with the fire switch that should also isolate fuel before the engine, air, hydraulics, and electrics.

Bias- I've had mechanical fuel cutoff, mechanical throttles and mechanical isolations- DC9.

Electric throttles, fuel cutoffs and mechanical isolations- C-17s and MD-11s.

Have not had all electrical on switches, throttles and electrical circuits for isolation, only- which allows for more options and unintended consequences.

Last edited by moosepileit; 10th July 2025 at 16:24 .

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Spar Valves

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 10, 2025, 17:26:00 GMT

permalink Post: 11919126

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Links are to this post in the relevant subject page so that this post can be seen in context.

The thread is closed so there are no user likes are available and no reply is possible.

July 11, 2025, 21:30:00 GMT

permalink Post: 11919765

In the cockpit voice recording, one of the pilots is heard asking the other why did he cutoff.

The other pilot responded that he did not do so.

Subjects

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

Pilot "Why did you cut off"

Preliminary Report

RUN/CUTOFF

Timeline (Preliminary Report)

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.

July 11, 2025, 21:40:00 GMT

permalink Post: 11919771

- on take off roll both engines lost power as the fuel cut offs went from RUN to cutoff

- CVR recorded one pilot asking why they had gone to CUTOFF

- within 10 seconds the fuel cutoff was moved back to RUN

-RAT was deployed, APU had begun auto start

- 32 seconds after Vr the MAYDAY was called

This should also dispel a lot of the comments about AAIB-India, Indian culture in general and general competence. For a preliminary report this is far more thorough and extensive than what would normally be expected and they\x92ve kept Boeing, GE, FAA and investigators from US, UK, Canada and Portugal in the loop from the start

They have also clarified why it took so long to do the EAFR download- because of the extensive damage they had to source specialist equipment from the NTSB that only arrived on the 23rd of June (they downloaded on the 24th) so all that talk of a \x91coverup\x92 is pretty embarrassing now

of course the big question is why/how those switches were commanded into cutoff in the first place the exact sequence at Vr is the most critical, there hasn\x92t been much scrutiny at all that I can see in the Indian/international media of the personal

background of the flight deck crew which has happened in other suspected pilot initiated disasters in the past, I guess this is an avenue investigators will have been doing themselves

Subjects

APU

CVR

EAFR

FAA

Fuel (All)

Fuel Cutoff

Fuel Cutoff Switches

MAYDAY

NTSB

Preliminary Report

RAT (All)

RAT (Deployment)

RUN/CUTOFF

Links are to this post in the relevant subject page so that this post can be seen in context.

Reply to this quoting this original post. You need to be logged in. Not available on closed threads.